A service grip dead end is a component used to secure and terminate conductor wires at utility poles. It is also known as a dead end grip or a dead end clamp. Its function if to ensure the integrity and stability of the transmission lines. A service grip dead end has various components making up the structure that enhance its performance. It consists of high strength materials to withstand harsh environmental conditions. Its design consists of a helical shape to wrap around the conductor. This helps to provide a secure grip without damaging the wire. The main functions of the service grip dead end are to terminate the conductors, provide mechanical support and ensure there is minimal electrical resistance. Service grip dead ends help in securing the conductors, reducing strain and enhancing safety. They also ensure the secure and reliable termination of conductors for reliability.

Components of a service grip dead end

A service grip dead end ensures both mechanical stability and electrical continuity. It is important to understand the components and their functions. This helps to select the right equipment and ensures the reliability of electrical systems. The following are the main components of the service grip dead end.

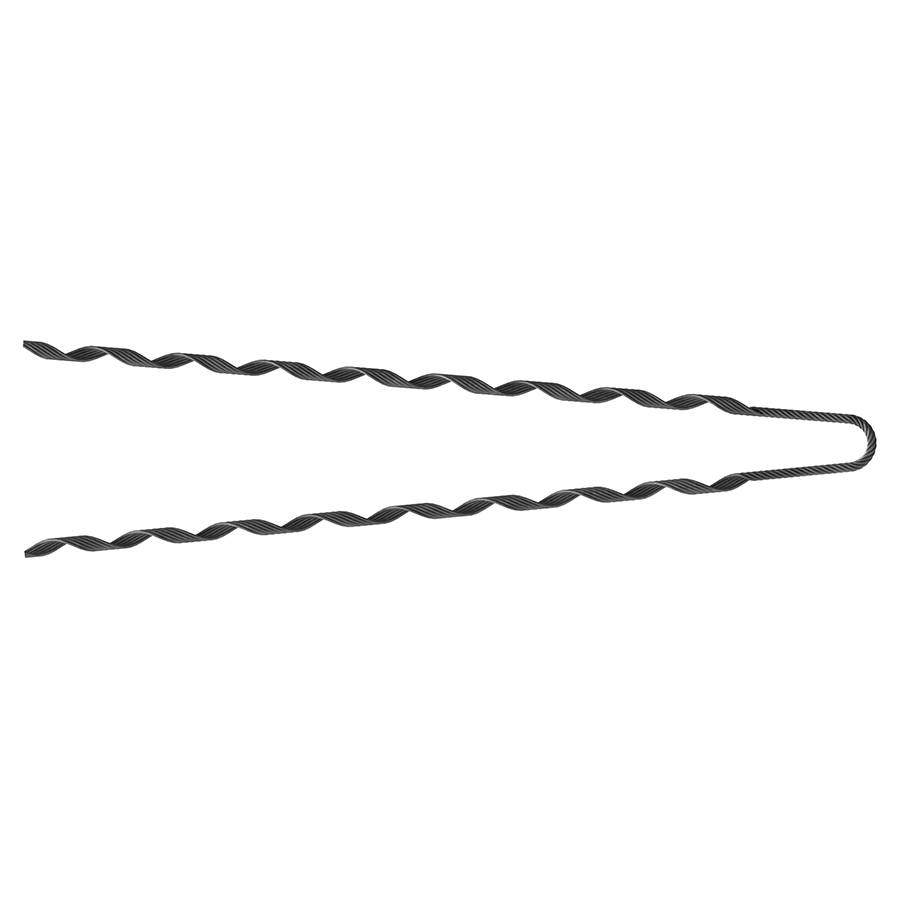

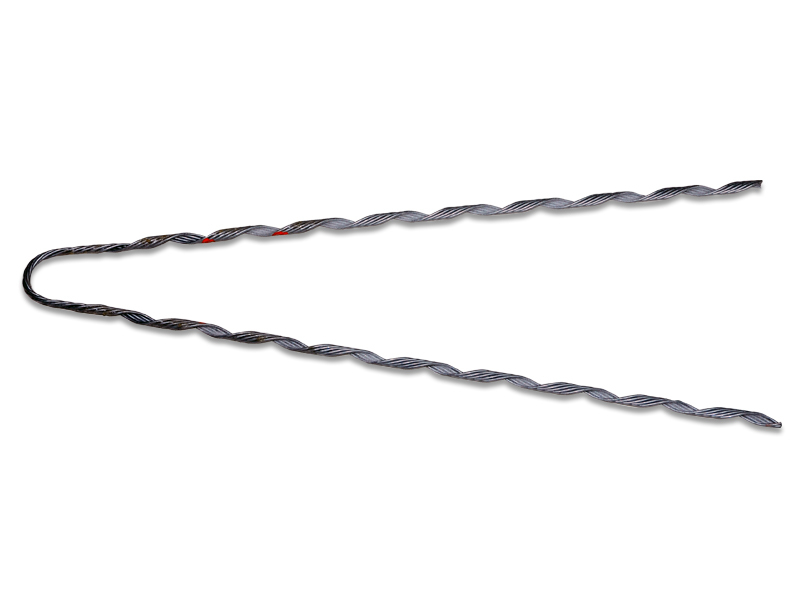

- Helical grip – this is the core component of the service grip dead end. It is from high-strength aluminum-clad steel or galvanized steel. The helical shape wraps around the conductor to provide a secure hold without damaging the wire. The inside of the grip may be smooth or feature serrations to enhance grip strength.

- Thimble – this connects the dead end grip to a stable structure like utility pole. It is from galvanized steel for corrosion resistance and durability. Their main function is to serve as the interface between the grip and the support structure. It helps to transfer the mechanical load from the conductor to the anchor point. Thimbles protect the lop of the grip and to distribute the stress over a larger area.

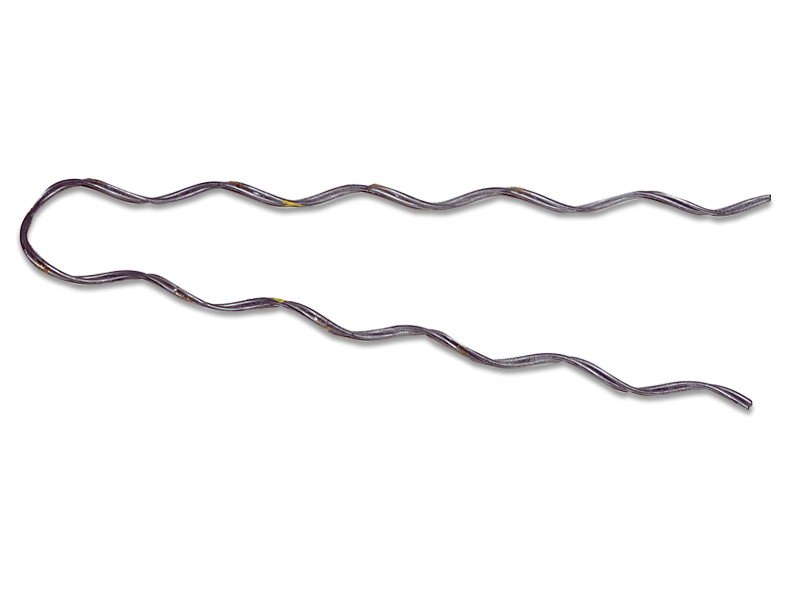

- Armor rods – these are components that wrap around the conductor and provide extra protection and support. They protect the conductor from abrasion and mechanical damage. They work with the main grip to enhance their durability.

- Clevis and yoke plate – these are attachment hardware that connect the grip to the support structure. The clevis provides a secure attachment point to the conductor. The yoke plate distributes the mechanical load across many attachment points.

- Insulators – these are important in maintaining electrical isolation between the conductor and the support structure. They prevent electrical current from passing to the support structures to ensure safety.

Design and structure of service grip dead end

The design and structure of the dead end grip are critical to its function in terminating and securing conductors. It has designs to handle high mechanical loads, ensure electrical continuity and resist environmental stress. Additionally, they help to maintain their integrity and safety of electrical transmission systems. Design considerations include tension and load distribution, electrical continuity, and environmental resistance. The following is a breakdown of its design and structure.

- Preformed grip – this is also known as the helical grip which consists of many strands of high strength wire. It provides a strong mechanical grip on the conductor by wrapping around it and distributing tension along the conductor.

- Dead end body – this is the central component that holds the helical grip and the conductor. It includes attachment points for other components like anchor rods. They act as the primary load-bearing structure ensuring that the conductor stays in place.

- Conductor loop – the end of the conductor has a loop and secured by a helical grip creating a strong termination point. It provides a secure method of terminating the conductor and preventing it from slipping out.

- Thimble – this is a U-shaped component that fits within the conductor loop preventing it from bending. It protects the conductor loop and provides a secure attachment point for the grip to the support structure.

- Compression sleeve – this is a cylindrical metal sleeve crimped around the conductor and the dead end grip. This provides extra mechanical strength and electrical continuity at the termination point.

Industry advancements and updates for the dead end grips

There are various advancements and updates in the design and application of service grip dead ends. They show the ongoing innovations aimed at improving the reliability, efficiency and safety of overhead transmission lines. The developments ensure the service grip dead ends meet the evolving demands of modern electrical infrastructure. Also, staying up to date with the advancements helps to leverage the latest technologies. The following are the newest technologies and updates for service grip dead ends.

- Material innovations – modern service grip dead ends are from advanced aluminum alloys and high-strength steel. This enhances their durability and load-bearing capacity. There is also incorporation of composite materials to improve the strength-to-weight ratio. Development of new corrosion-resistant coatings provides superior protection against rust and environmental degradation.

- Enhanced design features – there are various innovations in the design of the helical grip to improve the distribution of mechanical loads. This reduces the risk of damage and increases the lifespan of the grip and the conductor. Newer designs incorporate vibration dampening elements that reduce the impact of wind-induced vibrations. These features ensure greater stability and longevity of the conductor.

- Smart technologies – the integration of smart sensors and IoT technology enables real-time monitoring of mechanical stress. These provides data that can help in predictive maintenance. This also helps to identify potential issues before leading to failure. New systems feature adaptive tensioning that can adjust the grip on the conductor. This ensures the dead end maintains optimal performance and stability.

- Sustainability – development of service grip dead ends using materials that are easier to recycle. This reduces the environmental impact at the end of the component’s life cycle. The manufacturing processes also improve to reduce emissions, waste and energy consumption.

Voltage rating for service grip dead ends

The voltage rating for service grip dead ends determines their selection and application. The voltage rating determines the insulation requirements, mechanical strength and suitability of the dead end grip. The selected service grip dead end for a particular voltages rating depends on several factors. These include mechanical strength, environmental resistance and insulation and dielectric strength. Advances in materials, design and technology continue to improve the performance and reliability of the dead ends. Additionally, this ensures the safe and efficient power delivery across various voltage levels. The following are the voltage ratings for service grip dead ends in transmission lines.

- Low voltage (LV) – these serve in residential and commercial distribution lines, street lights and services drops. The grips need minimal insulation and have designs for easy installation and removal. They should enhance less emphasis on high mechanical strength. Voltage ranges up to 1kV.

- Medium voltage (MV) – these work in primary distribution lines, industrial power supplies and secondary transmission networks. The grips need moderate insulation, increased mechanical strength and resistance to environmental factors. Voltage ranges between 1kV to 35kV.

- High voltage (HV) – these serve in long distance transmission lines and high capacity distribution systems. The grips need robust insulation to prevent arcing and ensure safe operation. Voltage ranges between 35kV to 230kV.

- Extra high voltage(EHV) – these serve in major transmission networks and cross-country power lines. The grips must have excellent insulation properties and be able to withstand extreme mechanical stresses.

Tensile strength for service grip dead ends

Understanding the tensile strength of a service grip dead end helps to determine their ability to hold and maintain conductor loads. The tensile strength should be enough to handle specific forces from the tension in the lines and weight of the conductor. The following are the factors influencing tensile strength of service grip dead ends.

- Conductor and material type – service grip dead ends may be from materials like aluminum, copper or steel. Aluminum conductors are lightweight but need dead ends with moderate tensile strength. Copper conductors are heavier and stronger and work with grips with higher tensile strength. ACSR conductors combine aluminum with a steel core for added strength.

- Mechanical load and tension – longer spans need grips with greater tensile strength. Consider wind loading, ice accumulation and thermal expansion which can increase the mechanical load on the grip.

- Installation and maintenance – higher tensile strength makes installation more challenging and requires specialized equipment. Dead ends must maintain tensile strength over time.

- Advancements in tensile strength technologies – new alloys offer tensile high strength and corrosion resistance. These enhances durability and performance in harsh environmental conditions.

Frequently asked questions

A service grip dead end is a device used to anchor the end of a conductor in overhead transmission lines. It ensures the mechanical stability and electrical integrity of the lines by gripping the conductor and preventing slippage.

Recent advancements include material innovations, smart technologies, enhanced designs and sustainable practices.

Common materials include galvanized steel, aluminum alloys and composite materials.