A ball clevis is a hardware fitting or attachment used to connect various components of the electric transmission system. It provides a secure and flexible connection while allowing for rotation and articulation. It helps connect components such as insulators, conductors and other electrical transmission system hardware. A ball clevis consists of a ball-shaped end, a clevis pin and a cotter pin or locking mechanism. There are various factors that influence the material of the ball clevis. These include durability, corrosion resistance and weight. Common materials include steel and aluminum. Commonly used types include standard ball clevis, long clevis, short clevis, tension clevis, yoke clevis and swivel ball clevis. Utility companies in South American countries depend on ball clevises to maintain flexibility. This helps them withstand the region’s variable weather conditions and topography. They find use in construction of overhead transmission and distribution lines.

Key features of ball clevis

The main features of the ball clevis help to provide secure and flexible attachment. This is important for insulators, conductors and other hardware components. They also contribute to the flexibility, stability and performance of the ball clevis. The following are the key features of the ball clevis.

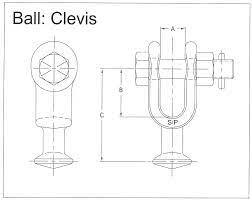

- Ball-shaped end – the ball-shaped end allows for rotational movement and articulation. This enables flexibility in response to dynamic forces such as wind-induced sway and conductor sag.

- Clevis pin – the clevis pin passes through the hole or socket in the ball end. It also secures the ball end in place while allowing it to pivot and rotate.

- Locking mechanism – the ball clevis has a locking mechanism that involves a cotter pin, snap ring and locking nut.

- Material – they are from materials that offer durability, strength and resistance to environmental factors.

- Load-carrying capacity – the ball clevis can hold varying load capacities depending on application. it ensures the clevis can support the weight and tension of the attached components.

- Types and sizes – they also come in different types and sizes to accommodate various applications and load requirements.

- Articulation – articulation allows the clevis to accommodate angles and deviations in electrical lines.

- Reliability – the clevis has reliability that ensure they maintain their structural integrity and performance over time.

- Safety – the locking mechanism and secure attachment provided by ball clevises contribute to safety in electrical systems.

Selection and installation of ball clevis in South America

The selection of ball clevises depends on various factors. They ensure that the chosen fittings are suitable for the specific application. These include application requirements, load capacity, environmental conditions, type and design, material, customization cost and local expertise. The installation should ensure safety and reliability of the infrastructure. The following is a step-by-step installation process of the ball clevis.

- Safety precautions – ensure to follow all the necessary safety precautions. This includes wearing appropriate personal protective equipment. Also, ensuring the area is safe and clear of hazards.

- Installation site – gain access to the installation site whether its on a utility pole or other structure.

- Inspection – inspect the ball clevis and other hardware to ensure they are in good condition and free from defects.

- Positioning – place the ball clevis at the desired location on the support structure.

- Insert the clevis pin – insert the clevis pin through the hole in the ball clevis, aligning it with the attachment point on the structure.

- Torque the fasteners – torque the nut and bolts to the manufacturer’s specifications to ensure it is secure and tight.

- Check articulation – ensure the installed ball clevis allows for proper articulation and rotation.

- Safety checks – inspect the installation to ensure it meets safety standards and regulations. This helps ensure there are no obstructions that could compromise safety or performance.

- Documentation – maintain detailed records of the installation process. This is including dates, location, inspection results and any deviations.

Maintenance and inspection of ball clevises

Proper maintenance and inspection ensures the continued reliability and safety of the systems. It also helps identify issues early and prevent equipment failures and electrical hazards. Additionally, it is advisable to conduct professional maintenance and inspection once in a while. The following is a basic guide to inspection and maintenance of ball clevis in South America.

- Conduct regular visual inspections of ball clevises to check for visible signs of damage, wear or corrosion. Check for cracks, rust or deformation.

- Verify that the ball clevis allows for proper articulation and rotation for holding movements.

- Inspect safety features to ensure they are functioning correctly and securely.

- Check the alignment of the ball clevis to ensure it is correctly oriented for its intended application.

- Periodically clean the ball clevis and its hardware to remove dirt, dust and debris. This helps prevent the buildup of contaminants that lead to corrosion.

- Check the ball clevis for signs of corrosion in regions with humid or coastal climates. Apply a protective coating to prevent further deterioration from corrosion.

- Inspect the clevis pin, cotter pin, locking nuts and other fasteners for wear, damage or corrosion.

- Ensure the threaded fasteners are properly torqued to the manufacturer’s specifications.

- Apply lubrication to moving parts such as the clevis pin to reduce friction and allow for smooth articulation.

- Assess the load-carrying capacity of the ball clevis to ensure it can support the expected loads without stress.

- Keep detailed records of inspections including dates, findings and any maintenance or repairs performed.

Comparative analysis of ball clevises in South America

A comparative analysis involves assessing various aspects of the ball clevises available. It involves considering the types, designs and intended application to select the best ball clevis. Additionally, it is advisable to consult with industry experts on the best selection of the clevises. The following are the key factors to include in a comparative analysis in South America.

- Types and designs – check the availability of different types and designs of ball clevises. The should suit various application and load requirements.

- Material – compare the materials used in the manufacture of the ball clevises. Assess the effectiveness of coatings to prevent corrosion.

- Load capacity – analyze the load-bearing capacity of different ball clevises models. This helps to ensure they meet the requirements of specific installations.

- Compliance – ensure the selected ball clevises follow the local electrical codes and regulations.

- Weather resistance – consider how the ball clevises withstand the diverse weather conditions.

- Costs – compare the costs of ball clevises from different manufacturers or suppliers available. Assess the availability of ball clevises from local suppliers and import options.

- Safety features – compare safety features including locking mechanisms and cotter pins. This is to ensure they provide secure connections in electrical systems.

- Maintenance requirements – analyze how easy it is to inspect and maintain different ball clevises designs. Consider whether ball clevises are able to reduce maintenance requirements.

Certifications and standards in South America

There are various certifications and standards that govern the use of ball clevis in South America. They help ensure the safety and reliability of overhead electrical transmission systems. these standards vary depending by country while some adapt to international standards. The following are the standards and certifications governing the use of ball clevis in South America.

- IEC standards – these are international standards related to electrical equipment and components like ball clevis.

- ISO standards – these standards relate to materials, manufacturing processes and quality management for the ball clevis.

- National electrical codes – each country has their own regulations for the design, installation and maintenance of ball clevises.

- Local regulatory authorities – each country has different authorities responsible for electrical safety and standards.

- ASTM standards – these are for materials, testing methods and dimensions for components such as fasteners, bolts and steel used in ball clevises construction.

Regional market for ball clevis in South America

There are various factors and trends that influence the regional market for ball clevises in South America. Additionally, it is advisable for manufacturers to observe these trends closely for success. The following are the factors influencing the regional market in South America.

- Market competition – multiple manufacturers and suppliers lead to competitive pricing and product diversity.

- International trade – international trade agreements and tariffs affect the pricing and availability of these products.

- Energy sector – policy and regulatory changes in the energy sector influences the investments in electrical infrastructure.

- Technological advancements – innovations in the design and material may influence the purchasing decisions in the market.

- Infrastructure development – the rapid infrastructure development and electrification projects drives the demand for ball clevises.

- Environmental conditions – high humidity in coastal regions influence the choice of materials and coatings for ball clevises.

Frequently asked questions

A ball clevis is a hardware component used in overhead electrical transmission and distribution systems. it helps to provide secure and flexible attachment points for insulators, conductors and other equipment on utility poles.

Ball clevises are available in various types and designs such as standards clevises, tension clevises, swivel clevises among others. Each type and design are suited for a specific application and load requirement.

Regular inspections and maintenance involves cleaning, checking for corrosion, verifying hardware integrity and ensuring the articulation function remains effective.