A corona ring is a device used to control the occurrence of corona discharge in electrical systems. Corona discharge occurs when there is a high voltage gradient present. This is especially around the conductors which results into the ionization of the surrounding air. This creates a visible glow or aura and audible noise. Corona discharge can lead to power loss, electromagnetic interferences and equipment damage. Corona ring is a circular ring or ring-shaped conductors made of materials like aluminum or copper. It installs around high voltage components such as insulators, connectors or bushings. The rings help prevent the formation of corona discharge and reduces power loss. Corona rings serve as a visual indicator of high voltage. This helps to identify the areas of concern in electrical systems during maintenance.

The benefits of using a corona ring

Corona rings offers several benefits in the high voltage transmission systems. They provide efficiency, reliability, safety and durability. Corona rings contribute to the optimal operation of high-voltage systems. The following are the various benefits of using corona rings in your systems.

- Reduction of corona discharge – use of the rings aids to distribute the electric field gradient around high voltage components. This prevents the concentration of electrical stress that leads to corona discharge. Reduced corona discharge decreases power loss and reduces electromagnetic interference.

- Enhanced system performance – corona discharge introduces unwanted noise and disturbance into electrical systems. The rings contribute to a cleaner and more stable electrical environment to by controlling the corona discharge.

- Visual sign of high voltage – the rings show the presence of high voltage in electrical systems. This helps to identify the areas of high electrical stress during maintenance and inspections.

- Improved lifespan – corona rings help to protect high voltage components from damage. these components include insulators, connectors and bushings.

- Improved safety – corona discharge brings safety risks to personnel working with or near the equipment. This is because it may produce ozone, audible noise and create visible sparks.

Advantages of the corona effect

Corona effect is mainly considered undesirable in electrical systems due to the negative impacts. But sometimes it offers several advantages in specific applications. Additionally, it is advisable to consult with industry experts for guidance on the various advantages. The following are the common advantages of the corona effect.

- Ionization for air purification – the corona effect can help to ionize the air molecules in various applications. These include ozone generators and air purifiers.

- Corona discharge machining – controlled corona effect can serve in material removal in processes. These includes wire stripping and micro-machining. This allows for high-precision cutting and shaping of shaping of materials like polymers and tin films. This offers advantages to industries requiring intricate fabrication processes.

- High-voltage testing – the corona effect works in high-voltage testing procedures to detect insulation weaknesses. Technicians can access the integrity of insulation systems by inducing corona discharge.

- Electrostatic precipitation – the corona effect is behind electrostatic precipitators in various industries. It helps to ease the removal of particulate matter from exhaust gases and reducing pollution emissions.

- Corona treatment for surface modification – this is a surface modification technique used in industries. This works in industries such as printing and packaging. Controlled corona effect on materials improves the adhesion and promotes better coating coverage.

Industry advancements and updates in the corona ring industry

There are various advancements in the industry about the corona ring to address the emerging challenges. They bring improvement in performance, durability and efficiency in the high-voltage applications. Also, it is advisable to seek professional guidance when selecting the technologies. The following are the potential advancements and updates in the corona ring industry.

- Material innovation – there is development of new materials for corona rings that enhance their electrical properties. They also improve their mechanical strength and resistance to environmental factors.

- Integration with smart grids – the rings integrate with monitoring and diagnostic systems for maintenance. The rings could enable real-time monitoring of electrical parameters and early detection of potential issues.

- Standardization and certification – the efforts to develop international standards and certification programs for corona rings. They help to ensure consistency in quality and performance across different manufacturers.

- Research and development – there is ongoing research to explore new approaches of corona ring technologies. Areas of research include advanced materials, electron-magnetic modelling and field testing. This is to enhance the performance and applicability of corona rings in various applications.

- Design optimization – computational modelling and simulation techniques may help to refine shape, dimensions and placement of corona discharge. This is to maximize their effectiveness in controlling corona discharge while reducing setbacks.

- Environmental conditions – this is the increased emphasis on sustainability and environmental impact. This includes materials that reduce carbon footprint and meeting regulatory requirements.

- Application in renewable energy – corona rings find new applications in wind turbines and solar installations. They could help to improve grid reliability and efficiency.

Technical specifications of corona rings

The technical specifications of corona rings vary depending on various factors. These includes the application, voltage level and specific requirements. The specifications provide guidance for selecting and specifying corona rings. Additionally, the manufacturers should provide detailed datasheets outlining the technical parameters for their products. The following are the common technical specifications associated with corona rings.

| Production Name | High Voltage Corona Rings/Corona Control Rings |

| Raw Material of Corona Ring | Grade Aluminum Alloy 3A21/6061/6063 Stainless Steel ASTM 304 Copper |

| Material of Fasteners | ASTM 304 Stainless Steel |

| Surface Finish | Polishing Silvery Bright, Ra3.2 |

| Other Surface Treatment | Blue Color Painting/Galvanized/Coating insulating varnish |

| Ring Tube Wall Thickness | 2.0mm-10.0mm |

| Inner Diameter of Ring | Minimum 190mm |

| Outer Diameter of Ring | Maximum 16000mm |

| Production Type of Ring | Pipe Bending/Pressure Die Casting |

| Operating Voltage | 170kV-4200kV |

- Material – the rings are from conductive materials that provide conductivity, corrosion resistance and mechanical strength.

- Voltage rating – corona rings have designs to operate within a certain voltage range. The voltage rating of the corona ring should match or exceed the greatest voltage expected in the electrical system.

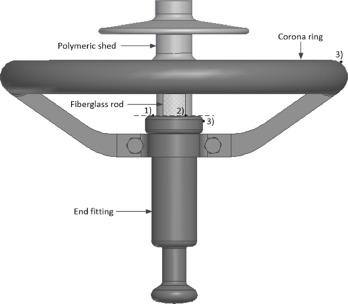

- Mounting mechanisms – the rings feature several mounting provisions. This is including holes, flanges or brackets for secure attachment. They attach to the high-voltage components such as insulators, bushings or conductors. The mounting mechanism should be compatible with the specific installation requirements.

- Shape and dimensions – the rings come in various shapes and designs. These include circular, oval or rectangular. Their dimensions have dimensions for specific components within the electrical system. The diameter, thickness and geometry of the corona ring have designs to optimize its performance.

- Surface finish – the surface finish of corona rings should meet specific requirements for electrical conductivity, smoothness and resistance. Such treatments help to enhance corrosion resistance and improve electrical performance.

Surface treatments for corona rings

Applying surface treatments to helps to enhance their performance, durability and resistance. The treatments are set to meet specific requirements of corona rings in various applications. This is to provide enhanced performance, longevity and reliability in high-voltage electrical systems. Selection of the surface treatments depends on various factors. These factors includes material composition, environmental conditions and functional properties. The following are common surface treatments for corona rings.

- Anodizing – this is an electrochemical process that creates a protective oxide layer on the surface of metal corona rings. Thie layer improves corrosion resistance and enhances electrical insulation properties. The anodized corona rings also have better adhesion properties for coatings or paints.

- Plating – some of the metal rings have a thin layer of another metal to improve their surface properties. This enhances corrosion resistance, provide a smoother finish and increase conductivity.

- Passivation – this is a chemical process used to remove surface contaminants and create a passive oxide layer. This layer improves corrosion resistance by acting as a barrier against moisture.

- Surface texturing – this includes techniques such as sandblasting or etching. They enable them to change the surface topography of the rings. Textured surfaces improve adhesion, reduce friction and promote better wettability for coatings.

- Coating – the rings have coatings to provide extra protection against corrosion, abrasion and environmental degradations. Common materials for coating include epoxy and polyurethane or silicone-based coatings. The coatings can also enhance electrical insulation properties and improve resistance to chemical exposure.

- Conversion coating – conversion coating modifies the surface of metal corona rings. This helps to improve adhesion, corrosion resistance and paintability. The coatings can enhance the bonding of the successive organic coatings.

Frequently asked questions

Corona rings help to mitigate corona discharge which can cause power loss, electromagnetic interference and equipment damage in high-voltage systems. By controlling corona discharge, corona rings improve systems efficiency, reliability and safety.

The technical specifications of corona rings include material composition, shape and dimensions, voltage rating and surface finish. They also include mounting mechanism, temperature rating and compliance with industry standards.

It is important to consider factors such as the voltage level of the electrical system, environmental conditions, material compatibility and mounting mechanisms. Also, consult with industry professionals for help in selecting the suitable corona ring for your specific application needs.