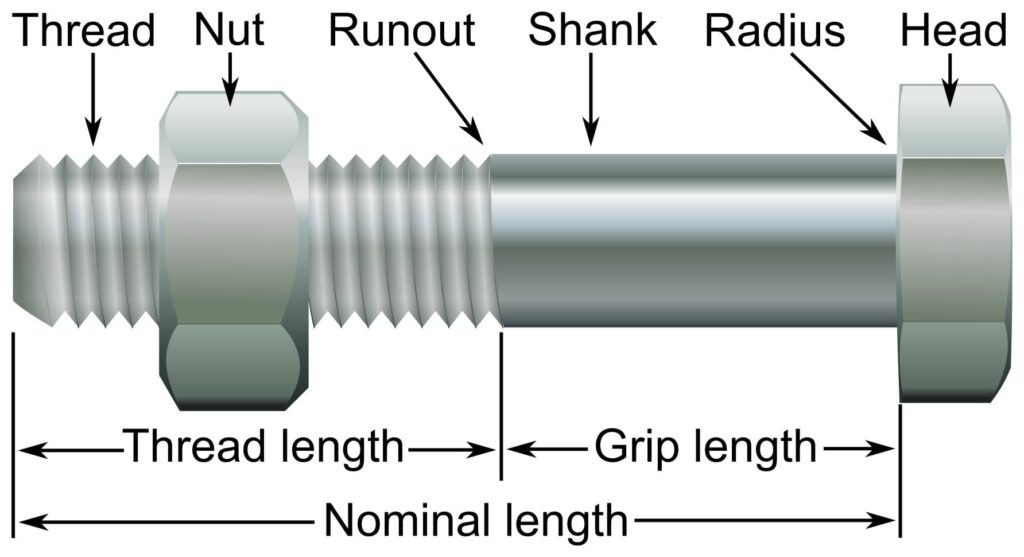

A hex bolt and nut include components used in conjunction with other hardware to secure other components of the system. Hex bolts are bolts with hexagonal heads used with a hexagonal nut. It may have threads that allow for secure connections between various part. Hex bolts and nuts help to secure clamps, connectors, insulators, brackets and crossarms. They are from high strength materials that help ensure they withstand environmental factors. Materials include steel or other alloys for durability and strength. These materials help them to withstand the various environmental conditions of South America. The hex design of the bolt head and nut allows for easier application and removal using common tools. Common examples include tap bolts, structural bolts, flange bolts, standard hex nut, heavy hex nut, wing and flange nuts. They find use in applications such as construction, marine industry, agriculture and telecommunications.

Key features of hex bolt and nut

Hex bolt and nut have various features that ensure the safety and reliability of the installations. These features make the hex bolt and nut crucial components in various applications in South America. They find use in applications where secure fastening and durability is essential. The following are the key features of the hex bolt and nut.

- Strength and durability – hex bolt and nuts have designs to withstand heavy loads and resist shearing. This makes them reliable for various applications.

- Corrosion resistance – they are from materials or coatings that resist rust and corrosion. This helps to enhance their lifespan in various environments.

- Wide application – the fasteners find use in applications such as construction, machinery and automotive. .

- Material – they are from materials like stainless steel, carbon steel and alloy steel. these help to provide options for different environmental conditions and load requirements.

- Versatility – the hex bolt and nuts are available in different sizes, materials and types. This helps to cater to various needs across industries.

- Ease of use – the bolts and nuts allow for easy installation and removal. This is using common tools like wrenches or sockets.

- Thread options – they are also offered in various thread terrains and types. This helps them to work in different applications and materials.

Selection and installation of hex bolt and nut

The selection process involves considering several factors that influence the usability of the hex bolt and nut. These are factors based on the intended use and the specific application requirements. These factors include material, size, length, strength, thread type, type of nut, installation method and coating. The installation follows a guideline to ensure safety and effectiveness of the connections. Additionally, it is advisable to seek professional help whenever in doubt during installation. The following is a step-by-step guideline to install hex bolt and nut.

- Preparations – collect all the suitable types and sizes of the hex bolt and nut required for the application.

- Alignment – place the materials together to ensure they are properly aligned and ready for fastening.

- Hex bolt attachment – insert the hex bolt through the hole in the materials. Ensure the head is on the side where its easily accessible.

- Add the hex nut – thread the hex nut onto the other side of the bolt. Use a washer between the nut and the material for a broader contact surface.

- Hand tightening – hand tighten the nut onto the bolt until cozy against the material.

- Wrench tightening – use a suitable wrench to further tighten the nut onto the bolt. This helps to ensure a secure connection without over tightening.

- Check for alignment – ensure the materials to connect remain aligned without any distortion.

- Quality check – inspect the fastened connection to ensure its secure and in line with the application requirements.

Maintenance and inspection of hex bolt and nut

Regular maintenance and inspection of hex bolts and nuts helps to ensure their functionality. It also helps to ensure the continued safety, reliability and efficiency of the components in the applications. The frequency depends on the environmental conditions in the installation regions. This also helps to identify and address issues that could lead to accidents. The following is a common guide for the maintenance and inspection of hex bolts and nuts.

- Inspect the hex bolts and nuts for signs of wear, damage or corrosion. Check for cracks, deformities or any irregularities on the bolt threads and the nuts surface.

- Check the condition of the threads to ensure they are intact and undamaged.

- Examine the surface for any signs of damage, corrosion or rust. Consider applying anti-corrosion coatings or materials in outdoor applications.

- Check if there is any movement in the connection which might indicate the need for tightening or damage.

- Regularly tighten the hex nuts to ensure they remain securely fastened especially in applications prone to vibrations.

- Keep the bolts and nuts clean to prevent the buildup of debris that might compromise their integrity.

- Periodically conduct load testing to ensure the continued capability of the connection to withstand expected loads.

- Implement a schedule for routine inspection and maintenance to address anu issues promptly.

- Replace anu worn, damaged or weak bolts and nuts to maintain safety of the application.

- Maintain records of inspections including tests and maintenance activities for future reference.

Comparative analysis of hex bots and nuts in South America

A comparative analysis includes assessing and evaluating various factors that influence the usability of the hex bolt and nuts. These factors include types, sizes, lengths, brands, manufacturers and suppliers. These factors also help to ensure the proper selection for the various applications in the industry. Additionally, it is advisable to consult industry professionals for guidance on the best hex bolt and nut. The following are the key factors to include in a comparative analysis.

- Material – compare the materials used for the bolts and nuts and check in strength, corrosion resistance and suitability.

- Size and thread type – compare the available sizes and threading types considering their compatibility with the intended application.

- Industry specific needs – consider the specific requirements of industries in south America such as construction, energy or telecommunications.

- Cost and value – consider the cost of the bolts and nuts in relation to their features, durability and performance. This helps to determine their value for specific applications.

- Load capacity – evaluate the load capacity and strength grades of the bolts and nuts. Ensure they meet the specific requirements of the applications in the region.

- Corrosion resistance – consider the effectiveness of coatings or materials used to resist corrosion in various environments.

- Manufacturer reputation – compare the reputation of suppliers and manufacturers in the market. They should have a record for reliability, quality and customer satisfaction.

Certifications and standards in South America

Hex bolts and nuts comply with various standards and certifications to ensure their safety and quality. There are also other regional regulations and industry specific standards for using hex bolts and nuts. Also, it is advisable to consult with local regulatory bodies within the specific south American countries for a better understanding. The following are the certifications and standards for hex bolts and nuts in South America.

- ABNT – these are technical standards that might cover the specifications for hex bolts and nuts in various industries.

- ISO standards – these are standards for various aspects of manufacturing for fasteners like hex bolts and nuts. They also ensure the quality and performance of the hex bolts and nuts in the various conditions.

- DIN standards – these are German standards for fasteners adopted by various south American countries.

- Industry specific regulations – these are standards set by the various industries in the region. These include construction, energy or transportation.

- Local and national regulations – each south American country has their own set of standards that dictate the quality and safety requirements for industrial equipment.

Regional market for hex bolts and nuts

There are various factors that influence the regional market for hex bolts and nuts in South America. These factors include quality, reliability, compliance with standards and resistance to environmental conditions. The following are the factors that shape the market for hex bolts and nuts.

- Energy and utilities – these fasteners are crucial for power generation, transmission and distribution systems.

- Automotive and transportation – usability of the bolts and nuts in this sector leads to the increased demand for hex bolts and nuts.

- Competition – the availability of manufacturers and suppliers in the region also influence the demand and supply of the fasteners.

- Infrastructure development – expansion and upgrades of electrical grids and infrastructure may lead to increased demand for hex bolts and nuts.

Frequently asked questions

Hex bolts and nuts are components used in conjunction with other hardware to secure various components of the transmission system. They are able to withstand the tension and environmental factors in various regions.

Hex nut wrenches are used to tighten hex nuts and are constructed of industrial grade plastic. The cap rotates freely as it turns.

Hex bolts and nuts find use in applications such as construction, machinery and equipment, automotive, utilities and energy, maritime industry and agriculture.