There are a couple of cycles that follow on manufacturing U-bolts.

Using u-bolt bowing machine, the steel is then cold molded into the genuine shape. When the steel produced and still at its temperature, persuade it through a movement of pressure.

The tooling itself is fair for remarkable. It includes up to 200 distinct pieces with flexibility of hundredths of a millimeter. At the point when consummated, cold manufacturing ensures bolts. They are produced in an even time span, in huge volumes, and with high uniformity.

It requires extra twisting or infiltration for more impressive u-bolt designs. The desingn can not curve with crisp molding alone.

Turning the bolt quickly and cutting steel away to comprehend the predetermined form and style are all part of the turning structure. Exhausting is wont to make openings through the bolt. When necessary, a couple of bolts might also have washers attached at this stage of the procedure.

Heat treatment may be a standard cycle for all bolts. It includes introducing the bolt to outrageous temperatures to cement the steel.

When the steel is softer, hanging before heat treatment, either by rolling or cutting. Moving is like cold manufacturing. It entails sending the bolt through a fail to shape and frame the steel into strings. Cutting the u-bolt includes molding strings by cutting and disposing of steel bits.

The heat treatment tends to affect the characteristics of the steel. They will make it harder. Thus, hanging ahead of time is more direct and fair. Regardless, hanging after heat treatment is a clear result in better fatigue execution.

Cold forging of the U-bolt starts with large steel wire rods. This kind of rods are unfold and have different dimensions. The standard grade of steel for u-bolt manufacturing is across the globe. It is consistent with the requirements of ISO 898‑1.

Table of Contents

- U-Bolt Surface Treatment

- How to Measure U-Bolts

- Factors to Consider When Choosing U-Bolts

- How to install U-Bolts-Step-By Step Guide

- Where to Buy U-Bolt in China: TTF Power

U-Bolt Surface Treatment

On top of those typical focus parts, U-bolt manufacturers can add cautious coatings. These consummations provide higher protection against disintegration. The following are a couple of typical coatings or surface prescriptions for U-bolts:

Zinc Plating

Zinc plating includes adding zinc using a layer of force. Usually a more thin layer turns out better for indoor applications.

Hot-dip galvanization

The Hot-dip galvanization technique in like manner includes adding zinc. The process of adding zinc is more complicated covering. U-Bolt manufacturers dunk the bolt in liquid zinc to make a bond. The liquid makes the covering proper for destructive circumstances. They are suitable for high humidity or salt inside the air.

Fluoropolymer (Xylan, Teflon, or PTFE) Coating for u-bolts

A fluoropolymer covering may be a mixture of parts that are immune to disintegration. The covering can delay in outrageous hot and cold temperatures without breaking.

Thermoplastic Coating

The essential advantage of adding a thermoplastic cover to U-bolts is the extra buffer between metals. Metal-on-metal contact can result in galvanic breakdown and fractured metal structures. A thermoplastic covering is for creating a neutral protective barrier between the line and the limitation.

The choice of U-bolt surface treatment is picked by the U-bolt’s application. To tell the truth, it is the requirements of the customer. Consumption blockage is the most common worry for locks. Thus, a zinc-plated coating applied by electrolytic treatment may be a simple remedy.

How to Measure U-Bolts

How to decide the u-bolts aspects? There are a wide range of approaches to accomplishing this goal. This step is quite crucial. This is because the bolts should be of the right size for whichever application that you will put them to.

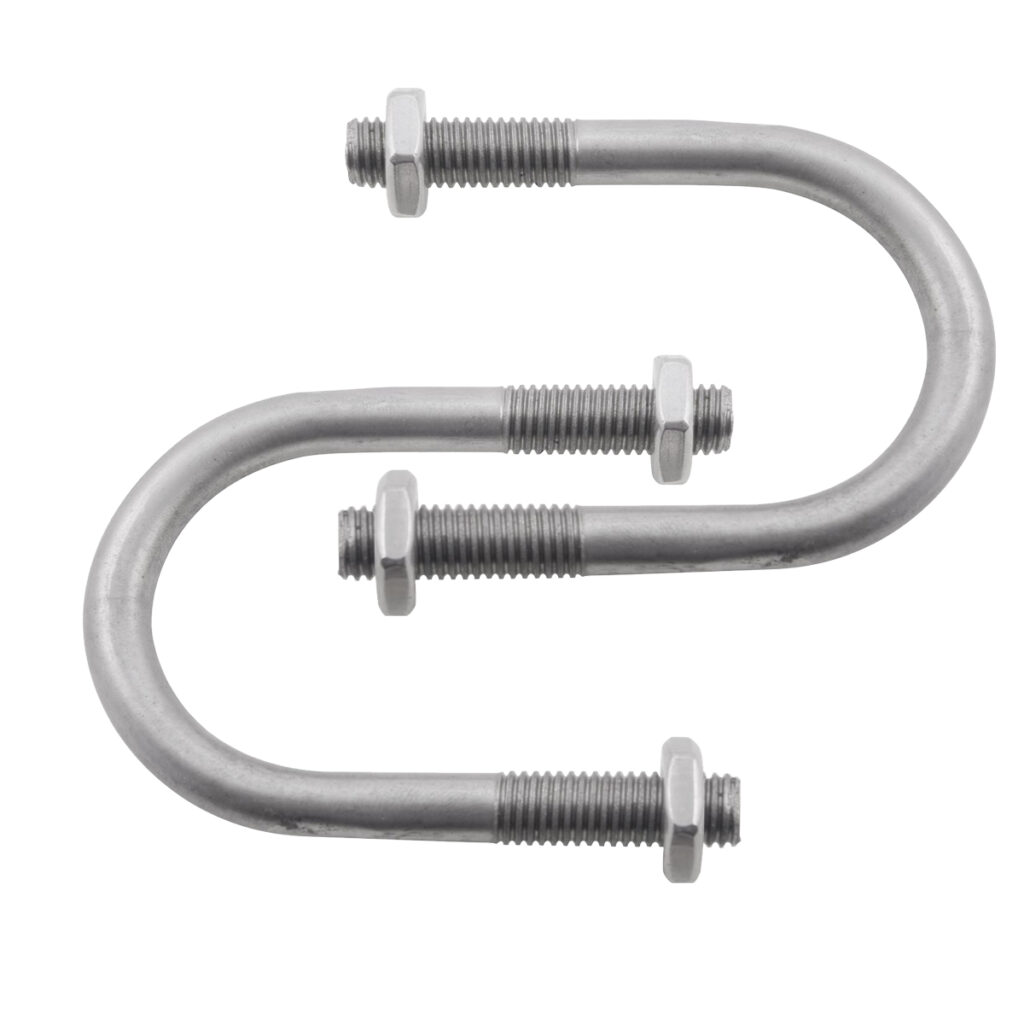

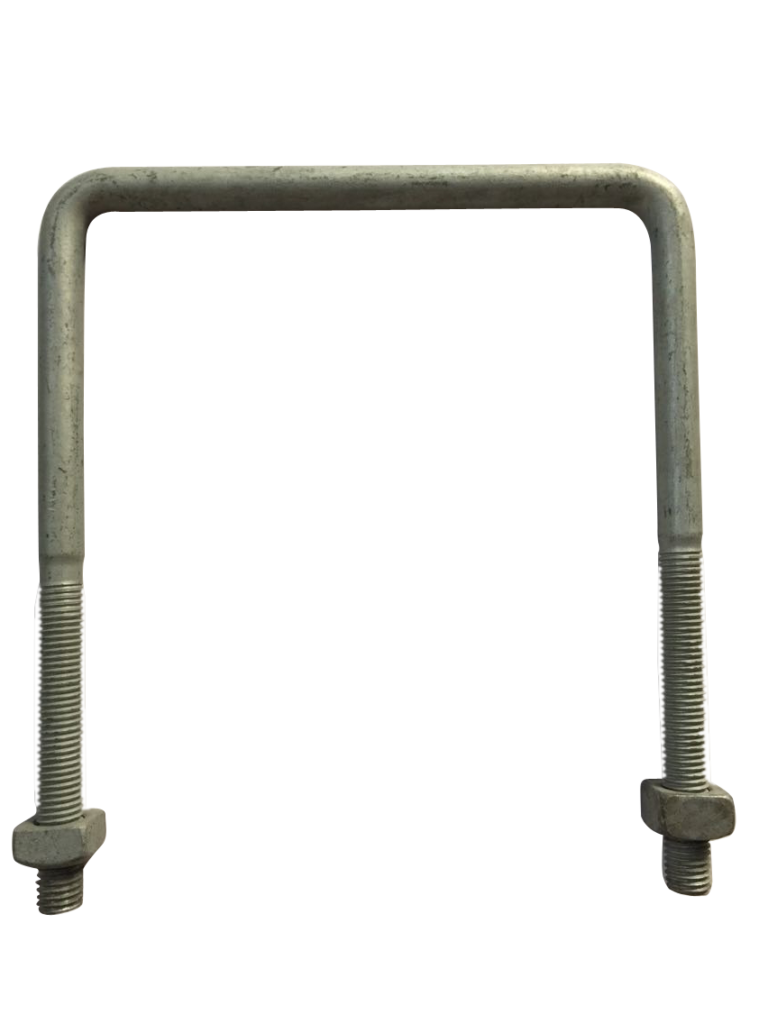

There is no question that the spans of u-bots will generally differ. There are enormous u-bolts while there are little u-bolts at the same time. U-bolts will generally connected with the components of the lines they intend to secure. Bolts can run somewhere in the range of 1/4 of an in. to a full inch in pole size. furthermore, that they can hold channeling as wide as 30 inches.

Factors to Consider When Choosing U-Bolts

Whichever application, here are the key factors that you should consider while buying U-bolts.

The purpose/application:

The primary function of U-bolts is to provide a catching ability to connect two pieces.

U-bolt perspectives:

U-bolts are measured based on string length, inside expansibility, inside level, and string size. U-bolts were at first measured using pipe add planning to talk. As aresult, a U-bolt would at first depicted by the line’s size that it had been supporting.

U-bolts cost:

Like various things, you can’t avoid the issue of cost. U-bolts are humble. Custom valuing is usually coordinated by quantity and quality. Contact the U-bolt manufacturer for clarification about the expense.

Solace:

How helpful is it to use U-bolts? Generally, this alludes to the straightforwardness of using this equipment. U-bolts are not only strong and effective, but they are also available in a variety of materials. They also come in various strength grades to supply adequate fastening force. We must not overlook the fuction of U-bolts. They are quite easy to work with and adaptable enough for a variety of applications and sectors. Similarly, when using U-bolts, there is no waste of material.

Actual definition:

There are several parts portray the U-bolt. They are material sort, bar expansiveness and inside measurement (between the legs). Other two parts are inside length, and string angles.

U-Bolt Finish:

U-bolts have specified fruitsions to better understand the settings. The settings expect to perform. An example is as follow. There is a kind of U-bolt with disintegration safe material. The material is type 316 tempered steel or a hot-plunged mixed steel. We use this kind of material in the humid or damaging condition.

How to install U-Bolts-Step-By Step Guide

-Drop the two nuts from all sides of the U-bolt

-Place the U-bolt around the line you’re connecting. Then string the bolt’s closures through the openings in supptorting pillar or structure.

-String every one of the nuts on each outer finish of the bolt.

-Hand-fix the nuts that are nearest to the support shaft.

-Fix the outer nuts on each finish of the U-bolt and use an influence instrument or torque to fix the nuts.

If yo are using the U-bolt as a guide, confirm with the dispersing to suit its features before tightening nuts.

Where to Buy U-Bolt in China: TTF Power

Searching for the best U-bolts in China? Think about buying from TTF Power. Whether you need leaf spring square u bolts, round u-bolts, or even custom u bolts. We will get them at you at reasonable costs.

You should simply reach us for reasonable u-bolts in China.