Codelco of Chile is planning a 25% reduction in its indirect emissions by 2030 as a component of its decarbonization strategy. Codelco is the largest copper producer, and its mining activities lead to pollution. Copper plays an essential role in solar panels, wind turbines, and energy transmission because of its conductivity and long-lasting properties. It also plays a role in electric vehicles, charging systems, and battery storage options. This positions it as an essential element in Chile’s shift towards renewable energy. Codelco implements several strategies and programs to lower emissions from copper extraction. It is shifting to renewable energy resources for its activities. This involves signed contracts with renewable energy suppliers to deliver solar, wind, and hydropower to its mines. For example, Codelco’s Chuquicamata and El Teniente mines use renewable energy to decrease emissions. A ball clevis acts as a link between insulators and transmission line equipment.

Copper mines need high-voltage power lines to transport electricity from power plants to remote mining sites. A ball clevis supports high-voltage power transmission systems supporting Chile’s copper mining decarbonization. The clevises ensure the mechanical stability and electrical insulation of power lines. Ball clevises help to maintain secure connections in transmission lines to reduce downtime. They are able to withstand extreme environmental conditions such as high temperatures and storms. A ball clevis helps in interconnecting microgrids that integrate renewables with mining operations.

The roles of a ball clevis in Chile’s copper mining decarbonization

A ball clevis is a mechanical component used in mining equipment. The clevis ensures the efficiency, reliability, and precision of mining equipment. This helps support the transition to more efficient,. electric, and automated systems. Ball clevis contributes to reducing energy consumption, reducing emissions, and promoting sustainable mining. Here are the roles of ball clevis in copper mining and decarbonization in Chile.

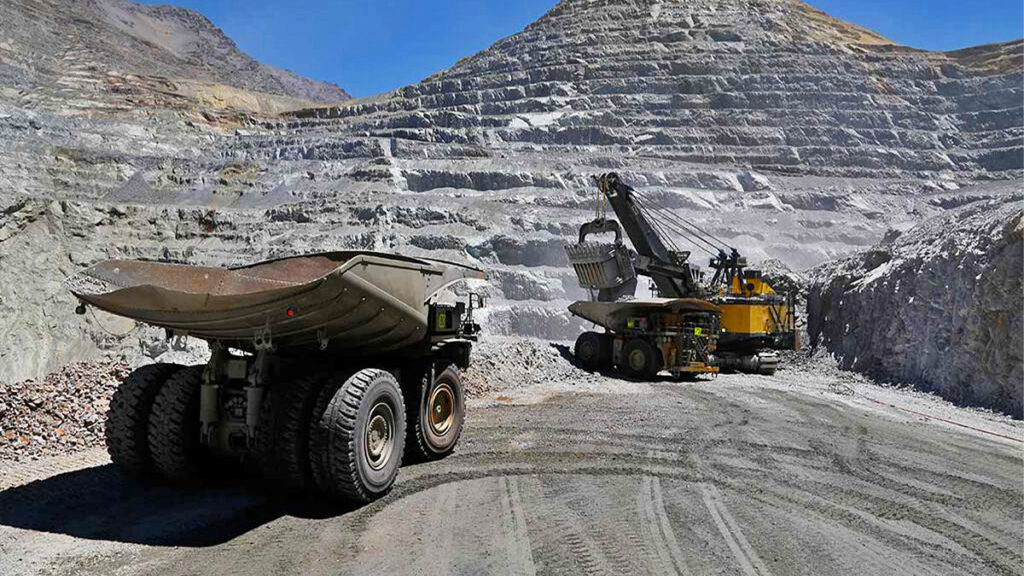

- Enhancing equipment efficiency – the ball clevis serves in linkages and control systems of heavy machinery. It helps reduce friction and wear, which leads to more efficient operations of mining equipment. Supporting machinery such as haul trucks, excavators, and conveyor systems helps reduce greenhouse gas emissions.

- Supporting electrification of mining equipment—the ball clevis ensures the reliability and performance of new systems. Electric machinery needs precise control mechanisms supported by ball clamps.

- Reducing maintenance and downtime—high-quality ball clevis provide durability and reliability. It reduces frequent need for maintenance and likelihood of equipment failure. Fewer replacements and repairs mean lower resource use and waste.

- Easing automation and smart mining—the clevis ensures the accurate operation of robotic arms, autonomous vehicles, and other automated equipment. Automation optimizes mining operations, leading to more efficient use of energy and resources. Smart mining technologies help reduce energy waste and emissions.

Codelco’s efforts to lower emissions from copper extraction in Chile

Chile’s Codelco has been enacting various measures to lower emissions from its mining activities. These initiatives are a component of its larger dedication to sustainability and adherence to Chile’s national decarbonization goals. The measures adopted will aid in reducing emissions and establish Codelco as a leader in sustainable mining methods. TTF is a world-class global provider of high-quality overhead line hardware, transmission hardware, distribution hardware, conductors, insulators, cutout switches, anchoring and grounding products. These are crucial components are crucial in the decarbonization efforts in chile’s mining. Outlined below are the main strategies Codelco is implementing to reduce emissions.

- Electrification of mining machinery—Codelco is substituting diesel-operated trucks, loaders, and heavy equipment with electric versions. The firm is additionally utilizing electric tools like drills and load, haul, and dump vehicles to lower diesel usage.

- Codelco has established long-term contracts with renewable energy suppliers to provide its operations with solar, wind, and hydropower. It is additionally investigating the setup of solar panels at mining locations to produce clean energy on-site.

- Improvements in energy efficiency—Codelco is implementing cutting-edge technologies and process enhancements to lower energy usage in its mining operations. It is additionally investing in contemporary, energy-efficient machinery and upgrading older equipment. This helps to enhance performance and cut energy consumption.

- Carbon capture and storage—the firm is exploring the viability of carbon capture and storage methods. These methods help to reduce emissions from its activities. This technology has the potential to cut emissions from processing facilities.

- Digital transformation and automation—Codelco is leveraging digital technologies like IoT, AI, and automation to enhance its operations. Utilizing autonomous trucks and drills enhances efficiency and decreases fuel usage, resulting in reduced emissions.