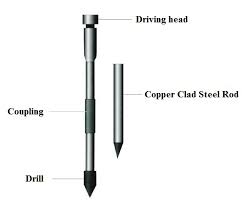

A ground rod coupling is a component used to connect and extend the length of ground rods that are part of the grounding system. Grounding helps to ensure safety, protect equipment and facilitate proper operations. It helps to connect two or more ground rods together in an overhead transmission line. It also provides a reliable and low resistance path to ground for the electrical system. They are from materials such as copper, brass, galvanized steel or other alloys. These materials help to ensure the longer serviceable life in south American applications. The two main types of ground rod couplings include threaded couplings and compression couplings. Other types include non-threaded ground rod coupling, exothermic coupling and high-strength alloy coupling. They find use in various application such as electrical power systems, telecommunication infrastructure, industrial facilities, commercial buildings and transmission lines.

Key features of ground rod coupling

Ground rod couplings have various features that provide a secure and reliable means of connecting couplings. They also help to create an effective path for dissipating fault currents and ensuring safety. The following are key features of ground rod couplings.

- Material and construction – ground rod couplings are from durable and corrosion materials. These include copper, brass, galvanized steel or other alloys.

- Compression mechanism – the compression mechanism helps to secure the connection between ground rods. This provides a strong and reliable bond resistant to loosening.

- Exothermic couplings – they facilitate a molecular bond between the coupling and the ground rod. This is through a welding or exothermic process.

- Galvanizing coating – this helps to provide extra corrosion resistance especially in outdoor installations.

- Threaded design – this design that allows for easy and secure installation to facilitate a tight and stable connection.

- Adjustability – this allows them to accommodate different sizes of ground rods. This feature also enhances versatility making the couplings suitable for various applications.

- Non-threaded options – this feature provides flexibility and are often adjustable to different ground rod sizes.

- High strength alloys – these points allow for visual inspections or attachment of testing equipment. It also helps to assess the integrity of the grounding system over time.

Selection and installation of ground rod coupling

Proper selection of the ground rod couplings helps to ensure the proper performance and longevity of the connection. It includes considering factors such as thread compatibility, material, adjustability, application type, corrosion resistance, inspection and testing, installation ease and costs. The installation should ensure a secure and low-resistance connection between ground rods. The following is a basic installation process of ground rod couplings.

- Preparations – ensure you have all the necessary materials required for the installation. This is including ground rod coupling, ground rods, wrenches or pliers.

- Ground rod coupling inspection – inspect the ground rod coupling for any visible damage or defects. Ensure the threads are in good condition.

- Ground rod preparation – drive the ground rod into the ground using a suitable method such as a ground rod driver.

- Ground rod coupling preparation – ensure the threads are clean and free of debris and ensure it is the open position.

- Thread ground rod coupling – screw the coupling into the threaded end of the ground rod. Use a wrench or pliers to tighten the coupling securely.

- Compression ground rod coupling – position the coupling over the ends of the ground rods. This is to securely fasten the coupling to the ground rods.

- Adjustable ground rod coupling – adjust the coupling to fit the diameter of the ground rod.

- Check for proper alignment – ensure the ground rod coupling is properly aligned with the ground rod. This is to establish a solid a continuous connection.

- Connection inspection – conduct a visual inspection of the installed ground rod coupling. Check for any signs of damage, loose connection or improper alignment.

- Documentation – keep detailed records of the installation. This is including dates, types of ground rod coupling and locations.

Maintenance and inspection of ground rod couplings

Proper maintenance and inspection ensure the continued effectiveness of the grounding system. The diverse environmental conditions in South American influence the frequency of the activity. The following is a basic guide for maintenance and inspection of ground rod coupling in South America.

- Conduct regular visual inspections of the ground rod couplings to check for signs of wear, corrosion or other damage. Ensure the couplings are properly aligned with the ground rods.

- Periodically perform resistance testing to assess the electrical continuity of the grounding system. Measure the resistance between the ground rod and the grounding electrode system. This is through the use appropriate testing equipment.

- Ground rod couplings have inspections points that help in visual inspections and testing for signs of wear or damage.

- Check for loose connection in threaded ground rod couplings to tighten any loose connections. This is to ensure a secure and reliable bond.

- Ensure the ground rod couplings and the entire grounding system to comply with relevant safety standards and regulations. This includes checking the materials used, installation practices and overall system design.

- Assess the condition of the ground rod for signs of corrosion or damage to the ground rods.

- Periodically clean the ground rod couplings to remove dirt, debris and any contaminants. This helps maintain a solid electrical connection.

- Apply corrosion-resistant coatings to the ground rod couplings in areas with high humidity. Regularly inspect for signs of corrosion and address any issues promptly.

- Check the tightness of threaded connections regularly including compression mechanisms.

- Visually inspect the ground rod couplings for any physical damage to maintain the integrity of the grounding system.

- Consider the specific environmental conditions of the installation site where salt exposure is high.

- Maintain detailed documentation of maintenance of activities. This is including dates of inspections any maintenance performed.

Comparative analysis of ground rod couplings in South America

Conducting a comparative analysis for ground rod couplings which involves evaluating various types and brands. These factors help to select the best ground rod couplings for your specific application. Additionally, it is important to consult with professionals for best selection of the ground rod couplings. The following are the factors to include in the comparative analysis in South America.

- Material and corrosion – compare the materials used in different of ground rod couplings. Choose materials like copper, brass, galvanized steel or high-strength alloys.

- Adjustability and compatibility – assess the ground rod couplings are adjustable to accommodate different ground rod sizes.

- Installation ease – compare the ease of installation for different types of ground rod couplings. Consider the user friendliness of the tools to use.

- Costs – compare the costs of different ground rod couplings considering both the initial purchase price and the long-term cost-effectiveness.

- Threaded vs compression design – compare the design of ground rod couplings and their benefits and limitations of each design.

- Adjustability and compatibility – assess the adjustability of the ground rod couplings to accommodate different ground rod sizes.

Certifications and standards in South America

The different standards and certifications help to ensure their safety, performance and reliability in South America. Their also guide the manufacturers and suppliers in documentation and labels for certifications. Additionally, it is important to ensure the selected ground rod coupling meets the relevant industry standards. The following are the common certifications and standards in South America.

- UL certification – this is a global certifications organization for various products including ground rod coupling.

- IEEE standards – this is a standard related to various aspects of electrical systems including grounding.

- NEC standards – this provides requirements for electrical installations and electrical safety.

- IEC standards – this publishes international standards for electrical, electronic and related technologies. It helps for lighting protection system components including grounding components.

- ASTM standards – this is a standard for various materials, products, systems and services. It also includes those related to materials, dimensions and testing procedures.

Regional market for ground rod couplings

There are various conditions that influence the regional market for ground rod coupling in South America. These factors also influence the demand and supply of ground rod coupling in the region. The following are the factors that shape the regional market for ground rod couplings.

- Infrastructure development – the demand for ground rod couplings is also linked to infrastructure development projects.

- Industrial growth – the growth of the industrial sector needs the use of robust grounding systems.

- Upgrades and maintenance – the ongoing upgrades and maintenance of existing infrastructure contributes to the demand for replacement grounding components.

- Telecommunications infrastructure – the expansion of telecommunications networks and the rollout of 5G technology. This contributes to the demand for grounding components in urban areas.

- Renewable energy projects – growth of renewable energy projects contributes to the demand for grounding components like ground rod couplings.

Frequently asked questions

Ground rod couplings help to create a secure and low-resistance connection between ground rods. They play an important role in establishing effective grounding systems, dissipating fault currents and ensuring electrical safety.

The size of the ground rod coupling should match the diameter of the ground rod. Adjustable couplings offer flexibility and can accommodate different ground rod sizes.

Ground rod couplings are integral to grounding systems that provide a path for lightning to safely dissipate into the ground, protecting structures and equipment from damage.