A guy hook is a device used in overhead transmission lines to provide support and anchorage to the guy wires. It acts as an anchor point for the guy wire to provide stability and additional support to the pole. This helps to distribute tension along the guy wire to prevent excessive swaying. Guy hooks are from materials that resist rust and corrosion such as steel or ductile iron for durability. A guy hook has a curved opening that holds the looped end of a guy wire. It is mainly used in areas with high winds or loads where extra support is necessary.

Components of a guy hook

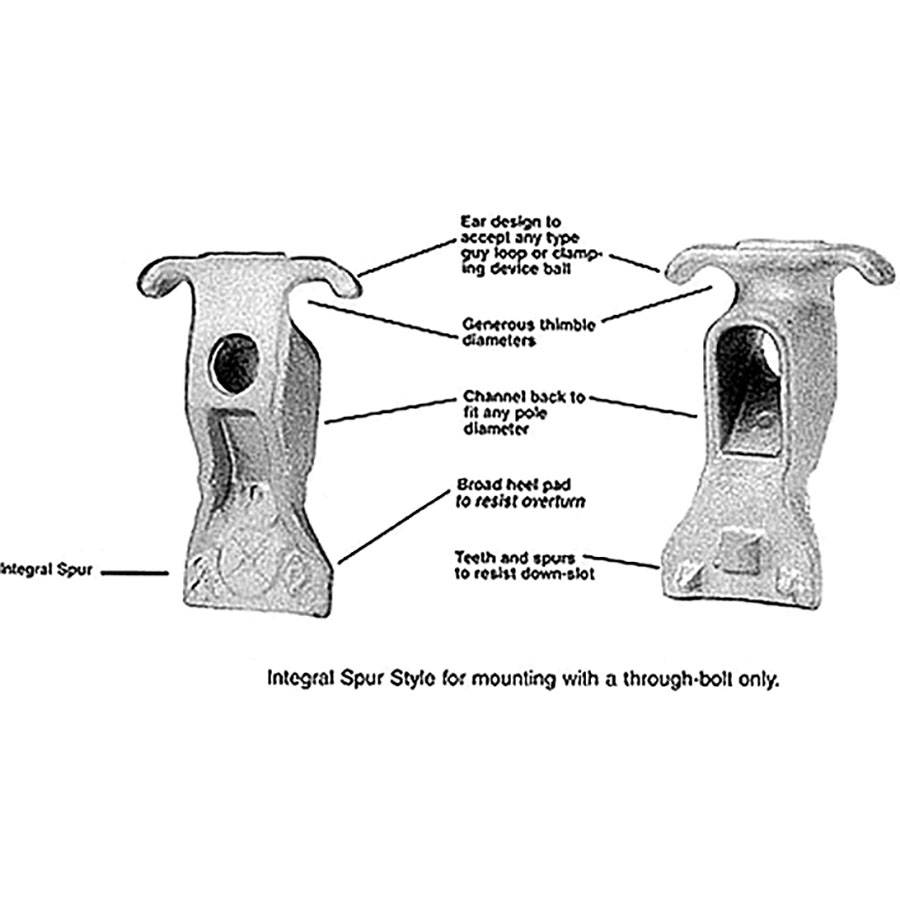

Guy hooks come in different styles and designs with various features such as essential shoots which prevent the guy hook from inserting in the pole. The different components of a guy hooks act together to provide support and anchorage for the guy wires in overhead transmission lines. The components however vary depending on the manufacturer, intended application and regional standards. The following are the key components of guy hooks.

- Shank – this is the main part of the guy hooks making up the body that connects the attachment end of the hook to the anchor end.

- Attachment end – this is the part that attaches to the utility pole or structure. It has a hole that secures the hook in place.

- Anchor end – this is the part where the guy wire connects which features a curved section that holds the guy wire securely.

- Hole – holes in some of the guy hooks provide a point for attaching hardware such as bolts, nuts and washers for secure connections.

- Threaded portion – some of the guy hooks have threaded portions in the shanks that allow for easy attachment of the hook to the utility pole.

Types of guy hooks

Different types of high-load guy hooks support various applications and specific requirements in the overhead power systems. The type also depends on the load requirements and the regional standards and electrical codes available. This helps to meet the specific requirements of the application and enhance reliability and safety of the installation. Below are the common types of guy hooks.

- Straight guy hook – this is the most common type of guy hook that features a straight shank and a curved end. They work for general purpose applications to provide a secure anchor point for guy wires.

- Triple arming guy hook – these support three conductors or arms on a utility pole. They have a long shank and extra reinforcement for increased load-bearing capacity.

- Helical guy hook – these hooks have a helical shape along their shank which helps provide extra gripping power to enhance the hooks holding strength.

- Double arming guy hook – the double design allows them to provide support for multiple conductors or arms for extra load.

- Anchor rod guy hook – these hooks work when attaching guy wires to concrete or anchor rods inserting to the ground.

Applications of guy hooks

Guy hooks find use in various applications in the industry where installation and support of guy wires is essential. The application of the guy hooks depends on the requirements of the project, load considerations and regional regulations. The following are the main applications of the guy hooks.

- Antenna installations – antennas for TV, radio or satellite dishes use guy hooks to anchor and support the guy wires. This ensures proper alignment and stability of the antennas.

- Wind turbines – guy hooks secure and anchor guy wires on wind turbines used in renewable energy production. Guy hooks provide stability and support to the turbine to prevent swaying.

- Construction – guy hooks work in the construction industry for temporary structures such as framework, temporary fences or signage installations.

- Power transmission and distribution – guy hooks work in power utility sector to secure and anchor guy wires to utility poles. Guy hooks provide a reliable anchor point and contribute to the stability of overhead power lines.

- Telecommunication lines – the hooks support guy wires on antenna towers and communication masts to provide stability to the structures.

- Radio and broadcast – guy hooks anchor and support guy wires to ensure stability and proper alignment of tall structures. These are structures used for transmitting radio signals and broadcasting media.

- Marine applications – guy hooks secure and anchor guy wires on offshore platforms, buoys or marine communication systems.

Installation guide for guy hooks

Installation process for the guy hooks provide proper attachment and anchoring of guy wires for different applications. The installation varies depending on the type of guy hook, manufacturer guidelines and any applicable industry standards or regulations. Some manufacturers offer installation instructions to follow to the latter. Additionally, it is advisable to consult with experts in the industry for guidance and assistance during the installation. The following is a basic installation process of the guy hooks.

- Determine the suitable location for installing the guy hook by looking for the anchor point on the utility pole or structure.

- Ensure the anchor point is clean and free from any contaminations that may hinder the installation of the guy hook.

- Mark the exact spot where the guy hook will install on the utility pole using a measuring tape and a marker. Drill the hole at the marked location to facilitate easier installation.

- Align the attachment end of the guy hook with the marked spot on the utility pole. Insert the fasteners through the predrilled holes in the hook and tighten using suitable tools.

- Attach the guy wire to the anchor end of the hook such as wrapping or using suitable hardware.

- Adjust the tension of the guy wire as required to provide the desired level of support and stability. Use the suitable devices such as tensioning rods to achieve the recommended tension level.

- Inspect the installation to check for signs of damage or wear and ensure they are secure.

Selecting the best guy hook

Guy hooks should offer the best combination of performance, reliability and compatibility for your intended application. The selection process involves various factors to consider before purchase. The best guy hook should meet the specific requirements for your application and offer the best support. Additionally, it is advisable to consult manufacturers, suppliers and professionals in the industry for guidance on the best guy hooks. The following are the main factors to consider.

- Ensure the guy hook is compatible with the diameter of the guy wire to use.

- Evaluate the material used for the guy hook which should be durable, corrosion-resistant and capable to withstand different weather conditions.

- Consider the design of the guy hook and the type of attachment it requires and ensure the attachment type is compatible with the utility pole.

- Determine the anticipated load capacity needed to support and ensure the guy hook is suitable for the specific load requirements.

- Verify that the hook complies with relevant industry standards and regulations. This is in regards to design, performance and safety standards for guy hooks.

- Select guy hooks from reputable manufacturers known for producing high quality and reliable products.

- Consider the application intended for the guy hook and ensure they meet the specific requirements.

Frequently asked questions

A guy hook is a device used to support and anchorage for guy wires on overhead transmission lines. it acts as an anchor point for the guy wire to provide stability and support to the pole.

Guy hooks offer various benefits to the overhead power lines to increase support and anchor to guy wires. They include increased structural stability, load distribution, increased safety, easy installation and maintenance, cost effectiveness and enhanced resilience. These factors should help during the selection process of the best guy hooks.

Guy hooks also have various limitations that limit their adoption in various applications. The limitations include anchorage points limitations, requires a certain amount of space, require regular maintenance, aesthetic impact and environmental conditions. These limitations resolve through proper selection, installation and maintenance practices.