A cross plate anchor is a type of anchor used to secure the crossarms of utility poles or towers. It is also known as a cross-arm anchor. It helps maintain the stability and integrity of the system. The design and construction of cross plate anchors depends on various factors. These include the type of utility pole, materials used and the environmental conditions. It helps support the safe and reliable transmission of electrical power across long distances. Our high-quality cross plate anchors help to withstand the challenging weather conditions in Southeast Asia. This helps ensure the reliability of your overhead transmission lines. common types of cross plate anchors include single cross, double cross, triple cross, offset and corner cross plate. They find use in applications such as transmission lines, telecommunications, street lighting, utility distribution and cable TV distribution.

Key features of cross plate anchor

Cross plate anchors have specific features that help them improve safety and reliability. These features vary depending on its intended application and the manufacturer. The following are the key features of the cross-plate anchor.

- Material – the anchors are from durable and corrosion-resistant materials. They help to ensure long-term reliability in outdoor environments.

- Plate design – they consist of a plate or plates with holes or slots for fasteners. The design varies depending on the specific application and the number of crossarms it needs.

- Fastener compatibility – the anchors work with fasteners such as bolts, nuts and washers of specified sizes.

- Load capacity – cross plate anchors withstand the loads levied by the attached crossarms, cables, equipment and environmental factors.

- Corrosion resistance – the anchors have coatings that help them resist corrosion from various elements.

- Adjustability – they also allow for fine-tuning of the positioning of the crossarm to ensure proper alignment.

- Versatility – the anchors are applicable in various applications due to their versatility. These include telecommunication and street lighting.

- Ease of installation – cross plate anchors have a straightforward installation to increase effectiveness.

- Rust prevention – the anchors have zinc coatings which prevent rust and maintain their structural integrity.

Selection and installation of cross plate anchor

The selected cross plate anchor should ensure the stability and reliability of the system. It involves considering factors such as environmental factors, load requirements, industry standards, material, ease of installation and cost considerations. The installation should ensure safety and longevity of the supported structures. The following is a basic installation process of the cross-plate anchors.

- Preparation – ensure you have all the necessary tools and equipment and adhere to safety guidelines.

- Site assessment – identify the correct location on the utility pole or tower where the anchor will install.

- Marking – use a measuring tape and level to mark the exact position where the cross plate will attach.

- Drilling holes – drill holes in the utility poles based on the holes in the cross-plate anchor. The drilled holes should match the fasteners to use.

- Attachment – align the holes in the cross-plate anchor with the holes drilled in the pole. Insert the bolts through the holes in the anchor and through the corresponding holes in the pole. Place the washers and nuts on the other side of the bolts. Tighten the nuts securely to ensure the anchor is firmly attached and does not wobble.

- Alignment – use a level to check the cross-plate anchor aligns horizontally and vertically.

- Additional equipment – follow the manufacturers instructions for attachment of other components. These include like crossarms, insulators or other equipment on the cross-plate anchors.

- Quality assurance – double check the tightness of all nuts and bolts to ensure they are secure. This helps to confirm that it meets the safety and quality standards.

- Documentation – maintain records of all installation including date, location and any specific details.

Maintenance and inspection of cross plate anchor

Maintenance and inspection help to ensure the ongoing stability and safety of the structures they support. It also helps to identify and address issues before they turn to potential failures. Additionally, it is advisable to follow manufacturer recommendations and industry best practices. The following is a basic guide to maintenance and inspection of cross-plate anchors.

- Regularly inspect cross-plate anchors for signs of wear, corrosion or damage. Check for loose bolts, nuts or washers.

- Clean the anchors and free them from debris, vegetation and dirt. The accumulated dirt and moisture accelerate corrosion and reduce the lifespan of the anchors.

- Apply additional protective coatings or corrosion inhibitors to extend their lifespan.

- Replace any damaged components such as bolts or washer with new ones of the suitable material and specifications.

- Perform regular inspections of cross-plate anchors at intervals recommended by the manufacturer or by industry standards.

- Verify that the anchors are properly positioned and tightened according to the manufacturer’s guidelines.

- Ensure the cross-plate anchor has potential to support the intended loads which may also include testing.

- Maintain detailed records of inspections including the date, findings and any actions taken.

- Consider engaging a qualified engineer or structural expert. They should conduct a comprehensive inspection of the cross-plate anchors.

Comparative analysis of cross plate anchor

The comparative analysis of cross-plate anchors involves evaluating and contrasting different types and designs of anchor. This may depend on factors such as materials, design features, load capacities and suitability for specific applications.

- Materials – the anchors are from materials like galvanized steel, aluminum or composite materials. These materials may offer high strength, durability and lightweight features.

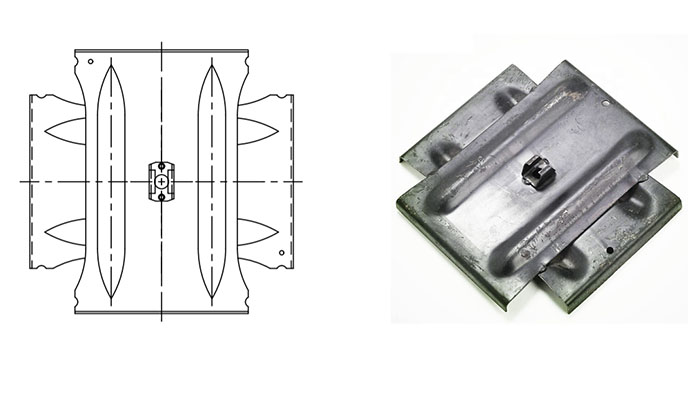

- Design features – there are various designs of the anchors such as single, double, triple and offset models.

- Load capacity – different cross plate anchors have varying load-bearing capacities. It helps to support the anticipated loads, including the weight of crossarms, conductors and environmental forces.

- Corrosion resistance – the galvanized features help to withstand corrosion.

- Compatibility – ensure the selected cross plate anchor is compatible with other components of the infrastructure.

- Warranty and support – ensure the selected anchors have a longer warranty period to confirm the anchor’s reliability.

- Industry standards – ensure the anchors complies with the relevant industry standards and regulations. These standards ensure safety and quality of the cross-plate anchors.

Certifications and standards in Southeast Asia

Cross plate anchors are subject to various certifications and standards. They help to ensure their quality, reliability and compliance with industry standards. Certifications and standards vary by region and application in Southeast Asia. Additionally, it is advisable to consult with local authorities, industry experts and relevant government agencies in Southeast Asia. The following are the common certifications and standards in Southeast Asia for cross plate anchor.

- ASTM standards – these relate to materials and structural components used in Southeast Asia.

- ISO standards – these standards relate to fasteners and structural components. They also cover mechanical properties of fasteners which applies to cross plate anchor fasteners.

- IEC standards – this provides standards for electrical and electronic equipment.

- Local and national standards – these are standards governing construction and infrastructure components.

- Manufacturer certifications – reputable manufacturers provide certifications and product specifications to confirm their products.

- Compliance with building codes – the cross-plate anchors must comply with the local building codes and regulations specific to the country.

Regional market for cross plate anchors in Southeast Asia

The regional market for cross plate anchors varies depending on various factors in the region. Some of these factors include infrastructure development, construction projects and utility expansion. These factors lead to the increased demand of cross plate anchors in Southeast Asia. Also, it is advisable for manufacturers and suppliers to observe the market trends in the country for success. The following are the common factors that influence the regional market for cross plate anchors.

- Telecommunication expansion – the growth of the industry such as 5G networks requires secure mounting solutions for antennas, cables and communication equipment.

- Urban development – this includes development of the urban areas such as street lighting among others. This requires the use of cross plate anchors to support this equipment.

- Maritime infrastructure – the coastline and numerous ports in Southeast Asia require anchor for maritime infrastructure. This may include use of cross plate anchors for stability.

- Competitive market – the competition in southeast Asian market is from the domestic an international manufacturer offering a wide range of products.

- Agricultural sector – cross plate anchors need to meet safety and quality standards set by local authorities. This helps to ensure reliability and durability of the application system.

- Renewable energy projects – the increased adoption of renewable energy sources such as solar wind power. Cross plate anchors help in the construction of solar farms and wind turbines for stability.

- Electrical transmission and distribution – the improvement of electrical grids help to expand access to electricity. This requires the use of cross plate anchors to secure the various components of these projects.

Frequently asked questions

A cross plate anchor is a structural component used to secure crossarms and support various utility infrastructure. It provides stability and reliability to the infrastructure projects in Southeast Asia.

Cross plate anchors mostly find use in applications such as overhead transmission lines, telecommunications networks, street lighting installations, renewable energy projects and maritime infrastructure.

Regular inspections help to ensure the integrity of cross plate anchors especially in the diverse climates of Southeast Asia. The frequency of inspections varies depending on the weather conditions or as specified by local regulations and industry standards.