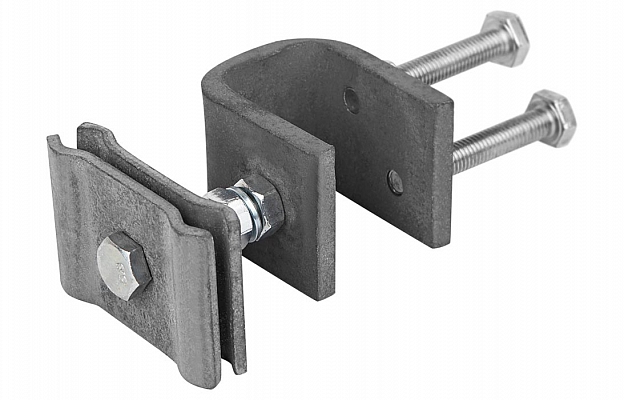

One tool used in overhead transmission lines and other applications is the downlead clamp. It aids in supporting and securing the electrical conductor downleads. The clamps are useful where conductors move from overhead wires to equipment. The clamp’s primary function is to give the conductor mechanical support and strain relief. By doing this, the conductor’s attachment to the structure is higher. Additionally, it permits flexibility to account for changes in temperature. Downlead clamps are from robust materials such composites, steel and aluminum. Both the environment and mechanical stresses can be efficiently handled by these materials. To stop the cable from vibrating in the wind, the downlead clamp holds onto it . Swaying could result in harm or disconnection.

The downlead clamp features

Many aspects of downlead clamps contribute to the safe and dependable support of electrical cables. They also guarantee the transmission infrastructure operates safely and effectively. The common characteristics of downlead clamps are as follows.

- Strong clamping mechanisms – the mechanisms provide a secure grasp on the cable. This stops it from vibrating. By doing this, the possibility of cable breakage reduces to ensure continuous power transfer.

- Weight distribution – the cables weight scatters throughout the structure through downlead clamps. This lessens the strain on the cable and the tower’s attachment points, preventing wear and tear.

- Grip and strength – galvanized steel give remarkable strength and longevity to downlead clamps. The premium material is resistant to extreme weather and severe winds.

- Reduced strain – when there is an accumulation of ice or a sudden blast of wind, the clamp buffers the tension on the cable.

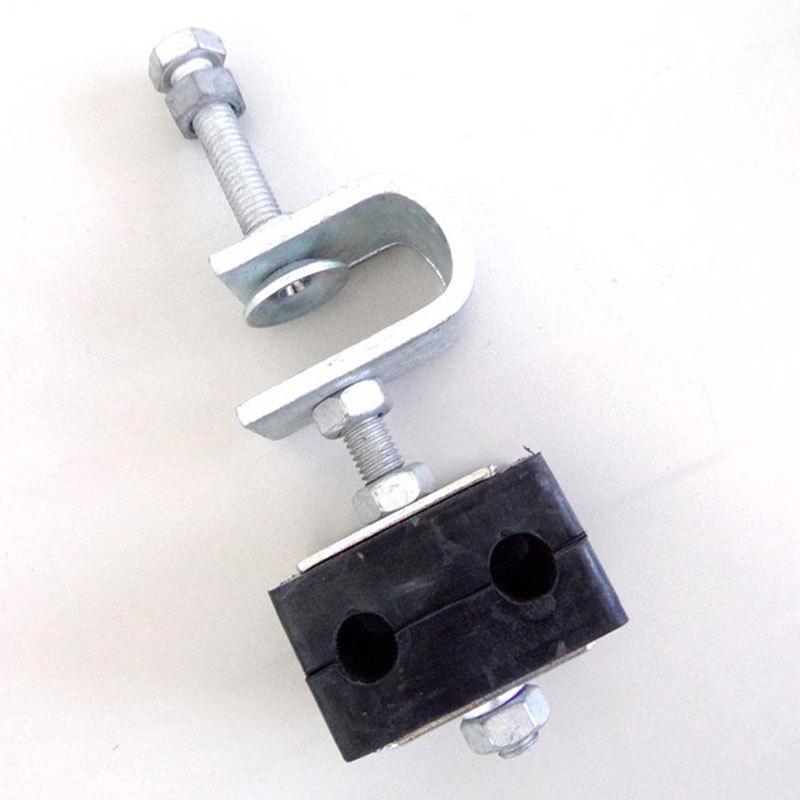

- Cable management – the clamps assist in keeping the appropriate distance between various cables. By doing this, entanglement reduces. This could result in power outages or short circuits. To shield the wire from abrasion against the pole, they also feature a cushion inside.

- Low maintenance – they need very little care because they are resistant weather conditions. Long-term dependable functioning is mainly enhanced by their design.

- Variety of sizes and designs – to suit a range of cable diameters and types, the clamps are available in a variety of sizes and designs.

- Connection options – the clamp’s adaptable connection points enable it to fix to a variety of pole shapes and materials. This guarantees interoperability with various infrastructure setups.

Downlead clamp’s areas of application

Downlead clamps work in many different applications to guarantee a controlled and safe cable succession. The clamps are useful equipment because of their adaptability and versatility. These are to guarantee the effective and safe movement of lightning, data or power. The different uses for downlead clamps in the industry are as follows.

- Power cables – these are cables that travel from overhead power lines to buildings get support and secure by electrical power distribution systems. They keep the cables tense and prevent sagging to provide a dependable electrical connection.

- Transmission lines – downleads get security and support by the clamps in high voltage transmission lines. The jumper wires that link the distribution equipment to the transmission lines are also included in this. They support the connections’ integrity and stability.

- Telecommunication – coaxial, fiber optic and communication cables are all supported and secured by downlead clamps. They are applicable in data centers, telephone networks, cable TV and broadband internet.

- Installing antennas – the clamps hold up the cables that link the antennas to the communication devices. They also keep the antennas aligned and positioned. This guarantees the best possible transmission and reception.

- Street signs and traffic lights – traffic control devices are also supported and secured by wires that held in place by clamps. This guarantees the electrical connections’ stability and dependability in outdoor settings.

- Outdoor applications – downlead clamps work in outdoor lighting to fasten the cables that link lighting fixtures to power sources. Additionally, they aid in relieving and shielding the cables from outside influences like wind and physical collision.

- Cable management – downlead clamps can work in a variety of situations for general cable management needs. Buildings for residential, business and industrial use are also included in this. They also assist in securing and organizing wires that run along poles, buildings and other structures.

Choosing downlead clamps

Selecting downlead clamps contributes to a controlled and secure cable origin in transmission lines. It entails taking into account some factors that affect the clamps decision-making process. When choosing a downlead clamp, keep the following things in mind.

- Corrosion resistance – to avoid damage, choose a clamp made of materials resistant to corrosion. It also contributes to long-term dependability.

- Voltage rating – verify that the transmission lines voltage levels are well rated. Electrical characteristics and insulation determine the voltage rating. This keeps both performance and safety intact.

- Cable kind and diameter – the clamps have to work with the size and kind of wire that used. Take into account the material composition, conductor diameter and configuration.

- Mechanical strength – examine the downlead clamp’s mechanical strength. Make sure the mechanical stresses won’t break them. This is particularly true when it comes to installation, operation, and surroundings.

- Installation technique – verify the installation’s simplicity and compatibility with existing hardware.

- Costs – take into account elements including the original outlay, installation costs and upkeep needs.

A guide for installing downlead clamps

Downlead clamp installation involves a few different stages. They guarantee that the overhead line and grounding system are well connected in a safe and dependable manner. It is also a good idea to seek advice from industry professionals about the most effective way to install your downlead clamp. The downlead clamp installs generally as shown below.

- Preparation – this is by gathering all the instruments needed for the installation. These consist of a downlead clamp, the appropriate fasteners, wrenches and safety gear.

- Examination – check the downlead clamp to make sure it is not damaged and in good working order.

- Location selection – decide where the downlead clamp should install. Take into account elements like the kind of construction and its closeness to the overhead transmission line.

- Cleaning and surface preparation – clean the surface to get rid of any pollutants, rust or dirt. This will guarantee a smooth and clean surface for the best possible contact attachment.

- Clamp placement – put the downlead clamp where you want it on the conductor. Make sure the clamp is in alignment and that it gives the downlead stability and support.

- Fastening clamp – to secure the downlead clamp to the conductor, use the appropriate fasteners.

- torque specifications – make sure the suggested torque applies with the help of a wrench. This aids in producing the appropriate clamping force that causes damage.

- Insulation – make sure the components position and don’t obstruct the conductor. Unintentional electrical paths reduce by insulation.

- Last check – make sure the downlead clamp is firmly fastened, straight and defect-free by performing a last check.

- Documentation – keep thorough records of the installation, noting the time, place and other specifics.

Upkeep procedures for the downlead clamp

An overhead transmission system’s dependability and security enhance by routine maintenance. It also aids in locating and resolving possible problems that could lead to malfunctions and calamities. It also contributes to the downlead clamps longer lifespan and the overhead transmission systems ongoing dependability. This is a basic guide to downlead clamp maintenance.

- Examine any mechanical problems, such as alignment errors, cracks or deformities. This preserves the integrity of the structure.

- Verify that the conductor and the supporting structure have the proper alignment.

- Examine the downlead clamps entire surface, paying particular attention to joints, welds and places where different metals are present.

- Test the downlead clamp’s resistance to environmental factors. Look for evidence of deterioration brought on by UV exposure.

- Examine the downlead clamps on a regular basis to look for physical damage, corrosion or wear.

- Check the area on a regular basis to look for indications of wear, corrosion or physical damage.

- Clean off any dust, debris and other corrosive materials of the downlead clamp. To keep the surface’s electrical conductivity at its best and to stop corrosion, clean it.

- Treat the downlead clamps with chemicals or coatings that resist corrosion when exposed to high humidity or corrosive conditions.

- Verify the tightness of the fasteners and tighten them to the torque specifications as advised.

- Take into account the installation site’s climatic factors and deal with issues like excessive heat and humidity.

- To ensure electrical safety, check the insulation for damage and replace any damaged parts.

- Hire experts with the necessary training to inspect the complete overhead transmission system.

- Keep documentation of the installation, including the date, the location and any details about the downlead clamp.

Frequently asked questions

The clamps use various clamping mechanisms to grip the conductor without damaging it while providing a tight and reliable connection.

Consider factors likeconductor size and type, voltage rating, mechanical strength, corrosion resistance, environmental conditions and installation methods.

Downlead clamps lay a crucial role in maintaining the integrity of overhead transmission lines by supporting conductors.