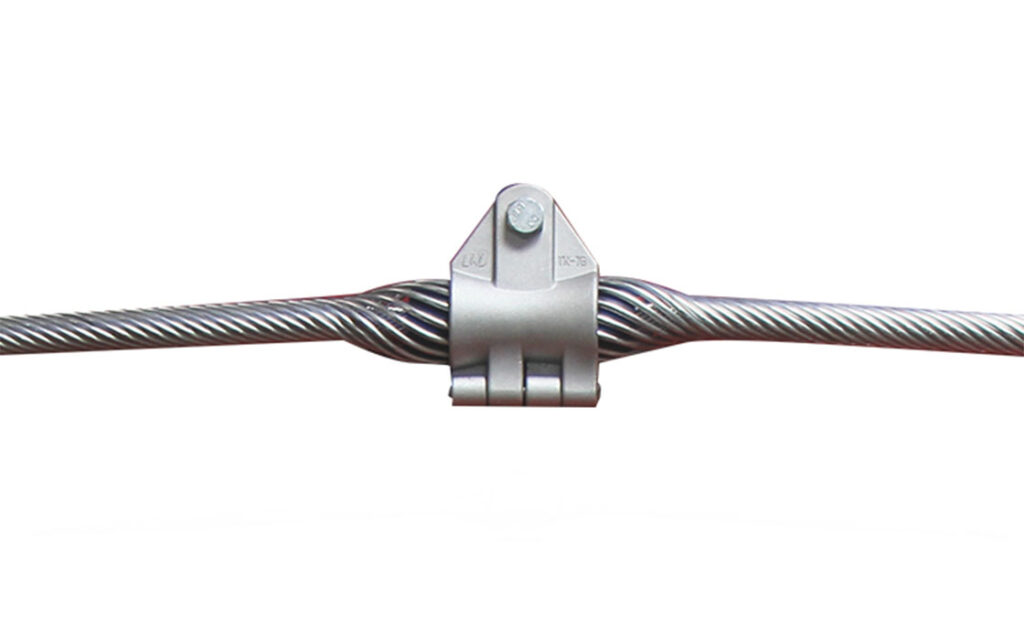

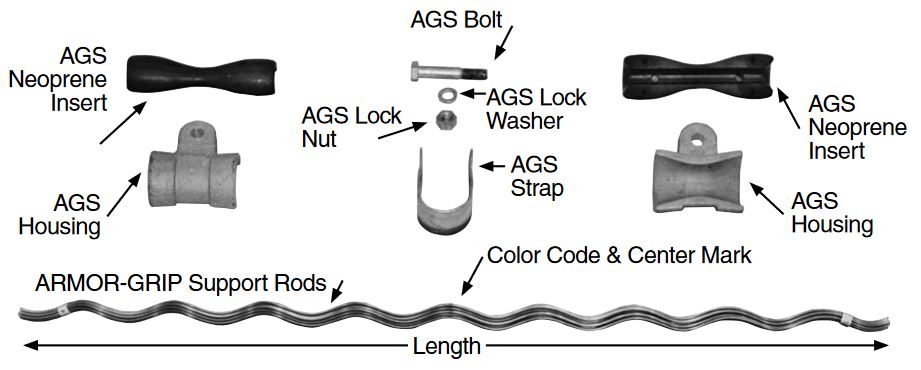

An armor grip suspension is a type of hardware used on the overhead power line systems. it is also known as a preformed suspension clamp or AGS suspension clamp. Its design provides support and strain relief for cables. Armor rods help to maintain the proper sag and tension of the cables. Their main function is to provide mechanical support and tension to the conductor. They also protect them from environmental conditions, mechanical support and reduce the risk of damage. It installs by attaching the suspension clamp to the supporting structure like pole or tower. Armor grip suspension is from materials such as aluminum or steel to withstand the mechanical stresses. They help to reduce the stress and strain on the cables and ensure stability and durability. The hardware is hot dip galvanized that makes them resistant to rust and corrosion for durability.

Types and components of armor grip suspension

Armor grip suspensions are available in various types and designs. Each type has designs to fit specific applications and load requirements. They also work with various components such as grips, rods, clamps and other supporting elements. The following are the common types of armor grip suspension.

- Single grip suspension – this is the most basic design of the suspension. It features a preformed metal rod that wraps around the conductor. The single grip is suitable for smaller conductors and lower load requirements.

- Double grip suspension – this one feature two preformed rods that sandwich the conductor for increased stability. It mainly works for larger conductors, higher tensions and angles. It offers vibration damping and fatigue resistance.

- Fork-type suspension – this one has a forked design for larger conductors to provide extra support and reduce rotation.

- Oval-shaped suspension – this is ideal for bundled conductors offering uniform pressure distribution.

- Ground wire type – this has a design for anchoring overhead ground wires with enhanced vibration dampening.

- Aluminum suspension – this material provides a light weight option for long spans in need for weight reduction.

- Galvanized steel suspensions – these suspensions are most common and offer good corrosion resistance for standard environments.

Materials and properties for armor grip suspension

Armor grip suspension is from various materials that help them provide resistance, strength and durability. They also play a part in their performance, longevity and suitability for different applications. selecting the best materials helps you to balance cost, performance and long-term benefits. Additionally, it is advisable to consult with manufacturers and engineers for guidance on the best materials and properties. The following are the common materials and properties for armor grip suspensions.

- Galvanized steel – this is the most common material for armor grip suspension. It offers good strength and stiffness mainly for smaller conductors. It offers corrosion resistance and may not be suitable for high tension conditions.

- Aluminum – suspensions from this material are ideal for long spans or situations where weight reduction is crucial. It also has good conductivity good for applications like grounding. Aluminum has lower corrosion resistance and it therefore needs extra protection in harsh environments. It also higher in cost compared to steel.

- Composite materials – this one offer properties such as high strength, stiffness and corrosion resistance. It is lighter than steel which helps to maintain the strength. Composite materials help to reduce fatigue and improves conductor lifespan.

- Coatings – specialized coatings apply to any material and help to increase corrosion resistance in harsh environments. The various options include Epoxy, Zinc and polytetrafluoroethylene (PTFE).

Technical specifications and datasheets for armor grip suspension

Technical specifications and datasheets for armor grip suspensions help to make informed decisions. It helps to ensure compatibility with your project requirements for safe and reliable power line applications. This information may be available on manufacturers websites, industry databases, trade publications and direct contact with manufacturers. Here are some tips for finding specific technical information for armor grip suspension.

- Know the exact model’s name and series which helps narrow down the research.

- Identify the conductor size, load capacity, material, design type and extra features.

- Combine specific model names, technical terms and application requirements.

- Contact manufacturers for the most accurate and up to-date information for your needs.

Technical specifications

| Cat. No. | Applicable conductor | Dimensions (mm) | Matching gold |

| NL-70-70/10 | JL/G1A-50/8 | 670 | QXH-0748 |

| NL-70-50/9 | JL/G1A-70/10 | 720 | QXH-0748 |

| NL-70-95/15 | JL/G1A-95/15 | 860 | QXH-0748 |

| NL-70-95/20 | JL/G1A-95/20 | 860 | QXH-0748 |

| Nl-70-120/20 | JL/G1A-120/20 | 870 | QXH-0748 |

| NL-70-150/20, | JL/G1A-150/20 | 1000 | QXH-0748 |

| NL-70-150-25 | JL/G1A-130/25 | 1000 | QXH-0748 |

Maintenance best practices for armor grip suspension

Regular maintenance and inspection of armor grip suspension helps to ensure the continued reliability and performance. It helps to ensure the armor grip suspension remains in best conditions to contribute to efficiency and reliability. Additionally, it helps to identify and address potential issues that could lead to failures and accidents. The following is a basic guide for the maintenance and inspection of the armor grip suspension.

- Conduct routine inspections of the armor grip suspension components. Check for signs of wear, corrosion or damage.

- Confirm the alignment of the armor grip suspension to prevent uneven stress distribution and performance of the suspension clamp.

- Ensure the cable tension is within the recommended range where excessive sagging compromises the integrity.

- Inspect the attachment points of the armor grip suspension to the supporting structures. Ensure the hardware components are securely in place and tight to the specified levels.

- Check for signs of corrosion on the suspension clamp and other hardware. Address any identified corrosion as needed.

- Assess the impact of wind-induced vibrations to help mitigate the effects of galloping.

- Inspect midspans to ensure they provide adequate support and prevent excessive sagging.

- Consider periodic lubrication of moving parts to reduce friction and enhance longevity.

- Replace any damaged components, tighten loose bolts and make necessary adjustments for reliability.

- Maintain detailed records of inspection findings and adjustments made. This is to keep track of the condition of the armor grip suspension.

Industry updates and advancements

The industry is constantly growing and evolving with innovative technologies that boost performance. They also help to enhance efficiency and expand application possibilities. These advancements also have the capacity to revolutionize power line infrastructure. They would make it more reliable, efficient and sustainable for the future. Additionally, their adoption varies depending on region, manufacturer and regulatory landscape. The following are the common updates and advancements for armor grip suspensions.

- Enhanced materials and design – this include advanced composites, bio-based materials and optimized design algorithms. These advancements provide higher strength, lower weight and develop more efficientand stress resistant suspension designs.

- Integrated technologies and smart features – use of smart technologies such as sensor integration, data analytics and AI and self-healing materials. They help with real-time monitoring of conductor tension, vibration and environmental conditions. They also enhance predictive maintenance, fault detection and line performance optimization.

- Adaptability – the use of armor grip suspension may expand to various application sin the industry. These include underground power lines, renewable energy integration and aesthetic integration.

- Sustainability – armor grip suspension may also help in the environmental focus and sustainability. This is through recycling, reduced environmental impact and lifespan extension.

- Regulatory standardization – there are various standards that govern the use of armor grip suspensions. Advancements may lead to developing industry standards, regulatory alignment and certification programs. These help to ensure quality, design, testing and performance of armor grip suspension. Regulations also help to ensure compatibility with existing safety regulations and environmental standards.

Frequently asked questions

Most armor grip suspension designs work with common conductor materials like ACSR and AAC. Compatibility with specialized materials like aluminum alloy conductors require specific models.

Load capacities varies depending on the design, conductor size and material. It is advisable to consult with manufacturers for specific calculations.

Improper installation can compromise performance and lead to conductor damage. Always follow recommended procedures and use qualified personnel.

Various factors such as conductor size, design type, extra features, quantity and manufacturer may influence the costs of the armor grip suspensions.