A crossarm pin is a device used to support and mount and secure crossarm to the pole. It is a horizontal wooden or metal beams mounted perpendicular to the utility pole. The pin acts as a platform for attaching electrical insulators, conductors and other equipment. It is typically made of steel or other durable materials. It is available in different designs to accommodate different types of crossarms. A crossarm pin have three parts, the crossarm pin base, a crossarm pin body and the crossarm pinhead. South American power distribution networks require the use of high-quality crossarm pins. This helps them withstand the diverse environmental challenges in the region. The common types of crossarm pins include lag screw, clevis pin, angle pin and shoulder pin. They find use in applications such as crossarm attachments, insulator attachment, conductor support and hardware attachment.

Key features of crossarm pin

There are various features and components that enhance the functionality of crossarm pins. The available features depend on the specific requirements of the power line and type of crossarm used. The following are the key features of the crossarm pin.

- Material – crossarm pins are from durable materials that withstand different environmental conditions. These include steel, iron and aluminium.

- Threaded and non-threaded – the threaded ends are for secure attachment to utility poles. The non-threaded are for specific applications.

- Corrosion resistance – they have coatings or materials that resist corrosion to ensure longevity.

- Tension support – tension pins offer horizontal tension support to crossarms used in corner and dead-end structures.

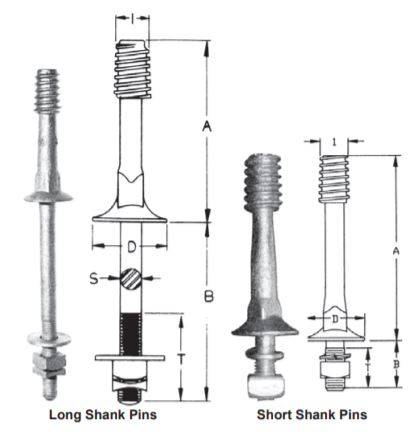

- Size and design – they are available in different sizes and designs. This helps to accommodate different types of crossarms, insulators and hardware.

- Insulator groove – they also have grooves to securely hold insulators in place to prevent them from shifting.

- Load capacity – they also support the weight of crossarms, insulators, conductors and other hardware.

- Ease of installation – the crossarm pins allow for easy installation that reduce labour costs and installation time.

- Compatibility – they should be compatible with the crossarms, insulators, conductors and hardware used.

- Cost effectiveness – they should offer cost-effective solution for securely attaching crossarms and other components.

Selection and installation of crossarm pin

Proper selection ensures safe and reliable operation of overhead power lines and utility poles. The selection process includes considering various factors. These include type of crossarm, application, load requirements and environmental conditions. The installation should ensure the stability and safety of overhead power lines. The following is a basic installation guide for crossarm pin.

- Preparation – gather all the necessary tools required for the installation. These include crossarm pin, utility pole, crossarm, insulators, hardware, safety gear and wrenches.

- Location – select the suitable location for installing the crossarm pin on the utility pole. Ensure it aligns with the requirements of the crossarm and hardware attached.

- Utility pole preparation – create a hole for the crossarm pin using a drill on the utility pole.

- Positioning – place the crossarm in the desired position on the utility pole and ensure it is level and properly aligned.

- Crossarm installation – insert the threaded end of the crossarm pin through the hole in the crossarm. Ensure proper resting against the crossarm if it has a shoulder.

- Securing – thread the non-pointed end of the crossarm pin into the hole or threading utility pole. Ensure proper tightness to offer proper support.

- Insulator and hardware installation – secure the insulators and hardware using suitable fittings.

- Safety measures – insert the cotter pin through the hole provided on the non-pointed end of the pin. Bend the ends of the cotter pin to secure it in place.

- Inspection – perform a visual inspection of the installation to ensure the crossarm, insulators and hardware have proper positioning.

- Documentation – proper documentation provides reference for future reference. It includes dates, types and pictures for the installation.

Maintenance and inspection of crossarm pin

Regular maintenance and inspection of the crossarm pin ensures the continued safe and reliable operation of overhead power lines. The frequency depends on the specific location and environmental conditions. Additionally, it is advisable to conduct professional maintenance and inspection once in a while. The following is a basic guide for the maintenance and inspection of crossarm pins in south America.

- Conduct visual inspections of the crossarm pins and check for signs of wear, damage or corrosion.

- Test the tightness of each crossarm pin by turning it by hand. Tighten any loose connections using the suitable torque levels.

- Inspect the condition of the conductors attached to crossarm pin ensuring no damage.

- Check the adjustment and tension regularly to ensure proper functioning and desired angle and tension maintained.

- Regularly clean the crossarm pin to remove dirt, debris and any corrosion accumulated on the surface.

- Apply lubricant to the threads to help prevent corrosion. This also offers easy adjustments and extend the lifespan.

- Replace any crossarms that show signs of wear, damage or not structurally sound.

Comparative analysis of crossarm pins in South America

A comparative analysis includes evaluating and assessing various aspects of the crossarm pins. This includes assessing, design, type and costs of different pins available. This activity helps identify the best-suited options that meet the specific needs of the region. Additionally, it is advisable to consult with regional experts to evaluate the performance of crossarm pins. The following are the key factors to include in a comparative analysis in South America.

- Load capacity – the pins should support the weight of conductors, insulators and hardware used.

- Compatibility – the crossarm pins should be compatible with the types of crossarms, insulators, conductors and hardware used.

- Angle and tension support – evaluate the availability of crossarm pins for the various power distribution systems.

- Longevity and durability – evaluate the service life of the crossarm pins which can impact maintenance costs.

- Local availability – the crossarms should be locally available and cost friendly.

- Versatility – the pins should also be able to work in a variety of applications and configurations.

- Environmental factors – they should also perform well despite the exposure to heavy rainfall, tropical storms or high humidity.

- Material and coating – crossarm pins should have coatings or materials that resist corrosion. This is due to exposure to humidity, coastal exposure or other climate factors.

Certifications and standards in South America

There are various standards and regulations that govern the use of crossarm pin in south America. These standards and certifications ensure the safety, reliability and interoperability of electrical components. Additionally, it is advisable to consult with local authorities to confirm the safety of the products. The following are the common standards and certifications in South America.

- IEC – Standards many south American countries adopt these standards for electrical equipment.

- ISO – these standards apply to the manufacturing processes and quality control of crossarm pins.

- ANSI – these standards provide guidelines for insulators and other electrical equipment.

- Local Regulatory Authorities – each South American country may have its regulatory authorities. They are responsible for setting standards and for issuing certifications for electrical equipment

- Safety Certifications – Crossarms should observe safety certifications depending on the intended market and application

- Environmental Regulations – some South American countries have regulations that govern the use of coatings, materials, and manufacturing processes.

- Product Testing – crossarm pins should demonstrate compliance with electrical, mechanical and environmental requirements through testing.

- Quality Management Systems – manufactures should implement quality management systems. This is also to ensure consistent product quality and adherence to standards.

Regional market for crossarm in South America

There are various market trends that influence the demand and supply of crossarm pins in South America. These trends vary from one country to another in the region. Also, it is advisable that manufacturers and suppliers observe these trends for the guaranteed success in the market. The following are the common factors that influence the regional market in South America.

- Growing power demand has seen an increase in electrical demand due to the population growth and industrialization.

- Renewable energy expansion often requires the expansion and upgrading power distribution infrastructure creating opportunities for crossarm pin manufacturers.

- Infrastructure development projects including the construction and maintenance of power lines, also contribute to demand for crossarm pins.

- Environmental factors can impact the longevity and corrosion resistance for crossarm pins. This may include humidity, tropical storms and coastal exposure.

- Economic stability, investment in infrastructure and public-private partnerships can affect demand for crossarm pins.

- Local manufacturing some countries may have local manufacturers and preference may favour their products.

- Competition competitive landscape with different manufacturers offering a range of cross arm pins with different features and price ranges.

Frequently asked questions

A crossarm pin is a device used to secure crossarms to utility poles. It helps in supporting insulators, conductors and hardware. This also helps to ensure stability of overhead power lines.

Crossarm pins should comply to international standards such as IEC, ISO and ANSI. It should also comply to local regulatory standards and certifications to meet each south American country.

The selection process includes considering several factors that include type of crossarm, load capacity, environmental conditions, compatibility and compliance with standards.