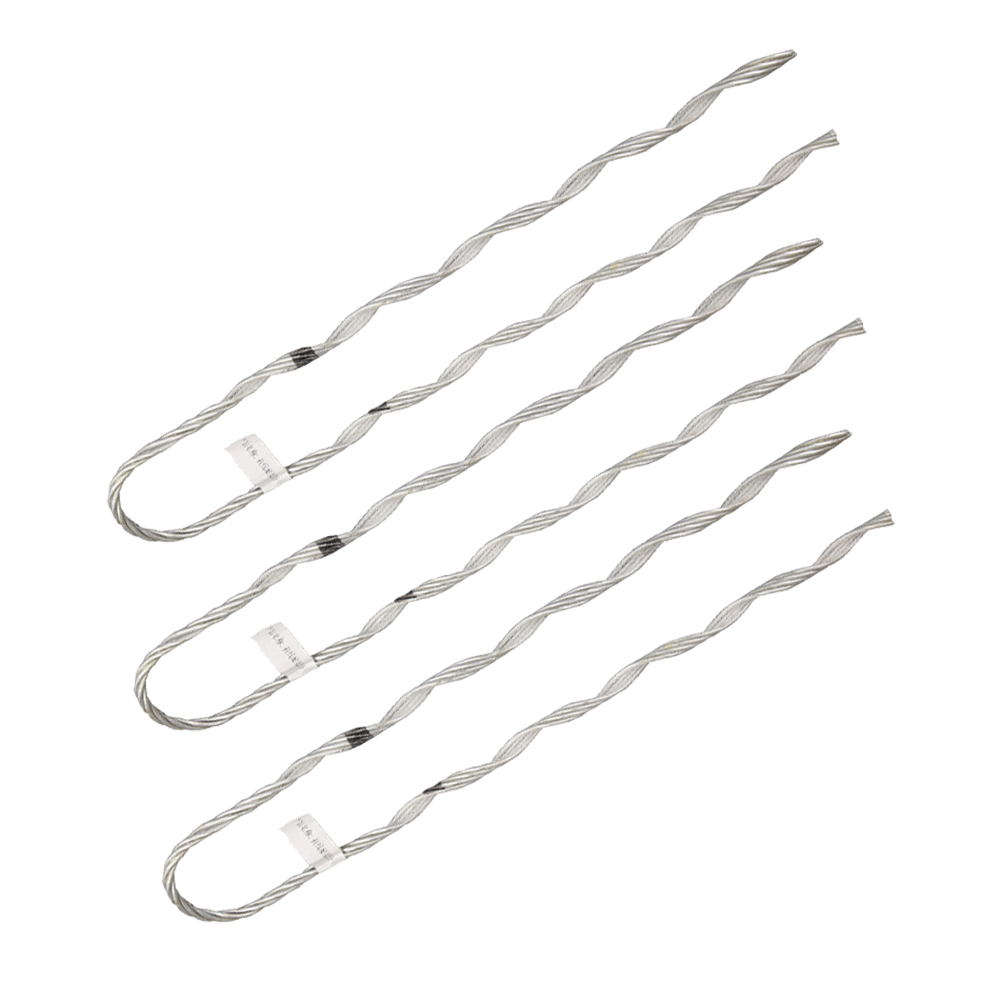

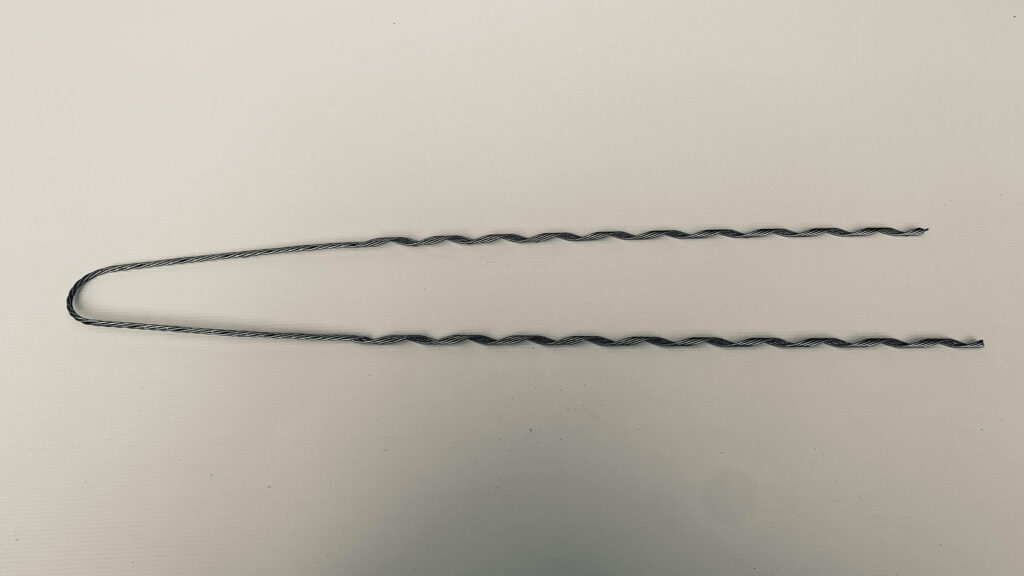

A false dead end is a support structure in which conductors anchor but continue on to the next support without finishing. It provides the illusion that the line does not extend beyond that point. This is to dissuade animals and humans from climbing. False dead ends give mechanical support to control the tension and weight of the conductors. They contribute to the integrity and stability of the transmission line. They operate at spots where the transmission line switches directions. The anchoring helps to manage extra forces and stresses during these directional alterations. This also helps to spread the mechanical load along the whole length of the transmission line. False dead ends make it easier to maintain and split the line. False dead ends are from steel, aluminum, and composite materials.

Advantages of using a false dead end

False dead ends offer various advantages to transmission lines. This includes boosting the system’s performance, reliability, and maintainability. The dead ends ensure that the transmission cables are stable, durable, and reliable. This is by decreasing sagging, distributing loads, and offering extra support. The following are some common advantages of utilizing false dead ends.

- Mechanical stability and strength – false dead ends give support for transmission lines. This is by preserving conductor tension. By anchoring the conductors, the dead end contributes to the structural integrity of the transmission system.

- Enhanced durability – the use of false dead ends improves the transmission line’s durability. These anchoring points aid in stress management caused by external stimuli. This includes wind, ice, and temperature variations.

- Improved dependability – false dead ends provide extra points of support and tension control. This reduces the likelihood of conductor sagging, snapping, and other problems. This helps to provide a consistent and stable power supply in high-demand locations.

- Directional changes – the dead ends offer the necessary support to withstand the higher lateral stresses. This helps keep the conductors aligned and reduces stress on the support structures.

- Load distribution – the dead ends spread the mechanical load along the whole length of the line. This reduces stress on individual poles, preventing structural breakdowns.

- Operation flexibility – they also improve transmission line management and maintenance by allowing for greater operational flexibility. They allow sections of the line to remain isolated during repairs or maintenance.

- Reduced sagging – conductor sagging can cause a variety of difficulties. This includes a lower clearance from the ground. The use of artificial dead ends helps maintain adequate tension in the conductors, preventing sagging.

The performance characteristics of a false dead end.

There are several methods for evaluating the performance of the false dead end in transmission lines. The features determine how well false dead ends can sustain, stabilize, and protect the transmission cables. False dead ends contribute to the efficiency and safety of the electricity transmission network. The false dead ends’ performance characteristics are as discussed in detail below.

- Load bearing capability – false dead ends must be able to withstand heavy loads. This is to handle mechanical stresses caused by the conductors. They should be able to withstand both tensile and compressive strength.

- Directional stability – dead ends should give support for lateral forces. They should verify that the structure can withstand side-to-side loads without bending. They should also be able to keep the conductor aligned.

- Ease of installation and maintenance – they should have easy-to-assemble, disassemble, and replace components. They should also include features that enable for easy examination and maintenance.

- Environmental adaptability – false dead ends should function well under a variety of environmental situations. They should be able to preserve structural integrity and performance. They must also be able to perform under difficult weather conditions. This includes wind, severe snow, and ice accumulation.

- Tension management – false dead ends have designs to manage and maintain the appropriate tension in the conductors. They should prevent conductor sagging and keep them firm to maintain a safe clearance from the ground. They should also be able to mitigate the effects of dynamic loads.

- Safety and compliance – false dead ends must adhere to safety standards and regulatory requirements. They should also provide adequate insulation to prevent electrical failures and ensure safety.

- Mechanical flexibility – they should have enough flexibility to absorb and cut the impacts of dynamic stresses. This helps to mitigate the effects of vibrations induced by wind or mechanical oscillations.

The Tensile Strength of Dead Ends

The tensile strength of false dead ends is a performance attribute that ensures they can withstand mechanical stress. Tensile strength is the greatest amount of tensile force that false dead end can withstand without failure. Additionally, the strength depends on the materials used, design criteria, and load ratings. Tensile strength is critical to the dependability, safety, and efficiency of the power network. Adequate tensile strength helps to prevent mechanical failures, maintain line integrity, and improve the safety of dead ends. The following are the factors to consider when determining the tensile strength of false dead ends.

- Material composition – false dead ends are from galvanized steel, aluminum alloys, and composite materials. They have a high strength-to-weight ratio, are durable, and resistant to corrosion.

- Design specifications – false dead ends designs vary by particular standards that govern their tensile strength. The standards ensure that they can withstand the greatest expected loads.

- Load ratings – the dead ends have ratings for specific load capacities. These ratings provide a safety margin to assure reliability under the most stressful conditions.

- Standards and testing – false dead ends should adhere to appropriate industry standards and laws. They establish rules for the design and testing of dead ends.

Testing for false dead ends.

Testing false dead ends ensures they meet the performance requirements. This is to support the mechanical loads placed on the wires. The testing process includes preparation, execution, post-test analysis, and certification. Testing helps to assure safety, dependability, compliance, and quality control. It is also vital to get professional help in understanding the various testing methods. The following are the many approaches for testing false dead ends.

- Tensile testing – this determines the greatest tensile strength of the false dead end and ensures that it can sustain the specified loads. The procedure entails subjecting the dead end to increasing tensile force until it breaks. This test determines the greatest force that the false dead end can withstand.

- Mechanical load testing – this determines the false dead end’s capacity to withstand static and dynamic loads. The dead end undergoes exposure to forces that imitate the tension generated by conductors and ambient conditions. The tests look for deformations, cracks, and other symptoms of failure under load.

- Fatigue testing – this determines the longevity of false dead ends after many loading and unloading cycles. The dead end undergoes cyclic loading to imitate the stresses faced over its service life.

- Environmental testing – this ensures that the dead ends can endure a variety of environmental conditions. It entails putting the components into environmental rooms that imitate various weather conditions.

- Vibration testing – this test determines the false dead ends’ resilience to vibrations induced by wind or other factors. The approach evaluates its stability and integrity in the presence of oscillatory forces.

- Electrical testing – this takes place to guarantee that the electrical insulating qualities are intact. It entails measuring the electrical resistance and breakdown voltage to cut false dead ends.

Certification and guidelines for false dead ends.

The certification process includes design and manufacturing compliance, testing and assessment, certification issuing, ongoing compliance, and quality assurance. Certification assures that false dead ends can withstand mechanical loads and environmental conditions. They also prove a dedication to high-quality manufacturing and continual improvement. The false dead ends adhere to the following certifications and requirements.

- IEEE standards – this contain guidelines for designing and testing transmission line hardware. They also provide standard test protocols for assessing the thermal performance of solid electrical insulation.

- IEC standards – these specify mechanical and environmental performance evaluations for false dead ends.

- ANSI standards – these include the performance and testing of mechanical connectors.

- ISO standards – these are quality management systems that assure production procedures for false dead ends meet high quality standards.

- ASTM standards – these ensure corrosion resistance for metallic components.

Frequently asked Questions

False dead ends offer advantages such as mechanical stability, better load distribution, higher durability, and operational flexibility.

Performance qualities include strong load bearing capacity, good tension management, directional stability, and mechanical flexibility to absorb dynamic loads.

The dead ends undergo evaluation for tensile strength, mechanical load, fatigue, vibration, and electrical performance.

False dead ends adhere to a variety of certifications, including IEEE, IEC, ANSI, and ISO.