A b strand ground clamp is a type of grounding device used to establish a reliable electrical connection between the overhead conductor and the ground wire. This helps to ensure the line is properly grounded for safety and operational reasons. It consists of a metallic body with a set screw mechanism that runs parallel to the transmission line conductors. It also provides an effective path for fault to safely dissipate into the ground. This is important to prevent electric shocks and reducing the risk of damage to the equipment. It is from materials such as aluminum alloy, stainless steel or copper. The choice of material depends on factors like environmental conditions in South America. Examples include parallel groove clamp, bolted b strand ground clamp, compression type clamp and hydraulic b strand ground clamp. They find use in applications such as transmission lines, lightning protection and fault current pathway.

Key features of b strand ground clamp

B strand consists of various components that make them a suitable choice in the various applications. It is important to assess the various features to ensure they meet the specific requirements for your application. The following are the key features of a b strand ground clamp.

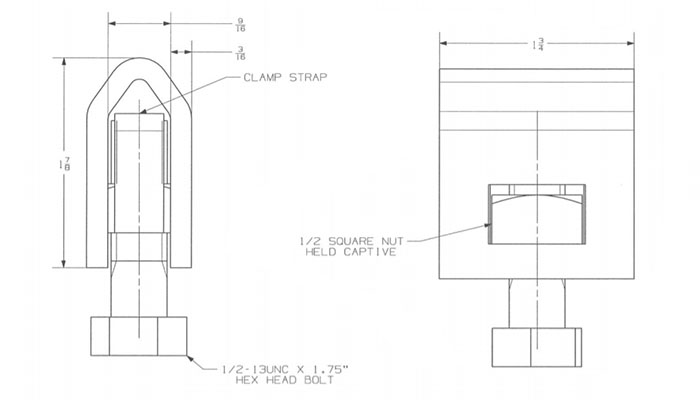

- Design – they have designs to securely attach the supporting strand of the overhead transmission line. It includes parallel groove clamps, compression mechanisms, bolts or hydraulic systems.

- Grounding effectiveness – the main function of the ground clamps is to establish a low-resistance path for fault currents to dissipate into the ground. The design and materials contribute to the grounding effectiveness of the clamp.

- Corrosion resistance – the clamps may have coatings of materials to protect the b strand ground clamps. It protects them from weather and environmental conditions to ensure reliability of the clamp.

- Material – it is from various materials that are durable and corrosion resistant. These materials include stainless steel, copper or aluminum alloy.

- Versatility – the versatile design allows them to accommodate various sizes for use in different applications.

- Lightweight – this allows for ease of handling and installation in overhead transmission lines.

- Easy installation – they also have straightforward designs to allow for simple installation on the various applications.

Selection and installation of b strand ground clamp

Proper selection of the b strand ground clamps helps to ensure proper functionality and safety. It also helps to ensure effective grounding and promoting safety in the system. It includes considering various features such as compatibility with strand size, material and corrosion resistance, grounding effectiveness and manufacturer reputation. The installation process should enhance safety and proper procedures of the application. The following is a general installation process of the b strand ground clamps.

- Preparation – gather all the necessary tools required for the installation. This is including the b strand ground clamp, wrenches, safety equipment and lineman’s tools.

- Grounding point location – identify the suitable location on the overhead transmission line’s supporting strand.

- Strand preparation – inspect the supporting strand for any damage or corrosion. Clean the strand to ensure good electrical connection.

- Clamp preparation – set the adjustable mechanism to the suitable size for the supporting strand.

- Clamp positioning – place the b strand ground clamp onto the supporting strand at the predetermine location.

- Clamp tightening – use wrenches to tighten the set screws or bolts on the clamp securely.

- Inspection – visually inspect the installed b strand ground clamp to ensure secure attachment to the supporting strand.

- Electrical tests – conduct electrical tests to verify the effectiveness of the ground connection. This is through following the testing procedures.

- Documentation – keep a record of the installation details including the date, location and any tests results.

Maintenance and inspection of b strand ground clamps

Conducting regular maintenance and inspection helps to ensure the continued effectiveness in grounding. The diverse environmental conditions in South America influence the frequency of this activity. It also helps to identify and address potential issues that could lead to potential failures and accidents. Additionally, it is advisable to perform periodic professional maintenance and inspections. The following is a basic guide for maintenance and inspection of b strand ground clamps in South America.

- Periodically inspect the b strand ground clamps for signs of physical damage, corrosion or wear. Check for cracks, rust or other visible issue.

- Ensure the set screws, bolts or other tightening mechanisms on the clamps are securely fastened.

- Verify that the clamp has not undergone any deformation that could affect its ability to maintain a secure connection to the supporting strand.

- Check for deformation to ensure it does not affect its ability to maintain a secure connection to the supporting strand.

- Check for signs of damage to the insulation and inspect for cracks, tears or degradation that could compromise the insulation.

- Consider the environmental conditions to which the clamp is installs. Pay attention to corrosion resistance and protective coatings.

- Clean the b strand ground and the supporting strand to remove dirt, dust or other contaminants using a soft brush to avoid damaging the clamp.

- Apply corrosion inhibitors as recommended to prevent effects of corrosion in harsh environments.

- Periodically retighten the set screws, bolts or other fastening mechanisms to ensure the clamp maintains a secure connection.

- Maintain detailed records of all inspection, maintenance activities and any testing results. This helps to keep track of the history of the ground clamp and for compliance purposes.

Comparative analysis of b strand ground clamps

Conducting a comparative analysis involves assessing and evaluating various features, specifications and performance characteristics. They help to ensure proper selection to best fit your application needs. Additionally, it is advisable to consult with manufacturer guidelines and industry standards during the selection process. The following are the key factors to include in the comparative analysis in South America.

- Material composition – compare the materials used in different b strand ground clamps. These include aluminum alloy, stainless steel or copper. Assess each advantage and disadvantage of each material to your application.

- Size and compatibility – evaluate the range of strand sizes that each clamp accommodates. This helps to provide flexibility in different applications.

- Ease of installation – compare the ease of installation for each b strand ground clamp to simplify the installation process.

- Grounding effectiveness – evaluate the design and features that contribute to the grounding effectiveness of each clamp.

- Versatility – assess the versatility of each b strand ground clamp. This helps to provide adaptability to different transmission line.

- Cost – compare the costs of each b strand ground clamp considering features and specifications offered.

- Design and construction – analyse the design and construction of the clamps. Consider factors such as securing mechanisms and presence of insulation.

- Corrosion resistance – assess the corrosion resistance of each clamp. Consider the potential exposure to environmental conditions.

Certifications and standards in South America

There are various certifications and standards that govern the use of b strand ground clamps in South America. They also help ensure the durability, reliability and safety of the ground clamps. Each South American has their own standards for the use of b strand ground clamps. Also, it is advisable to consult with industry professionals for guidance on the various standards in the region. The following are the standards and certifications for b strand ground clamps in South America.

- IEEE standards – this provides standards related to power and energy systems. This covers standard practices for grounding of overhead transmission lines.

- ANSI standards – this are standards for various industries including electrical power systems. This is to provide guidelines for the grounding of meta supports.

- UL certifications – this is a global safety for testing and certifications. It ensures they comply with specific safety and performance.

- ASTM standards – these are standards for developing and publishing technical standards for various materials, products, systems and services.

- ISO certifications – this provides standards for quality management systems. It sets requirements for quality management to ensure consistent quality in the production of b strand ground clamps.

Regional market for b strand ground clamps in South America

There are various factors that shape the regional market for b strand ground clamps in South America. They affect the demand, supply and availability of the b strand ground clamps in the region. The following are the factors that influence this market.

- Electrical demand for electrical infrastructure – the rapid economic growth leads to an increase in the demand for electricity.

- The expansion of the mining industry – the growth of the mining industry leads to an increased demand for b strand ground clamps.

- Renewable energy sector – the growth of renewable energy sector leads to an increased demand in b strand ground clamps for grounding renewable energy installation.

Frequently asked questions

A b strand ground clamp is a type of electrical grounding device used to connect a conductor to a grounding electrode. It helps to provide allow resistance path for fault currents to flow to the ground.

The selection process of the b strand ground clamp involves considering several factors. These include environmental conditions, infrastructure requirements, regulatory standards, costs and supplier reputation.