A pin type insulator supports and insulates the electrical conductors. There are various types of insulators used on the lines known as electrical insulators. We will discuss the insulators known as the pin type insulator or basically, just a pin insulator. It consists of a porcelain or glass unit mounted on a metal pin. This factor gives it the name “pin type” insulator. The pin insulator withstands the high voltages and provide insulation between the energized conductor and the structure.

Components of the pin type insulator

Every device used on the transmission lines have unique features that make energy transfer easier. The components work with other fittings to ensure efficiency and reliability of energy transmission. They also work together to provide electrical insulation, mechanical support and environmental protection in a pin type insulator. They also ensure safe and efficient operation of the overhead transmission lines. Discussed below are the various components of the pin type insulator.

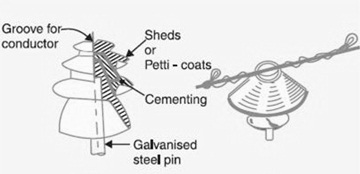

- Insulating component – the insulting component is the main component of the pin type insulator made from porcelain and glass materials. These materials help to provide insulation and resist other environmental conditions. The unit is in the form of a cylindrical or disc-shaped structure.

- Metal pin – this is a metal rod that serves as the support for the insulating unit made of galvanized steel for corrosion resistance. The metal pin attaches to the supporting structure and provides mechanical strength and stability to the insulator.

- Grooves – the insulating component has grooves on its outer surface. They help in distributing the mechanical load evenly and provide additional insulation. This is by increasing the surface distance between the conductor and the supporting structure.

- Metal caps – some of the pin type insulators have a metal cap on top of the insulating component. This cap provides protection against environmental factors. They also prevent moisture from entering the insulator.

- Grading rings – grading rings are optional components of the insulator included on the insulating component. They are conductive rings installed near the top of the insulator. They also cut the concentration of electric stresses and help improve the voltage distribution.

Types of pin type insulators used on the transmission lines

As already discussed, there are various types of insulators used on the transmission for the proper discharge of electrical current. The same applies to the pin type insulators as there are various types used on the overhead lines. Each of the pin type insulators varies depending on factors such as the voltage level, mechanical requirements, environmental conditions and specific needs of the transmission line system. The common types are as discussed below.

- Guy strain insulator – these help to insulate and support guy wires used to anchor poles or towers. Their design aims to withstand tension and mechanical loads on the overhead transmission lines. They have a disc shape and may be solid-core or multi-piece depending on the voltage requirements.

- Solid-core pin insulator – this is the most common type of pin insulator used for power transmission lines. it consists of a single solid porcelain or glass insulating component mounted on a metal pin. These types of pin insulators work in medium voltage applications. They provide good electrical insulation and mechanical strength.

- Composite pin insulator – these insulators are from a combination of polymer materials. They offer advantages like lighter weight, high strength and excellent resistance to environmental conditions. They mostly work in areas with high pollution, coastal regions and areas susceptible to wreckage.

- Multi-piece insulator – the insulating component divides into several segments or shells stacked together. These insulators offer increased flexibility which allow for easier installation and replacement. They mostly work in low to medium voltage applications.

- Long-rod insulator – long-rod insulators work in high voltage transmission lines. They consist of a series of porcelain of glass insulator disc connected by metal rods. The long rod design provides increased creepage distance. This distance allows for higher voltage ratings and better performance in polluted environments.

Applications of the pin insulators

There are many applications in the fields which require the use of pin insulators for proper transmission. The type of pin insulator used in a project depends on voltage level, environmental conditions and the type of power system. The main purpose of the insulators is to provide electrical insulation and mechanical support. The key applications of pin type insulators are as follows:

- Pin type insulators help to support and insulate the conductors in overhead transmission lines. This ensures safe and reliable transmission of power over long distances.

- The insulators work in substations to insulate various equipment and components. These components include bus bars, disconnect switches and circuit breakers.

- Their material and designs allows them to work in high voltage transmission lines. This is because the materials allow them to withstand high electrical stresses.

- Pin type insulators work in distribution lines which carry electricity from substations to residential, commercial and industrial areas. They support the conductor and prevent leakage of current to the supporting structures.

- In electrified railway systems, pin type insulators support and insulate the overhead catenary wires that supply power to the trains. They ensure high voltage catenary wires isolate from the supporting structures and the ground.

- They are also utilized in telecommunication lines to support and insulate communication cables. This helps to prevent interference and electrical leakage.

Installation of the pin type insulators

Pin type insulator installation requires careful adherence to safety protocols and industry standards. Specific installation process depends on the system and equipment used. Also, consult manufacturer guidelines and local regulations for specific instructions and requirements. If needed, you should involve experienced professionals to ensure safety and compliance. The following are the steps involved during pin type installation.

- Ensure all the necessary safety measures are in place. Verify that the insulators and associated equipment are in good condition. They should be suitable for the voltage end environmental conditions.

- Determine the appropriate locations for installing the insulators along the transmission lines. They usually place at regular intervals to support the conductors and maintain proper clearances.

- Attach the metal pin of each insulator to the supporting structure using appropriate hardware. Ensure that the pins are tight and that the insulators align vertically.

- Connect the conductors to the insulators using suitable fittings such as clamps, bolts or nuts. Following the manufacturer’s guidelines and industry standards.

- Connect the insulator disc using the provided metal rods in the place of long-rod insulators.

- Verify that there is appropriate mechanical clearance between the conductors and other objects. Also, ensure that the conductors are properly tensioned to maintain the desired sag and mechanical stability.

- Conduct a thorough inspection of insulators, fittings and connections. This is to ensure they are secure and free from any defects or damages. Also perform electrical testing to verify the integrity of the insulation system.

- Establish a regular maintenance and monitoring program to ensure the ongoing performance. This involves periodic inspections, cleaning and replacement of any damaged or worn-out components.

How to choose the best pin insulators for your project

Getting to know whether your application needs a pin insulator and which type to use can be hard sometimes. This is a common question from project managers or owners. Also, consult with industry experts or professionals who can provide valuable insights. The following are some factors to consider when selecting a pin type insulator.

- Determine the voltage level of the transmission line since they are available in various voltage ratings.

- Consider the mechanical requirements of the application. These includes the weight of the conductor, wind loads and tension.

- Evaluate the environmental conditions at the installation site. Consider factors like humidity, pollution, temperature variations and seismic activity.

- Consider the material of each pin type insulator and which works with your kind of application.

- Choose an insulator with good pollution performance to resist the accumulation of contaminants. This is to reduces the risk of flashovers and maintaining the insulation performance.

- Evaluate the electrical characteristic of the insulator. This is to determine its ability to withstand electrical stresses.

- Consider the relevant international or local standards and regulations governing the selection and use of pin type insulators.

- Consider the reputation and reliability of the manufacturer or supplier. They should have a track record of delivering high quality insulators.

Frequently asked questions

Main function of the pin type insulator is to provide electrical insulation to the overhead transmission lines. Other functions include electrical insulation, mechanical support, environmental protection and easy installation and maintenance.

An insulator pin is also known as line post insulator used to mount insulators on supporting structures. It is cylindrical in shape and provides a stable base for the insulator. A pin type insulator works in transmission lines to support and insulate electrical conductors. It helps to provide electrical insulation.

Pin type insulators have various limitations that reduce their adoption in the transmission industry. Most common include voltage limitations, mechanical stress, require maintenance, fragile, relatively heavy and high costs.