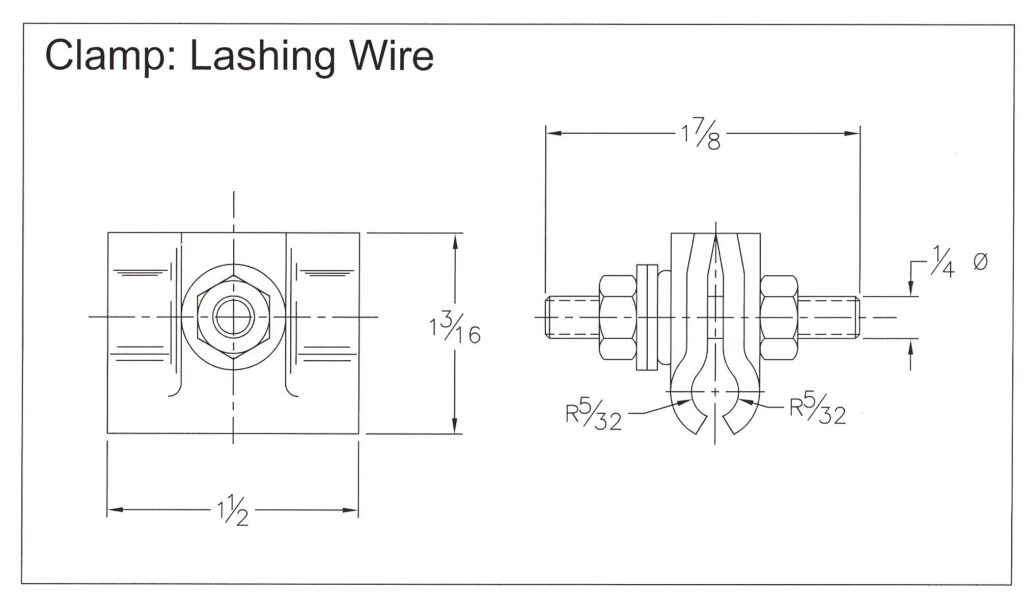

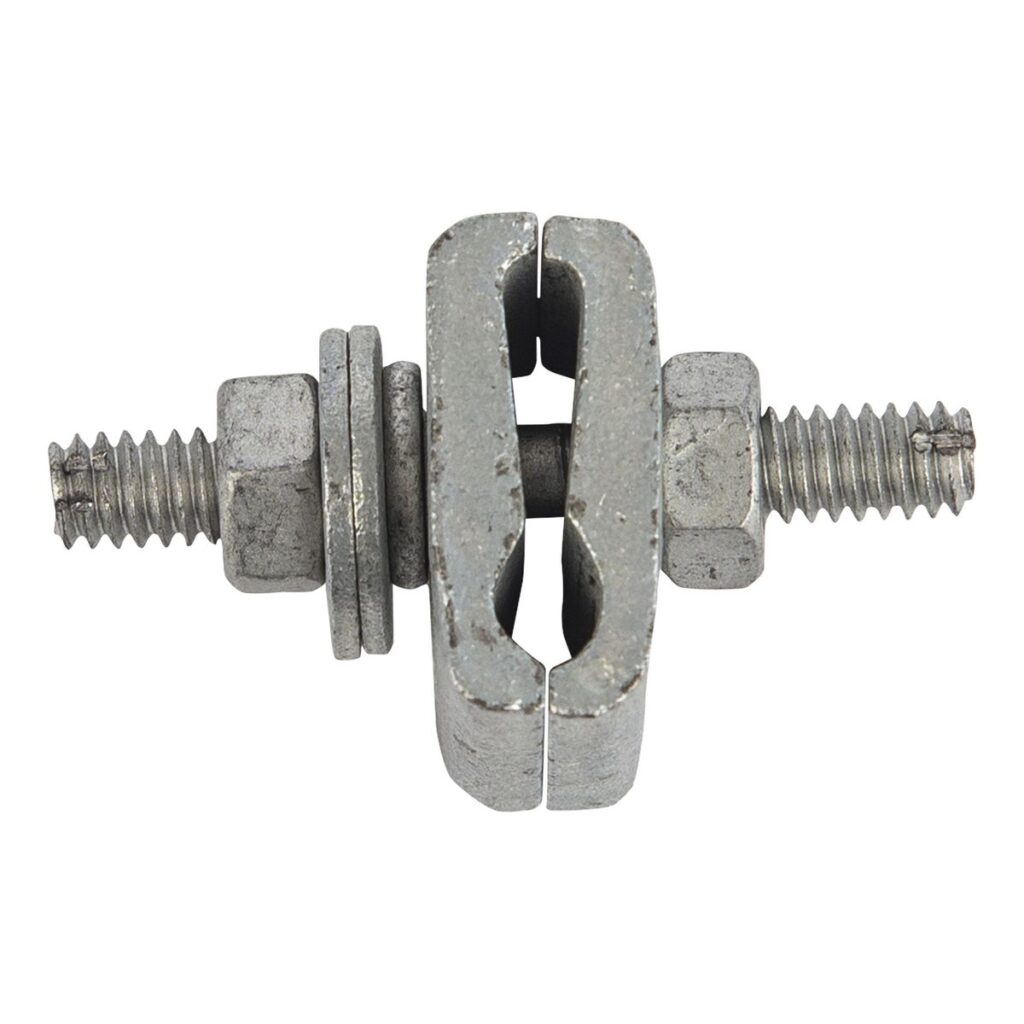

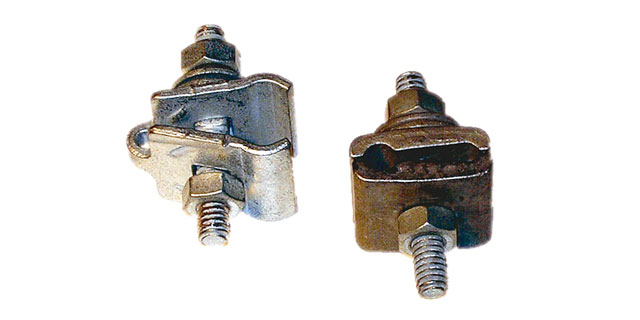

A lashing wire clamp is also known as a cable lashing clamp. It is a device used for securing wires to a support structure in electrical systems. It also helps to align, secure and support cables to ensures reliability and safety. A lashing wire clamp it consists of a stud, two washers and two nug nuts. It manufactures from stainless steel which helps resist corrosion. South American companies focus on the use of high-quality lashing wire clamps. This is because they help to maintain the integrity of the transmission networks. The two main types of lashing wire clamps include the D wire clamp and the E wire clamp. Other types include bolted, griplock, preformed and adjustable lashing wire clamps. They find use in applications such as tensioning, cable support, alignment and securing cables.

Key features of lashing wire clamps

Lashing wire clamp consists of various features that help to ensure the secure and reliable installation of cables. The choice of the lashing wire clamp depends on the specific project requirements and environmental conditions. The following are the key features of lashing wire clamps.

- Design – the clamps are available in various designs. These include bolted, griplock, preformed, j-hook and saddle. These are available for specific cable sizes and applications.

- Adjustability – the clamps allow for fine tuning to fit specific cable diameters.

- Material – they are from durable materials like galvanized steel or aluminum. They help to provide strength and resistance to corrosion.

- Compatibility – the lashing wire clamps can accommodate a range of cable sizes. This helps to allow for versatility in securing different types of cables.

- Gripping mechanism – they have several gripping mechanisms for security. These include bolts, locking mechanisms, helical designs and saddle shapes.

- Ease of installation – lashing wire clamps have easy installation process that can work by using hand or tools.

- Load rating – the clamps have specific load capacities to ensure they support the weight of the cables.

- Corrosion resistance – they may also have coatings to resist corrosion. This helps to ensure they maintain structural integrity.

- Environmental resistance – lashing wire clamps are able to withstand a range of environmental conditions. This is including exposure to weather UV radiation and extreme temperatures.

Selection and installation of cable lashing clamp

Proper selection of the lashing wire clamp helps to ensure the secure and reliable installation of cables. It also depends on various factors which include environmental conditions, costs, material, load capacity, clamp type and adjustability. The installation process should help secure the attachment of cables to the support structures. Additionally, it is advisable to consult with industry professionals when in doubt. The following is a basic installation guide for the lashing wire clamp.

- Preparation – gather all the necessary tools required for the installation process. This includes lashing wire clamps, cables, support structures and mounting hardware. Ensure you have all the suitable safety gear and the work are is fully de-energized.

- Inspection – check the lashing wire clamp for any sign of damage or wear. Ensure you have the correct type and size for the cables to secure.

- Positioning – select the suitable location on the support structure to install the clamp. Position it to align with the cables desired path and spacing.

- Preparation – arrange the cables neatly and ensure they align and ae properly spaced.

- Open the clamp – open the clamp to create a space for cables.

- Place the cables on clamps – insert the cables into the clamps open space and ensure they center and properly seat within the clamp.

- Secure the clamp – align the two halves of the clamp and secure them together using the specified fasteners. Engage the clamps locking mechanism to securely hold the cables in place.

- Tightening – adjust the clamp to achieve the desired tension on the cables.

- Inspection – visually inspect the installation to ensure the clamp securely attaches to the cables. There should be no signs of slippage or misalignment.

- Documentation – keep detailed records of the installation. This is including date, location, type of clamp used and cable details.

Maintenance and inspection of lashing wire clamps

Proper maintenance and inspection ensure continued reliability and safety of overhead transmission systems. It also helps identify issues that could lead to accidents or electrical hazards. Additionally, it is advisable to conduct professional maintenance and inspection once in a while. Frequency of this depends on the environmental factors in South America. This may be due to harsh weather, UV radiation and temperature extremes. The following is a basic guide for maintenance and inspection of lashing wire clamp.

- Perform regular visual inspections to check for signs of wear, damage or corrosion on the lashing wire cable. Check for any loose bolts, cracks or deformities in the clamp.

- Ensure the cables are properly aligned and spaced according to specifications.

- Check the tension of the cables within the clamp and ensure it is within recommended range.

- Inspect any safety features on the clamp to confirm proper functioning.

- Regularly clean the lashing wire clamps to remove dirt, debris and contaminants. This helps to reduce corrosion and improve performance.

- Apply anti corrosion coatings to lashing wire clamps to protect them from rust and degradation.

- Check and tighten the bolts to the recommended specifications.

- Apply lubricants to the moving parts to reduce frictions and improve performance.

- Replace any damaged or corroded lashing wire clamps to prevent a potential failure.

Comparative analysis of lashing wire clamps in South America

A comparative analysis of lashing wire clamps involves assessing and evaluating different clamps. This is examining the types, sizes, designs, brands, market trends and manufacturers available in the South American market. Additionally, it is advisable to keep heed to the different manufacturers and suppliers available in the market. The following are the key factors to include in the comparative analysis.

- Type of lashing wire clamp – there are various types of lasing wire clamps available in the market. The selection depends on the specific application and environmental conditions in the region.

- Applications – lashing wire clamp find use in various South American applications. Main applications include power transmission and distribution systems.

- Market trends – various market trends affect the decision-making process of lashing wire clamp. The various trends include grid expansion, safety regulations, local manufacturing, sustainability, import and export.

- Costs and quality – the costs of the clamps depend on material, designs and features available. It is important to balance cost with quality and safety of the clamp.

- Supply chain – the region has both local and international manufacturers and suppliers. Consider the reputation, quality and customer support.

Certifications and standards of lashing wire clamps in South America

There are various standards and certifications that govern the use of lashing wire clamp in South America. These standards help to ensure the safety, quality and reliability of lashing wire clamp. Also, it is advisable to consult with local authorities for an understanding of these standards. The following are the standards and certifications in South America.

- IEC standards – these are global standards adopted in South America for use of overhead electrical components.

- ISO certifications – this certification helps to ensure quality and safety of electrical equipment.

- ASTM standards – these are standards provide guidelines for materials, dimensions and testing procedures.

- Local electrical codes – each South American country have their own set of national standards related to lashing wire clamps.

- IECEE CB scheme – this is an international system for mutual acceptance of test reports and certificates in dealing with safety.

Regional market for live wire in South America

There are various factors that influence the regional market for lashing wire clamp in South America. These factors may include infrastructure development, environmental conditions and safety standards. Therefore, manufacturers and suppliers should observe these trends for safe operations in the region. The following are the factors that shape the regional market for lashing wire clamp.

- Renewable energy integration – lashing wire clamps help in the connection of renewable energy generation sites to urban centres.

- Maintenance and replacements – regular maintenance and replacement increase the demand for lashing wire clamps.

- Regional variations – preferences for the clamp vary in the region depending on climate, terrain and local regulations.

- Economic conditions – economic stability in the region drives the investment in power infrastructure projects. These in turn increase the demand for lashing wire clamps.

- Competition – availability of local and international manufacturers impacts the supply and availability of lashing wire clamps.

- Grid expansion – the expansion of the grid requires the use of new transmission lines. This in turn drives the demand for lashing wire clamps.

- Import and export – import in South America depends on cost, quality and availability of the lashing wire clamps. Local manufacturers may also export to the neighbouring countries thus affecting supply and demand.

Frequently asked question

A lashing wire clamp is a component used to secure cables to supporting structures in overhead transmission lines. It helps to provide support, alignment and tension to the cables. This is to ensure reliability of the electrical power system.

When selecting a lashing wire clamp, consider cable specifications, environmental conditions, load capacity, safety features, compliance with standards and application requirements.