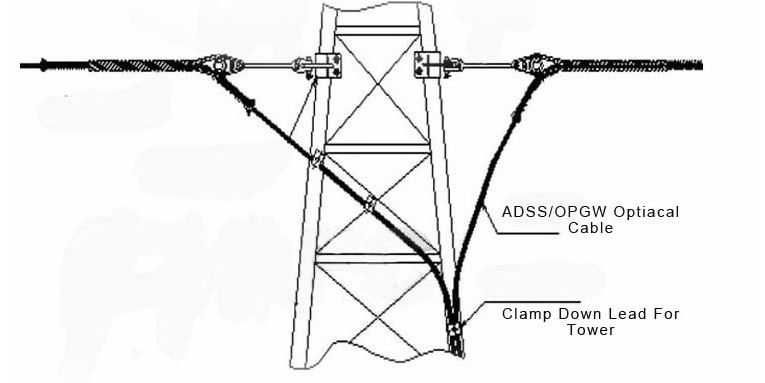

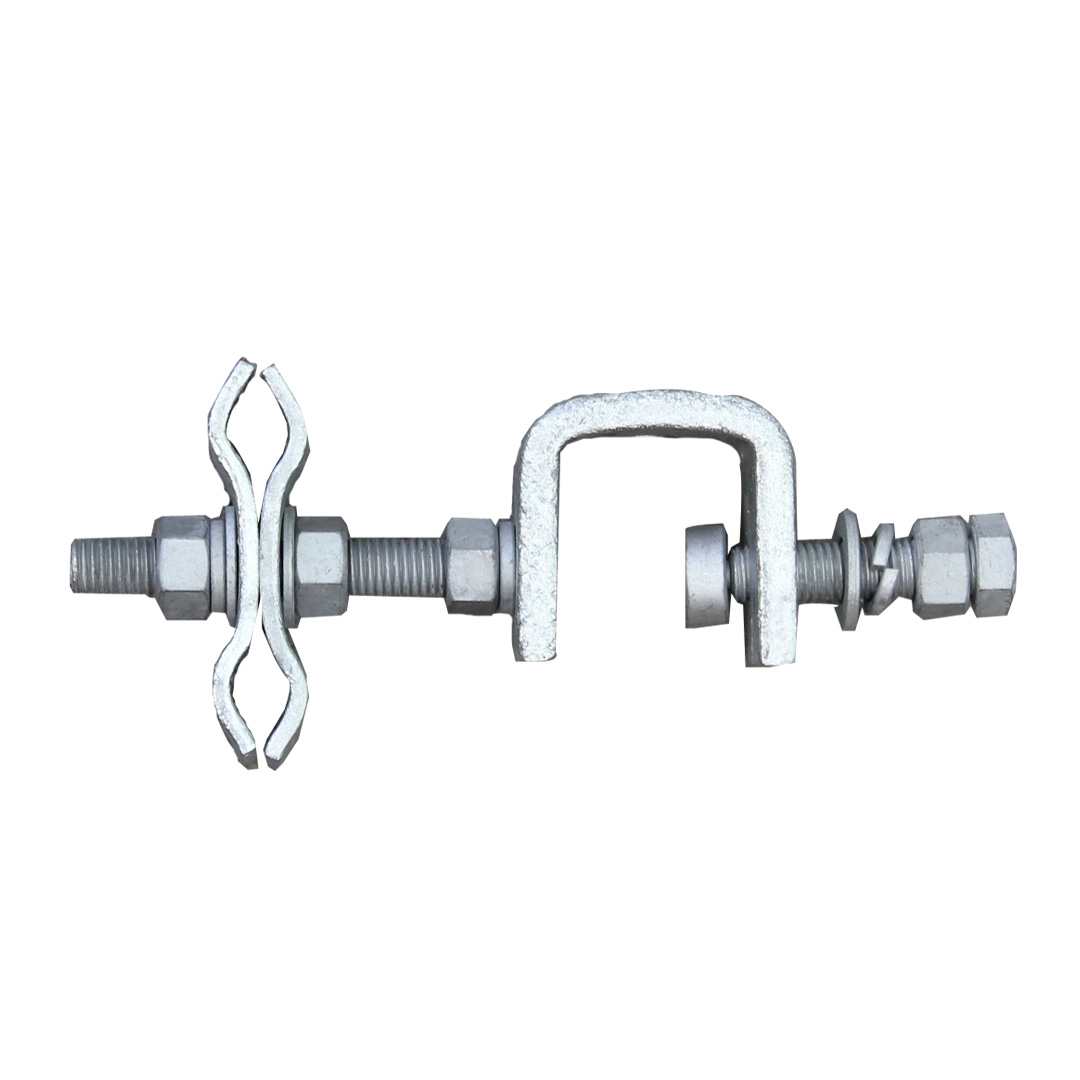

A downlead clamp is a component used to secure and support the downlead cable that connects the overhead line to the ground. The downlead is a cable runs from the overhead line to the ground. This is to ease the safe transfer of electrical power from the overhead transmission line. The downlead clamp plays a crucial role in maintaining the integrity of the downlead connection. It helps to prevent sagging or swinging of the downlead. It is important for both electrical safety and the efficient operation of the transmission system. it is from durable materials that resist rust and corrosion. The downlead clamp helps to withstand weather conditions of South America to ensure a secure and stable connection. Common types include parallel groove clamp, clevis clamp, suspension clamp and bolted clamp. They find use in applications such as grounding systems, electrical substations and telecommunications.

Key features of downlead clamp

Downlead clamps provide a secure and stable connection between the grounding systems. The have various features that help ensure reliability and stability to the overhead systems. The following are the features of the downlead clamps.

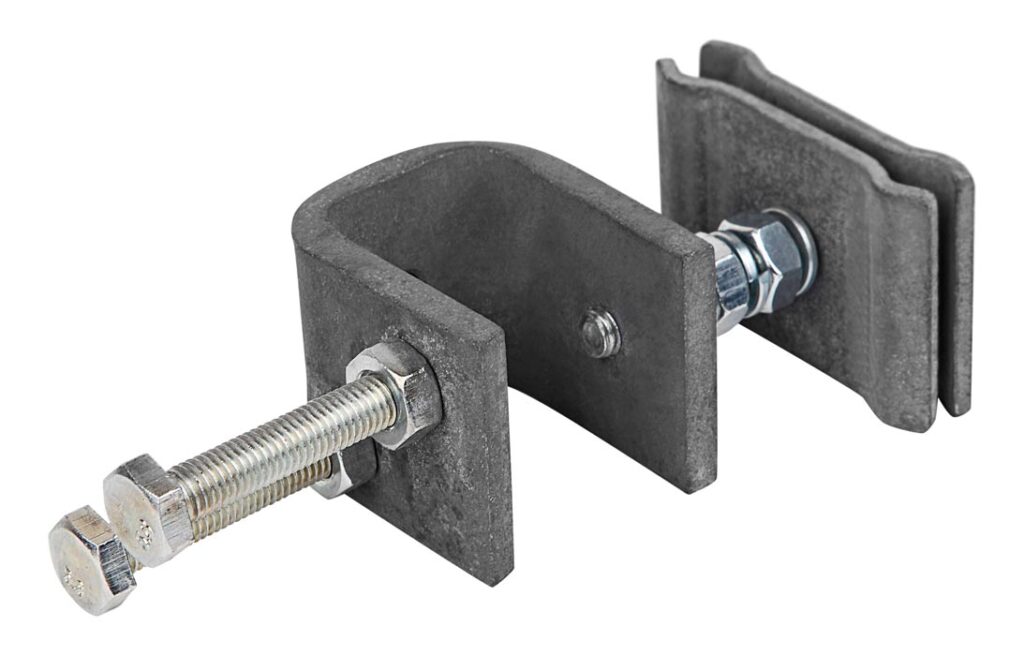

- Material – they are from durable and corrosion-resistant materials like galvanized steel or aluminum. The choice depends on factors like environmental conditions and the specific requirements of the applications.

- Adjustability – this allows them to accommodate a range of conductor sizes. This enhances flexibility during installation. IT also ensures a secure fit for various cable diameters.

- Corrosion resistance – corrosion resistant coatings protect the clamps from environmental factors. This is to ensure a longer service life.

- Installation ease – the design of the clamp facilitates easy and efficient installation. This includes features such as simple fastening mechanisms and clear installation instruction.

- Environmental adaptability – the design should consider the environmental conditions of the installation site. This includes temperature variations, humidity and exposure to salt spray.

- Durability – high quality materials, robust construction and resistance to environmental factors contributes to the long-term reliability of the clamp.

- Design for conductor type and size – their design may include features such as grooves or jaws to grip the conductor.

- Strength and load capacity – the clamps must have enough strength and load capacity to support the weight and tension of the downlead.

Selection and installation of downlead clamp

The selection of downlead clamp ensures the effectiveness, safety and reliability of the system. It includes considering factors such as material, adjustability, conductor type, adjustability, corrosion resistance, installation ease and security features. The installation includes various steps to ensure the secure and reliable connection between the overhead line and grounding system. the following is a general installation process of the downlead clamp.

- Preparation – collect all the necessary tools required for the installation. Thes include downlead clamp, suitable fasteners, wrenches and safety equipment.

- Inspection – inspect the downlead clamp to ensure it is in good condition and free from any defects or damage.

- Location selection – select the suitable location for installing the downlead clamp. Consider factors such as proximity to the overhead transmission line and type of structure.

- Cleaning and surface preparation – clean the surface to remove any dirt, rust or contaminants. This is to ensure a clean and smooth surface for optimal contact attachment.

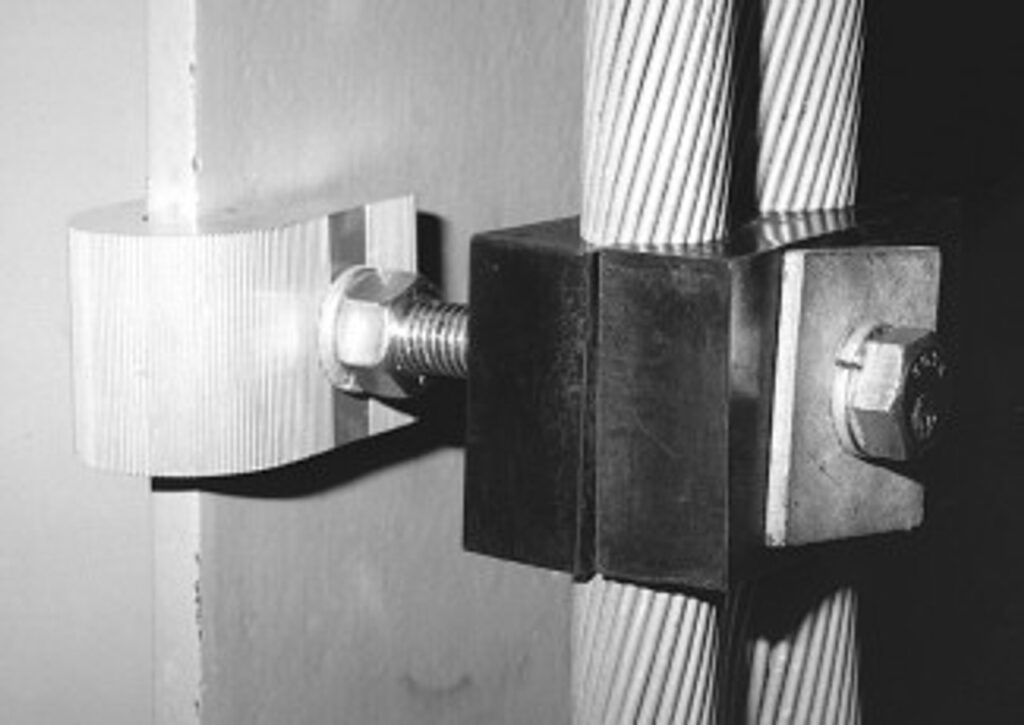

- Clamp positioning – position the downlead clamp on the conductor on the desired location. Ensure the clamp aligns and provides support and stability to the downlead.

- Fastening clamp – use the suitable fasteners to secure the downlead clamp to the conductor.

- Torque specifications – use a wrench to ensure the recommended torque. This helps to achieve the proper clamping force causing damage.

- Insulation – ensure the features are well positioned and do not interfere with the conductor. Insulation prevents unintended electrical paths.

- Final inspection – conduct a final inspection to ensure the downlead clamp is securely attached, aligned and free from any defects.

- Documentation – maintain detailed records of the installation. This is including the date, location and any specific details.

Maintenance and inspection of downlead clamps

Maintain and inspection helps to ensure the reliability and safety of an overhead transmission system. it also helps to identify and address potential issues that may cause failures and accidents. This helps to extend the lifespan of downlead clamps. It also ensures the continued reliability of the overhead transmission system. The following is basic guide for maintenance and inspection of downlead in South America.

- Preparation – collect all the necessary tools required for the installation. Thes include downlead clamp, suitable fasteners, wrenches and safety equipment.

- Inspection – inspect the downlead clamp to ensure it is in good condition and free from any defects or damage.

- Location selection – select the suitable location for installing the downlead clamp. Consider factors such as proximity to the overhead transmission line and type of structure.

- Cleaning and surface preparation – clean the surface to remove any dirt, rust or contaminants. This is to ensure a clean and smooth surface for optimal contact attachment.

- Clamp positioning – position the downlead clamp on the conductor on the desired location. Ensure the clamp aligns and provides support and stability to the downlead.

- Fastening clamp – use the suitable fasteners to secure the downlead clamp to the conductor.

- Torque specifications – use a wrench to ensure the recommended torque. This helps to achieve the proper clamping force causing damage.

- Insulation – ensure the features are well positioned and do not interfere with the conductor. Insulation prevents unintended electrical paths.

- Final inspection – conduct a final inspection to ensure the downlead clamp is securely attached, aligned and free from any defects.

- Documentation – maintain detailed records of the installation. This is including the date, location and any specific details.

Comparative analysis of downlead clamp in South America

Conducting a comparative analysis involves examining various aspects including product features, market trends and regional considerations. The analysis should consider both technical specifications and market context. Additionally, it is advisable to consult industry professionals for guidance on the best products to use. The following are the factors to include in a comparative analysis in South America.

- Market trends – identify the emerging trends in the market. This is including the adoption of smart technologies, increased focus on sustainability and integration of downlead clamps in electrical systems.

- Infrastructure projects – consider infrastructure projects in south America. Examine how the projects influence the demand for downlead clamps.

- Costs – check the cost of the downlead clamp considering factors such as pricing models, cost effectiveness and economic feasibility.

- Applications – get to know the applications of downlead clamps considering their use in urban infrastructure projects.

- Environmental conditions – consider the diverse environmental conditions in the region. Evaluate how the downlead clamp address the challenges such as humidity and corrosion resistance.

- Technological advancements – check any technological innovations in the design and manufacturing of downlead clamps.

Certifications and standards in South America

There are various standards and certifications for downlead clamps in South America. They ensure the quality, safety and reliability of downlead clamps used. Each south American country has their own set of standards and may adopt international standards. The following are the common standards and certifications in South America.

- IEC standards – this sets global standards for electrical and electronic technologies. Downlead clamps adhere to standards related to materials, design and performance.

- ISO certifications – this ensures that the downlead clamp meets international quality and performance standards.

- ABNT standards – this establishes standards for various industries in Brazil for use of downlead clamps.

- IRAM standards – this is responsible for setting standards in Argentina which regulates use of downlead clamp.

Regional market for downlead clamp in South America

There are various factors that influence the regional market for downlead clamps in South America. These factors include market trends, demand drivers and industry dynamics. Proper analysis of the factors helps to make informed decisions regarding the regional market for downlead clamps. Additionally, it is advisable to consult industry professionals for guidance on the best industry practices. The following are the various factors that shape the regional market for downlead clamps.

- Market trends – identify and analyse current market trends such as demand for sustainable and durable materials. Also, check the integration of smart technologies to enhance the reliability of electrical infrastructure.

- Costs – consider the pricing models, cost effectiveness and how economic factors impact the affordability.

- Environmental conditions – assess how downlead clamps in the market address environmental challenges.

- Emerging technologies – explore any emerging technologies in the field of electrical infrastructure in the region. This includes advancements in materials, design or smart technologies.

- Energy sector dynamics – this includes trends in power generation, transmission and distribution.

Frequently asked questions

A downlead clamp is a component used to secure and support the downlead cable that connects the overhead line to ground substation. Its purpose is to ensure a reliable and secure electrical connection while providing stability to south American applications.

Downlead clamps should consider diverse environmental conditions in south America. It should feature corrosion resistant materials, insulation and durability for various terrains.

Downlead clamps find use in applications like grounding systems, electrical substations, industrial installations, urban infrastructure projects and rural electrification.