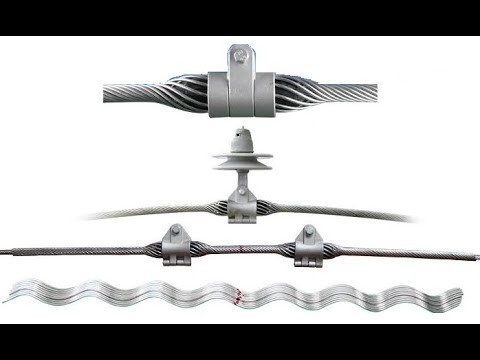

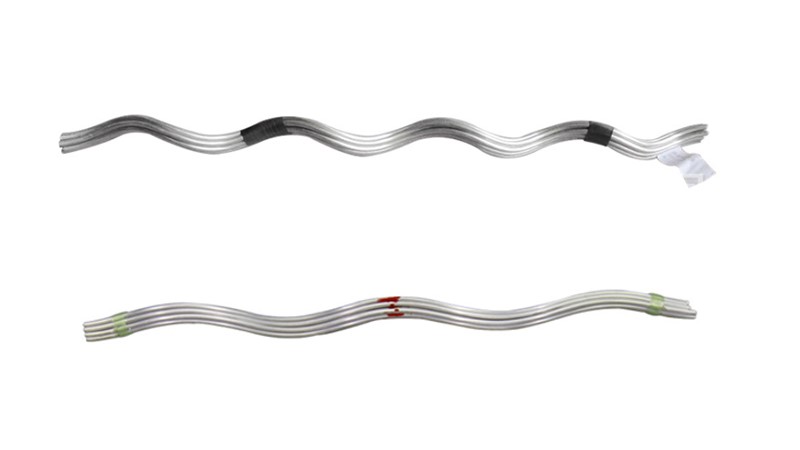

Armor rod play a vital role in overhead transmission lines in protecting the conductors from damage. armor rods take the helical shape that helps in the installation of various conductors. They are from materials such as aluminum alloy or galvanized steel. These materials help to prevent corrosion and increase the lifespan of the application equipment. The primary purpose of the armor rod is to enhance durability and protect from mechanical stress. It has various features such as curved profile, strength restoration and cost effectiveness. Armor rods ensures the safety, reliability and efficiency of overhead power transmission.

Advancements in raw materials for armor rod

The specific raw materials of armor rods depend on the type of conductor they are to protect. It also depends on the specific conductor type and the type of the intended function of the armor rod. Common materials for armor rods include aluminum alloy, galvanized steel and aluminum clad steel. the selected material for armor rod should be like that of the conductor to prevent abrasion. The following are the improvements in armor rod material.

- Nanocomposites – this new material has enhanced strength and durability. It leads to better protection against stress and fatigue. They also offer lighter armor rods that help reduce the weight of the transmission lines.

- Smart coatings – use of sensors and communication technology into the coating enables real-time monitoring of their condition. They also allow predictive maintenance which allows for targeted repairs and replacements.

- Self-healing polymers – use of self-healing polymers within the armor rod materials allows for repairs of small cracks. Such materials also enhance the armor rods resistance to harsh weather conditions.

- Eco-friendly materials – these include materials such as spider silk or nacre. They provide enhanced strength, flexibility and self-healing abilities. Eco-friendly materials offer potential for more sustainable armor rod solutions.

Factors influencing material selection for armor rod

Selection of armor rod material depends on various factors. The selected material should aim to provide effectiveness and suitability of the materials. Careful consideration of the factors ensures the armor rods protect the transmission lines. additionally, it is advisable to consult with industry professionals for guidance on the best material to select from. The following are the factors that influence the decision-making process based on the material.

- Innovation – use of new technologies such as nanocomposites and smart coatings provide armor rods with enhanced strength and monitoring capabilities.

- Sustainability – consider the impact of the materials extraction, production and disposal of the armor rods. Select materials that are eco-friendly for increased sustainability.

- Ease of installation – select armor rods that are easy to work with like aluminum alloy. Consider the cost of installation and maintenance of the armor rods before selection.

- Mechanical stress – select the armor rod that offers strength and flexibility. The materials should withstand stresses such as bending, compression and abrasion.

- Environmental conditions – assess the weather conditions of the armor rod installation area. The selected material should resist corrosion and potential exposure to chemical contaminants.

- Conductor material – the selected rod should be compatible with the conductor material. This is to help prevent abrasion and galvanic corrosion.

Industry advancements and innovation for armor rod

There are various industry standards set to revolutionize the electrical industry through the use of armor rods. These advancements offer greater safety, reliability and efficiency to power grids. They also offer increased strength, intelligence and environmental considerations. These trends ensure the brighter and sustainable future of electrical systems. The following are the various trends and advancements for armor rods.

- Recycled materials – use of old materials like recycled aluminum or steel helps reduce environmental impact.

- Design – advanced computer simulations help in designing armor rods to provide perfect fits to the conductor. This provides most protection while reducing stress points for the rods.

- Anti-vibration dampers – use of built-in dampening mechanisms within the rod helps to reduce vibration and fatigue stress. This also helps to increase the lifespan of the armor rod.

- Anti-icing coatings – coatings with ice-repellent properties reduce power outages caused by ice buildup on lines. This also helps to reduce maintenance costs and activities.

- Robotic installation – use of robots during installation enhance safety, increase efficiency and promote remote operations. Thes could include aerial robots, climbing robots and ground-based robots.

- Advanced crimping materials – this includes use of self-locking crimp sleeves and automated & smart crimping. This could hep to reduce the risk of human error and ensure reliable protection for the line.

Technical specifications for armor rods

Armor rods are available in various designs, types, sizes and shapes that provide specific benefits. Checking the technical specifications for armor rods helps to protect your application. It also helps to ensure reliability and safety. Additionally, it is advisable to consult industry professionals for guidance on the specifications that suit your application. The following are the key factors that influence the technical specifications of armor rods.

- Compatibility – check the conductor type and diameter and ensure the selected armor rod fits . This helps to prevent abrasion and slipping.

- Design – check the design, color coding and ease of crimping the armor rod offers. This helps to ensure faster ease of installation and enhance compatibility with the armor rod.

- Temperature range – ensure the armor rod material can withstand the expected temperature range.

- Material specifications – check the specific material used for the armor rod. This helps to ensure suitability for your application.

- Function – understand the specific function of the armor rod before selection. Choose armor rods that offer strength, fatigue resistance and flashover prevention.

| model | suitable wire | outside diameter(mm) | clamp length(mm) | diameter(mm) | clamp weight(kg) |

| HL-95/15 | LGJ-95/15 | 13.61 | 1400 | 3.5 | 0.7 |

| HL-95/20 | LGJ-95/20 | 13.87 | 1400 | 3.5 | 0.7 |

| HL-97/55 | LGJ-95/55 | 16.00 | 1500 | 3.5 | 1.0 |

| HL-120/7 | LGJ-120/7 | 14.50 | 1400 | 3.5 | 0.7 |

| HL-120/20 | LGJ-120/20 | 15.07 | 1400 | 3.5 | 0.7 |

| HL-120/25 | LGJ-120/25 | 15.74 | 1400 | 3.5 | 0.7 |

| HL-120/70 | LGJ-120/70 | 18.00 | 1800 | 4.5 | 1.3 |

| HL-150/8 | LGJ-150/20 | 16.00 | 1500 | 3.5 | 1.0 |

| HL-150/20 | LGJ-15020 | 16.67 | 1500 | 3.5 | 1.0 |

Supplier and vendor information in the market

Finding the right supplier in the market might be a tough nut to crack. The right selection helps to ensure the quality and reliability of the overhead transmission lines. there are various resources in the market that helps to find the right suppliers depending on your application needs. Additionally, it is advisable to check with trade associations, industry publications, online marketplaces, regional and local distributors and manufacturer websites. The following are the tips to help find the right supplier or vendor.

- Prices and specification – compare prices from different suppliers. Compare their offerings based on factors like material, strength and design.

- Supplier reputation – check for suppliers with a proven track record and experience in your specific region.

- Customer reviews – check the online reviews and industry recommendations to gain insights into the quality and service of different suppliers.

- Certifications and standards – ensure the selected armor rods follow the relevant industry standards and certifications. This helps to ensure the quality and safety of the armor rods and the application.

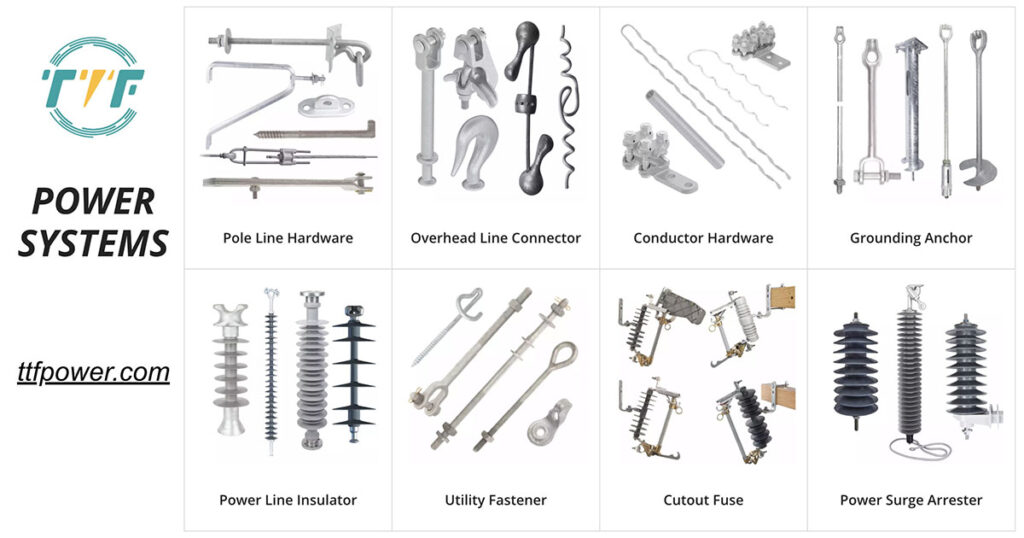

Armor rods are available in a variety of materials, sizes, and features from TTF Power Systems. They have an extensive product line, affordable prices, and global reach. Their armor rods come in a variety of shapes, sizes, kinds, and unique characteristics. TTF Power Systems guarantees quality and dependability because of their vast experience in the power line sector. Their contact details are as follows.

Website: https://ttfpower.com/

Catalog: https://ttfpower.com/about-us/

Landline (M-F, 9 am-6 pm): (+86) 22-8523-3528

Customer Service: support@ttfpower.com

Community forums and expert interactions for armor rods

Online communities for armor rods help to find the right information and guidance needed to ensure safety and protection. Some may include expert interactions that offer professional help to the use of armor rods. Additionally, it is advisable to be active and ask the right questions in the communities to gain better understanding. It is also advisable to check the right information on manufacturers websites to be sure. The following are the various community forums and expert interactions platforms for armor rods.

- Reddit – this is an engineering forum that offers spaces for professional and enthusiasts to discuss technical challenges and solutions. It helps to ask questions, share experiences and learn from the knowledge of engineers and technicians.

- The Overhead Lines Working Group – this is an industry specific forum that provides a platform for experts in overhead line technology to discuss best practices. They also help to share new developments and challenges related to armor rods.

- Transmission and distribution communities – this is an online community that offers spaces for professionals in the power transmission and distribution industry. They share knowledge and experiences about use of armor rods.

- Manufacturer and supplier websites – this 2help to understand the technical specifications and resources of armor rods. They may provide white papers, application guides and contact information of technical support.

- Academic publications – check research papers and articles published to gain knowledge on the technical aspects of armor rod technology.

Frequently asked questions

An armor rod is a component used to protect conductors on overhead transmission lines. They are from materials such as aluminum alloy, steel or composite materials that offer strength and durability.

There is development of new innovations that help increase safety and reliability of overhead transmission lines. These include materials, smart guards, design change and increased sustainability.

Common materials used in the installation of armor rods include crimping tools, wrenches, cleaning tools, measuring tapes and personal protective equipment.