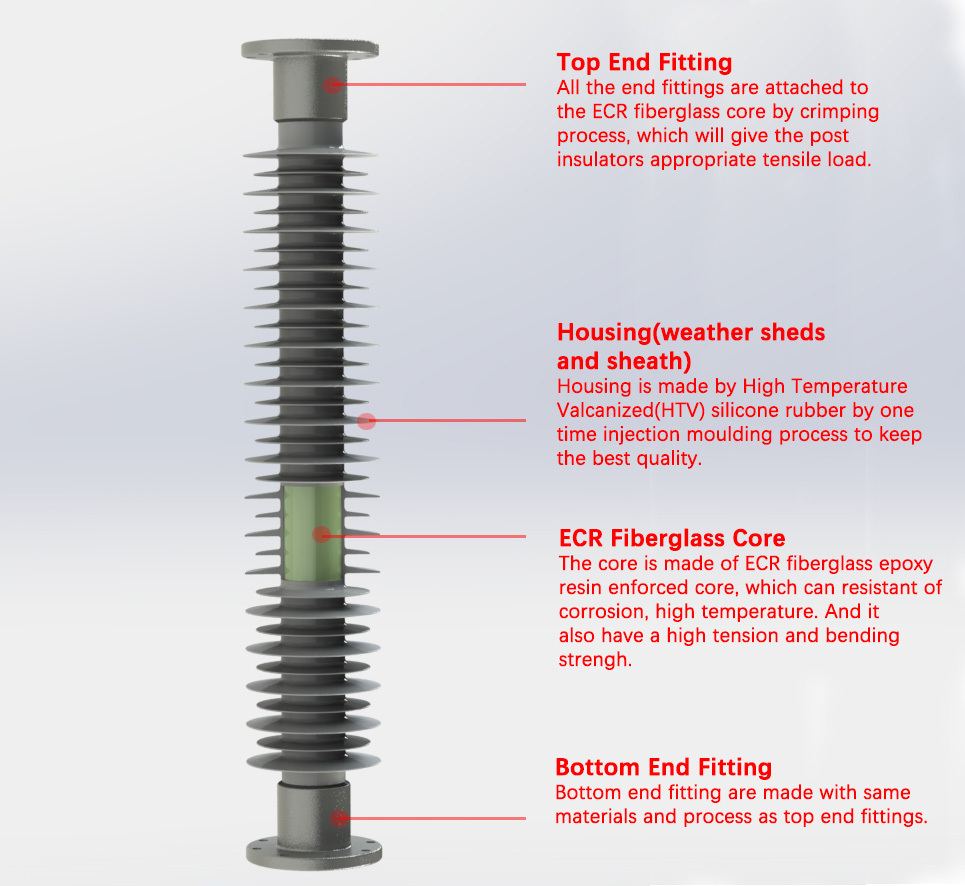

A post insulator is a device used to support and insulate electrical conductors. from grounded structures. It is also known as a stand-off insulator. They are cylindrical insulating structures with a central hole or groove. This hole is for securing the conductor. They are from materials such as porcelain, glass or composite materials. These materials are particularly helpful in the tropical and diverse climates of Southeast Asia. They help by resisting salt spray in the coastal areas and the humid climate of these regions. The common types of post insulators include solid-core, cap and pin, stacking and station post insulators. They find use in applications such as transformers, arresters, substations, transmission lines and railway electrification.

Key features of the post insulator

Post insulators have several features that increase their safety and reliability. They also provide electrical insulation and mechanical support to the application. Additionally, their features ensure their effectiveness and reliability in various applications. They also make the post insulator a versatile and dependable component. This is for use in a wide range of electrical and industrial applications. the following are the key features of a post insulator.

- Insulating material – they are from high quality materials that resists rust, corrosion and electrical insulation. The choice of the material depends on voltage rating and environmental conditions.

- Voltage rating – they are available in various voltage ratings for various electrical systems. They work in low voltage, high voltage and extra high voltage transmission lines.

- Design – some of the common designs for post insulators include solid-core, multi-part, cap and pin and stacking insulators.

- Mechanical strength – the insulators withstand loads and stresses. This ensures their ability to support electrical components and equipment safely.

- Environmental durability – the designs also enable them to withstand harsh environmental conditions. This is including UV radiation, humidity and temperature variations.

- Ease of installation – they installation is straightforward which facilitates efficient setup.

- High creepage and clearance distances – they provide adequate creepage and clearance distances. This is to prevent electrical flashovers and ensure proper insulation.

Selection and installation of post insulator

The selection process is a vital process that requires careful considerations of various factors. These factors ensure their effectiveness and reliability in a specific application. These factors include voltage rating, mechanical load, design, resistance, cost and compliance with standards. The installation of post insulators should ensure their proper function and long-term durability. Additionally, it is advisable to consult with industry experts for guidance on the installation process. The following is a basic installation guide of post insulators.

- Safety precautions – ensure you follow the appropriate safety procedures. This is including the use of personal protective equipment.

- Inspection of insulators – inspect the post insulators for any visible defects or damage. This is any damage that may have occurred during transport or handling.

- Surface preparation – prepare the surfaces of installation and ensure they are clean, dry and free from any contaminants.

- Positioning and alignment – position the post insulators according to the installation design and requirements.

- Mounting hardware – ensure the mounting hardware such as threaded studs are securely fastened to both the insulator and the supporting structure.

- Torque specification – tighten the mounting hardware to the manufacturer’s recommended torque specifications.

- Fasteners – use washers and nuts to secure the insulator to the mounting hardware. This is through following the manufacturer’s instructions.

- Electrical connections – ensure that all connections are secure and under electrical safety guidelines.

- Sealing and weatherproofing – apply suitable sealing and weatherproofing materials such as silicone sealants. This is to prevent moisture ingress and ensures the insulators long-term performance.

- Grounding – grounding is necessary to dissipate electrical charges.

- Final inspection – conduct a visual inspection of the installed post insulators. This helps to verify that they are correctly aligned, mounted and free from any defects.

- Documentation – keep detailed records of the installation process. This is including torque values, assembly procedures and any relevant test results.

Maintenance and inspection of post insulators

Post insulators requires regular inspection and maintenance to ensure their long-term reliability and effectiveness. It also helps identify and address issues before they lead to insulator failure or electrical system problems. Also, it is advisable to consult with the manufacturer for guidance on maintenance and replacement. The following is a basic guide to maintenance and inspection of post insulators in Southeast Asia.

- Perform regular visual inspections of post insulators to check for any visible signs of damage, wear or contamination.

- Check for contaminations such as dirt, dust, pollution deposits or salt buildup on the insulator surface.

- Clean the contaminated post insulators as needed using a soft brush, cloth or non-abrasive cleaning material.

- Inspect for signs of electrical flashovers which may leave carbon or scorch marks on the surface.

- Check for any visible mechanical damage such as cracks, chips or breakage. This can compromise the insulators structural integrity and electrical insulation properties.

- Inspect for any evidence of corona discharge which can lead to partial discharge activity. Look for signs of ozone odor, UV light emissions or partial discharge marks on the surface.

- Examine the mounting hardware for tightness and signs of corrosion or wear.

- Ensure the creepage paths on the insulator surface are clear and free from any obstructions.

- Keep detailed records of all inspections, maintenance activities and any issues identified. This helps to keep track of the post insulators.

Comparative analysis of post insulators in Southeast Asia

Conducting a comparative analysis for post insulators includes assessing various factors. This may include types, materials, manufacturers, market trends and regional considerations. The comparative analysis also provides a well-rounded view of the market landscape, trends, challenges and opportunities. Additionally, the analysis is valuable for manufacturers, suppliers and decision-making in electrical industry in Southeast Asia. The following are the key factors included in the comparative analysis.

- Type of insulator – identify the types of insulators available in the market and analyze the popularity and use cases of each type.

- Material – examine the materials used in the region and assess the advantages of each material in local applications.

- Voltage rating – determine the most common voltage classes based on the region’s electrical infrastructure.

- Market trends – analyze the market trends in the region. These include the adoption of pollution-resistant insulators.

- Regional variations – recognize the diverse countries and the varying infrastructure needs. It may also include the environmental challenges.

- Compliance – ensure the selected post insulator adheres to the local and international standards and regulations.

- Market challenges – investigate the challenges faced by post insulator market in the region. These include budget constraints, supply chain issues and competition from international manufacturers.

Certifications and standards for post insulator in Southeast Asia

Certifications and standards in Southeast Asia ensure the quality, safety and performance of post insulators. The compliance helps the manufacturers, suppliers and users to maintain consistency and reliability in electrical systems. the following are the common standards for post insulators in Southeast Asia.

- IEC standards – this provide guidelines for the selection and dimensioning of high-voltage insulators.

- ISO certification – manufacturers may obtain ISO certifications to demonstrate their commitment to quality and environmental responsibility.

- Pollution performance standards – insulators should comply with the pollution performance standards. This includes salt-fog tests and pollution flashover tests.

Regional and national standards – the various countries have their own national or regional standards for post insulators.

Regional market for post insulator in Southeast Asia

There are various factors that influence the regional market for post insulators in Southeast Asia. The manufacturers and suppliers in the region need to stay attuned to these factors since the market is volatile. This is to effectively serve the diverse needs of Southeast Asian countries. The following are the common factors that influence the market for pos insulators.

- Market size and growth – the ongoing infrastructure development and electrification projects leads to increased demand for electricity and power distribution.

- High-voltage application – there is increasing demand for high-voltage post insulators. This is in areas where transmission and distribution networks require higher voltage support.

- Environmental conditions – some of the areas experience high pollution levels, humidity and coastal exposure. This influences the demand for pollution-resistant and environmentally friendly post insulators.

- Pollution-prone areas – industrial activities and natural factors lead to pollution in some parts of Southeast Asia. This leads to the demand for pollution-resistant insulators for these areas.

- Competition – the market for post insulators is competitive with both domestic and international manufacturers supplying products to meet the regions demands.

- Smart grids – the deployment of smart grid technologies and distribution automation systems in certain countries may require specialized post insulators.

Frequently asked questions

Post insulators are devices used to support and insulate electrical conductors and equipment. They find use in applications such as substations, transformers, overhead transmission lines and railway electrification across Southeast Asia.

The post insulators require regular visual inspections, cleaning and adherence to maintenance schedules. This helps to ensure longevity and reliability of post insulators in Southeast Asia.

Post insulators maintain electrical safety and reliability by providing insulation and support for critical electrical components and conductors in various applications.