A no wrench screw anchor is an earth anchor used in the construction and maintenance of overhead transmission lines. It is also known as power screw anchor or a no-torque screw anchor. The anchor has designs that help them to provide a secure and stable foundation for utility poles or other equipment. It has a helical design that screws into the ground without need for a wrench or tightening tools. It provides versatility, durability and ease of installation. No wrench screw anchors provide secure foundations for utility poles. This helps to ensure the uninterrupted power transmission to remote villages in South America. Examples include single-threaded screw anchors, multithreaded screw anchors, helical piers, guy anchors and round shaft screw anchors. They find use in applications such as anchoring utility poles, guying structures, grounding systems, telecommunication lines and foundation for temporary structure.

Key features of no wrench screw anchor

These features help to ensure the no wrench screw anchors to have the widespread popularity. This is due to their versatility, durability and ease of installation. The following are the key factors of the no wrench screw anchors.

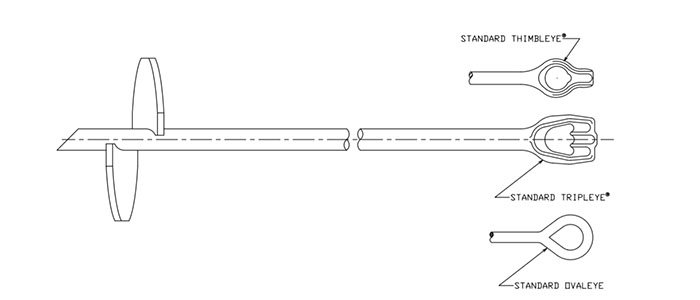

- Helical design – they have a helical design that allows the anchor to screw into the ground without the need for wrench. The helix efficiently penetrates the soil to create a strong and reliable grip as it rotates deeper into the ground.

- Ease of installation – no wrench screw anchors install by turning them directly into the ground. This helps to reduce the labor costs and installation time which makes them a more efficient and cost-effective solution.

- Versatility – they are compatible with a wide range of soil types including loose, compact and rocky soils. They install at various angles to accommodate different pole configurations and terrains. This also makes them adaptable in a wide range of ground conditions.

- Durability – they are from galvanized steel to provide excellent corrosion resistance. This protects the anchor from rust, corrosion and degradation to ensure the longevity. This is especially in areas with high moisture or exposure to chemicals.

- Load bearing capacity – no wrench screw anchors are available in various sizes and configurations. This offers a range of load-bearing capacities to suit different applications.

- Minimal soil disturbance – the anchors reduce soil disturbance as compared to traditional anchors. The helical design allows the anchor to penetrate the soil without causing displacement. This is important to reduce the impact on surrounding vegetation and the environment.

Selection and installation of no-wrench screw anchor

Selecting the best no wrench screw anchor helps to ensure the stability and safety of overhead transmission lines. It involves considering factors such as soil conditions, load requirements, installation ease, cost, corrosion resistance and environmental impact. The installation should ensure the anchors are securely installed and can withstand the intended loads. The following is a general process of the no wrench screw anchor.

- Preparation – collect all the necessary tools required for the installation. This is including extension rod, no wrench screw anchors, levels and safety equipment.

- Site assessment – conduct a thorough assessment of the site before installation. Consider the soil type, load requirements and potential obstacles that affect performance.

- Marking and positioning – mark the exact locations where the screw anchors will install. The positions should align with the design specifications and structural requirements.

- Anchor preparation – inspect the screw anchor to ensure it is in good condition and verify the blades are free from damage.

- Installation process – use the power tool to rotate the screw anchor into the ground. Apply downward pressure while rotating.

- Depth monitoring – monitor the depth of penetration to ensure the screw anchor reaches the desired depth. The anchor should reach proper depth to ensure stability.

- Torque verification – use a torque bar or wrench to verify that the anchor installs with the recommended torque.

- Installation of extra components – attach extra components to the screw anchor such as brackets or hardware.

- Documentation – maintain detailed documentation of the installation process. This is including the depth of installation, torque values and any specific conditions.

Maintenance and inspection of no wrench screw anchors

Proper maintenance and inspection of the anchors help to ensure stability of structures. It also helps to identify and address potential issues that may lead to failures or accidents. The soil conditions in South America affect the frequency of maintenance and inspection. Additionally, it is advisable to perform professional maintenance once in a while for continued performance. The following is a basic guide for the maintenance and inspection in South America.

- Conduct periodic inspections to look for signs of damage, corrosion or unusual wear on the blades and shaft.

- Monitor the surrounding ground for signs of settlement or movement. The uneven settling indicates potential issues with the anchor’s stability.

- Remove any vegetation or debris around the anchor’s performance and may lead to corrosion.

- Perform an annual torque verification to ensure the anchor remains securely in place.

- Check the depth of the screw anchor to ensure it has not shifted and consider re-measuring the anchors depth.

- Assess the structural integrity of the anchor and any connected components and check for signs of rust, corrosion or wear.

- Apply corrosion resistant coatings to the screw anchor to help protect against rust and corrosion.

- Replace any screw anchors that show signs of wear or damage that is beyond repair to maintain the effectiveness.

- Keep detailed records of inspections, maintenance activities and adjustments made to the anchors.

Comparative analysis of no wrench screw anchors in South America

Conducting a comparative analysis involves assessing and evaluating different types of screw anchors in the market. These factors include soil conditions, nature of construction projects, brands and reputation of manufacturers. Additionally, it helps to ensure proper selection of the no screw anchors to ensure proper performance. The following are the key factors to include in a comparative analysis in South America.

- Soil conditions – assess the performance of no wrench screw anchors in various soil conditions in the region.

- Installation efficiency – assess the efficiency of the installation process for the screw anchors.

- Costs – assess the overall installation costs including labor and equipment.

- Versatility – consider the versatility of no wrench screw anchors in different construction projects. check their ability to adapt to various soil conditions and applications.

- Environmental impact – evaluate the environmental impact of no wrench screw anchors which should have minimal soil disturbance.

- Maintenance requirements – assess the long-term stability and maintenance requirements of structures anchored.

- Manufacturer reputation – consider the reputation of manufacturers providing no wrench screw anchors.

Certifications and standards in South America

South America has various certifications and standards that govern the use of no wrench screw anchors. Most of these countries adapt to various international standards for the use of the anchors. Additionally, it is advisable to ensure the selected no wrench screw anchor meets the relevant certifications and standards. The following are the standards and regulations in South America.

- ISO standards – these are standards that provide guidelines for design and installation of helical piles.

- National standards – these are standards in South American countries for construction and anchoring systems.

- Industry associations – these associations work closely with regulatory bodies in South America.

- Local building codes – the anchors comply with local building codes and regulations to set standards for construction to ensure safety and reliability.

- Documentation and traceability – manufacturers should provide detailed documentation about the specifications, installation procedures and performance capabilities.

- Environmental compliance – ensure the materials used in the anchors comply with environmental standards.

Regional market for no wrench screw anchor in South America

There are various factors and trends that influence the regional market for no wrench screw anchors in South America. There are various market dynamics that shape the demand, supply and availability of the screw anchors. Additionally, it is advisable to understand the various conditions and factors that influence the supply in the market. The following are the key factors that influence the regional market in South America.

- Construction industry trends – monitoring trends in the construction industry provides insights into the demand for anchoring solutions.

- Soil conditions – the soil diversity impacts the adoption of different anchoring methods. Their adaptability to various conditions helps increase demand in the market.

- Cost and efficiency – the efficiency and cost effectiveness of installation makes them attractive for construction projects where labor costs are significant.

- Manufacturers – the presence of manufacturers and suppliers of the screw anchors impacts the availability and adoption of the anchors.

- Environmental considerations – construction practices minimize environmental impacts to gain preference.

Frequently asked questions

A no wrench screw anchor is an earth anchor used to provide a secure and stable foundation for utility poles, telecommunication lines and electrical infrastructure. They help to ensure the stability and resistance to strong winds, heavy loads and earthquakes.

No wrench screw anchors are applicable in various soil conditions including sandy soils, compacted soils, rocky soils, expansive soils, wet soils and seismic zones.