Forged eye bolts are types of fastener used for lifting, rigging and anchoring applications. The eye of the bolt is a circular loop that provides a secure attachment point for ropes, cables, chains or hooks. It manufactures through a forging process where a metal blank heats and shapes using compressive force. It also has a threaded shank that allows the eye bolt to screw into a compatible threaded hole or component. A forged eye bolt is from materials like carbon steel or alloy steel. These materials secure strength, durability and load-carrying capacity. They mostly work in applications such as construction, manufacturing, maritime and transportation.

Components of the eye bolt

The forged eye bolt has several components working together to provide reliable and efficient lifting. The available components vary depending on the type of eye bolt and the application to use in. Other components of the forged eye bolt include corrosion protection, finish and markings. The main components of the forged eye bolt are as discussed below.

- Eye – this is the circular loop at one end that serves as the attachment point for ropes, cables, hooks or other lifting equipment.

- Shank – the shank is the straight, threaded part of the eye bolt extending from the eye. It allows the bolt to screw into a compatible threaded hole.

- Threaded end – the threaded end of the shank is the part that contains the threads. It enables the eye bolt to be securely fastened and attached to the other components.

- Threaded length – this is the portion of the shank that contains the threads to determine how far the eye bolt can screw into a threaded hole.

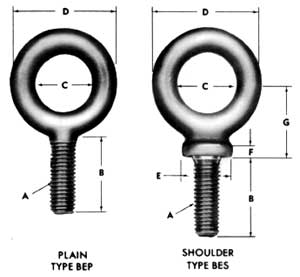

- Shoulder – this is the part between the eye and the threaded shank that provide a larger bearing surface. This helps distribute the load more evenly.

Types of forged eye bolt

Forged eye bolts have many designs and configurations. Each designed for specific lifting, rigging or anchoring applications. The selected type of bolt depends on the load capacity, application environment and specific needs of lifting or rigging task. Also, ensure the selected forged eye bolt meets relevant safety standards and guidelines for the intended application. The following are the common types of the forged eye bolt.

- Regular forged eye bolt – this is the standard type of the forged eye bolt. It works in general lifting, rigging and anchoring purposes.

- Collar forged eye bolt – a collar bolt features a collar or flange around the threaded shank. This is to provide extra support and stability when the eye bolt attaches to the surface.

- Shoulder forged eye bolt – this eye bolt has an extended part between the eye and the threaded shank. This helps to distribute the load more evenly to reduce stress concentrations on the attachment point.

- Swivel forged eye bolt – these bolts have a swiveling mechanism that allows the eye to rotate independently from the threaded shank to prevent twisting or tangling of ropes.

- Shoulder swivel forged eye bolt – this type combines the benefits of a shoulder eye bolt and swivel eye bolt. This helps to offer both load distribution and free rotation of the eye.

- Metric forged eye bolt – these types have a design that matches the metric thread sizes. They help to provide compatibility with metric bolts.

- Rotating forged eye bolt – the rotating forged eye bolt can swivel 360 degrees. This allows the eye to rotate freely in all directions.

- Lag thread forged eye bolt – lag thread forged eye bolt have a lag screw thread at the end of the shank. This shank allows them to screw directly into wood.

Application areas of eye bolt

Forged eye bolts find use in various applications in the industry due to their reliability and versatility. They play a vital role in providing safe and reliable lifting, rigging and anchoring solutions. The selected forged eye bolt should ensure their performance and safety in various applications. The following are the common application areas of the forged eye bolts.

- Construction – the forged eye bolts help in lifting and anchoring heavy construction materials such as steel beams, concrete forms and prefabricated components.

- Maritime – forged eye bolts work in marine and offshore industries to lift and secure equipment, cargo and rigging on ships, boats and offshore platforms.

- Industrial manufacturing – forged eye bolts help in lifting and positioning machinery, molds and tooling.

- Oil and gas industries – the bolts also help in rigging and lifting heavy machinery and securing components in the oil rigs and refineries.

- Transportation – the bolts work in logistics and transportation for securing cargo during shipping and handling.

- Telecommunications – forged eye bolts help in lifting and positioning utility poles and communication towers.

- Entertainment – forged eye bolts help in rigging lighting, sound equipment and scenic elements in theaters and event venues.

- Fall protection – they also help in fall protection systems by creating anchor points for safety lifelines.

Installation guide for forged eye bolt

The installation of the forged eye bolt involves securely attaching it to a surface. This creates a reliable anchor point for lifting, rigging or anchoring operations. Some manufacturers offer installation guidance for the specific forged eye bolt model. Additionally, ensure the installation process aligns with industry best practices and relevant safety guidelines for the application. The following are the steps involved in installation process for forged eye bolts.

- Choose the suitable location for installing the forged eye bolt to ensure that the surface can support the intended load.

- Prepare the surface by cleaning and ensure it is free from any obstructions that could interfere with installation and performance.

- Screw the forged eye bolt onto the threaded rod with the matching thread size. Tighten it using hands and ensure the eye bolt is comfy at the surface.

- Add washers or nuts to the threaded rod or bolt to create the desired spacing. This also helps distribute the load and improve stability.

- Ensure that the eye of the forged eye bolt positions in the desired direction using a level to make sure it install correctly.

- Tighten the forged eye bolt onto the threaded rod and apply even pressure to achieve a secure and stable connection.

- Conduct a test to ensure the forged eye bolt is securely attached and can withstand the intended load.

- Conduct periodic inspections to ensure the installation remains in good condition.

Selecting the best forged eye bolt

Selecting the forged eye bolt involves considering various factors. The selected forged eye bolt should ensure safety, reliability and optimal performance. Additionally, follow the manufacturers’ guidelines and safety recommendations when using forged eye bolts. The following are the key factors to consider when selecting forged eye bolts.

- Consider the overall budget of the forged eye bolt and balance the quality and performance of the component.

- Consider the specific environment the eye bolt will install and consider temperature, humidity, exposure to chemicals or corrosive substances and outdoor conditions.

- Evaluate the installation process for the chosen forged eye bolt.

- Consider the shape and size of the forged eye bolt and choose a type that that holds the type of attachment method.

- Determine the greatest load needed to support. Choose a forged eye bolt with a load rating that exceeds the intended load.

- Ensure the thread size material matches the thread rod or anchor point you will be using.

- Select the suitable material for the forged eye bolt based on the environmental conditions.

- Choose the type and design of the forged eye bolt that best suits your application.

- Ensure the selected forged eye bolt meets the relevant safety standards and specifications.

- Choose from reputable manufacturers known for producing high quality and reliable products.

Frequently asked questions

A forged eye bolt is a type of fastener that has threaded ends and a looped eye used for rigging, lifting and anchoring applications. the loop provides an attachment point for ropes, cables, chains, hooks or other lifting and rigging equipment.

Forged eye bolts offer various benefits in the lifting, rigging and anchoring applications. They include strength and durability, reliable lifting points, load distribution, swiveling capability, corrosion resistance, ease of installation, cost effectiveness, industry approval and customizable options.

Forged eye bolts also have limitations to consider when selecting for your project. These limitations include swiveling limitations, safety factor, regular inspection, installation expertise, thread compatibility and environmental factors. The selected forged eye bolt should ensure safe and reliable forged eye bolt usage.