Last passage, we mainly introduce the type of the suspension clamp. In this passage, we will still talk about other type of suspension clamp. Another topic in today’s passage is how to choose a good suspension clamp, which is the important part.

Other type of suspension clamp

CTS Double Wire Jumper Suspension Clamp

C stands for suspension clamp

T stands for fixed

S stands for corona type

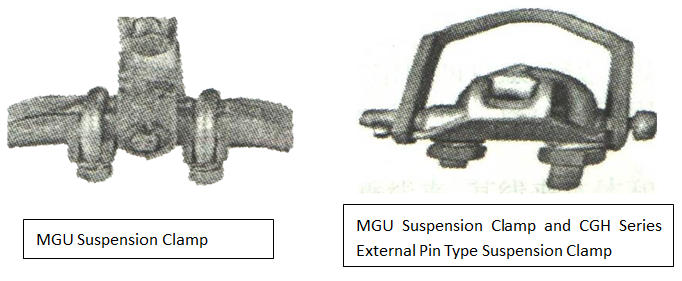

MGU Suspension Clamp and CGH Series External Pin Type Suspension Clamp

MGU type suspension clamp mainly used for overhead power lines and substation. They suspend the conductor and the lightning protection wire on the insulator. They also light protection wire on the tower by connecting the hardware. The material is melleable cast iron and aluminum alloy.

Wedge Suspension clamp

This kind of clamps hangs the wire on the linear pole tower in the heavy snow area. The wedge suspension clamp used on the linear tower with the huge tensile strength.

Wear-resistant Suspension Clamp

Materials:

clamps and plate—melleable cast iron; cosed pin—stainless steel; spare parts—steel

All the materials are againest corrosion with hot-dip zinc coating.

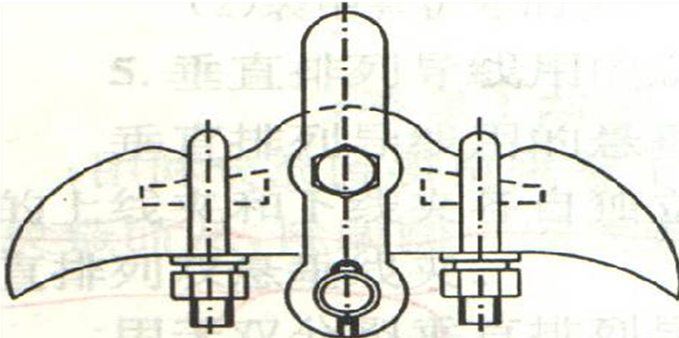

Suspension Clamp for Vertical-based Conductors

They include bolts from two suspension clamps and a pair of hangers. The top clamp and bottom clamp hang without interfere.

The advantage of installation and usage:

Reduce cost by using two stereotyped clamp with making two plates only.

The independent design of the upper and lower clamp makes the hull roated around the center.

The clamp can lean to the side with higher tension when the tension of two sides is imbalance. The higher tension can avoid the extra bending movement of hanging plate. The movement may result in the inability of the clamp to be offset.

The independent of the clamp provide the convenience for line channeling. It is also convenience for construction, operation and maintenance.

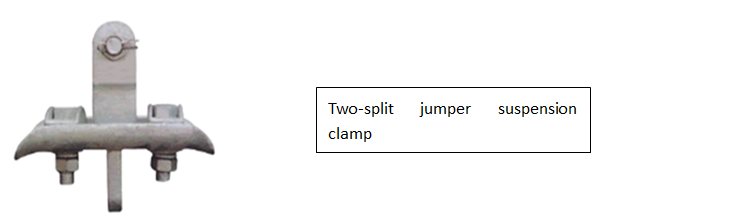

Jumper Suspension Clmap

As the voltage level rises, the conductors of each phase in the line progress from two-split to three-split, four-split, six-split, and eight-split.

The suspension clips for split jumpers suspend split conductors.

The suspension clamp for double split jumper can solve the technical problem. The problems are the installation of dry-shaped tower, tension tower and corner tower. They are easy to damage and uneven in the construction of power transmission line.

The suspension clamp for split conductor is convenient in installation. It also has reasonable structure and got the beautiful shape of the jumper.

There are other three type of jumper suspention clamp. They include four-split jumper suspension clamp, jumper brackets and overhead line suspension clamp.

Suspension Clamps for Large Span and UHV Lines

Large span: the span is over 1000 meter and the height may reach 100 meter.

Why use: the wire needs to bear a large tension. We need to make sure the wire clamp release the wire when the wire break down. The wire clamp also have a large hanging angle and a large radius of curvature.

Suspension Clamp for Large Span with Single Cable

Types: Multi-pulley; Crawler; Roller

We analyze the stress of the lower pulley, roller and crawler calmps on the wire. The main difference lies in the number of fulcrums and the degree of density. The density includes “sparse”, “dense” and “very dense”.

When the fulcrum reaches a certain density, the stiffness of the wire plays a considerable role. Then the radius of curvature of the wire is close to the radius of the clip.

Choose of Suspension Clamp

Select on types and structure

The suspension clamp shoud able to bear the full load of the wire when hanging the wires.

The wire cannot slide in the clamp or get out of the insulator string. This is because the system is in normal operation or broken.

When hanging the lighting protection line, the suspension clamp can support the whole load of the lighting protection line within the vertical span.

The lighting protection wire is not allowed to slide in the wire clip when the tension is unbalance.

Suspension Clamp Should have Enough Mechenical Strength

Suspended clamps could bear the combined load. The loads contains vertical and horizontal loads of conductors or lightning conductors.

The majority load of the conductor or lightning protection line may occur. After considering the safety factor, it should not be less than or equal to the failure load of the wire clamp.

Majority load is the comprehensive value of the self-weight, ice-covered weight and horizontal wind load of the guide line or lightning protection line. The national standard is the safety factor of mechanical strength. The safety factor under normal conditions is 2.5.

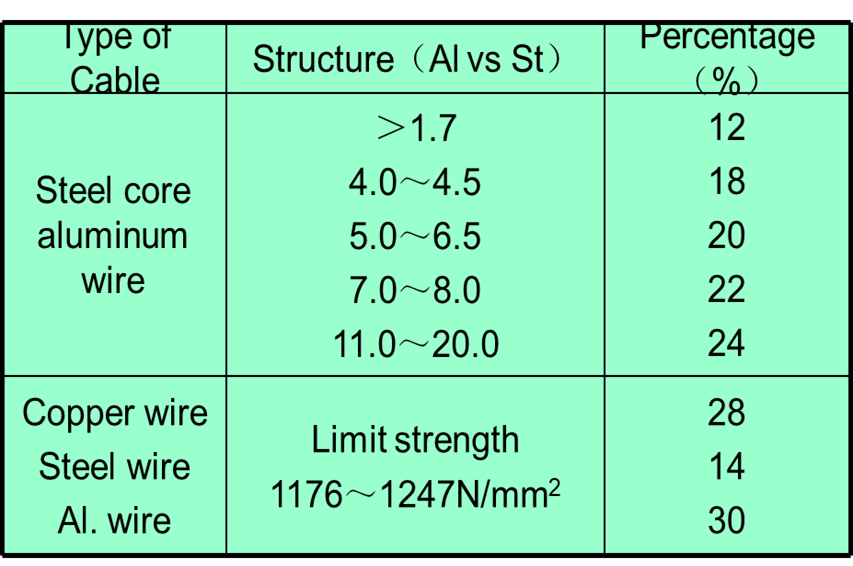

Suspension Clamp Should have Standard Grip Strength

Grip strength refers to the determination of the grip strength value of the clamp. The clamp on the conductor install under the specified test conditions.

The suspension clamp should have a certain grip on the wire or the lightning protection wire. The grip on the lightning protection wire have uneven icing or uneven sealing load. The sealing load is under the condition of line operation. This means the wire should not slip out of the wire clamp under such conditions.

Suspension Clamp should have a Suitable Angle

Suspension angle:

Suspension angles of the strands on both sides of the suspension point may fluctuate. This is becuase the differences between the span and height of the tower. This difference induce by terrain variation. Another reason is the changes in the conductor and lightning protection wire due to ambient temperature and load change.

The method to avoid the damage of the stranded wire is to increase bending stress at the outlet of the clamp. Thus, a necessary check should carry out. The check ensure the actual hanging angle of the outlet on both sides of the wire clip. To make sure it meet the national standards.

National standard is the suspension angle of the suspension clamp. The angle should not be less than 250. The suspension clamp’s curvature radius should be at least 8 times the diameter of the installed wire.