An armor grip suspension is a component used to provide mechanical support and secure conductors in place. Armor grip suspension ensures the reliability and efficiency of power transmission networks. It has the ability to support conductors, manage loads and maintain conductor alignment. The main purpose of the grip is to maintain the tension an alignment of transmission conductors to prevent excessive sagging. It is from durable materials that withstand environmental factors and mechanical stresses. They are also able to support the weight of the conductors. They find use in various applications such as high-voltage power lines and grid infrastructure. Common types of the grip include single-rod armor grip, helical armor grip and cushion armor grip. Elevate your transmission infrastructure in Southeast Asian markets using our innovative technology.

Key features of armor grip suspension

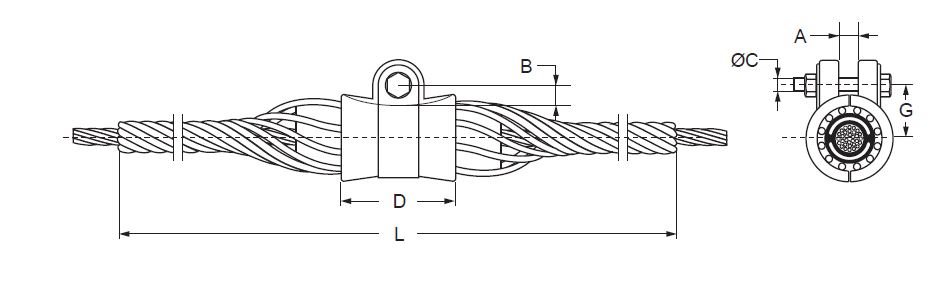

Armor grip suspension consists of several features that enable them to withstand heavy loads. These features also help them reduce vibration and extend lifespan of conductors. This helps improve the overall reliability of overhead transmission lines. This make them vital components in maintaining the stability, efficiency and reliability of lines. The following are the key features of the grips.

- Load distribution – they aid in distributing the mechanical loads and stresses on conductors. This prevents sagging, maintain proper alignment and reduce strain on the conductors.

- Material – the grips are from high-strength materials like aluminum, steel or galvanized steel wires. The materials provide durability, resist corrosion and ensure a long service life.

- Versatility – these grips are versatile as they can hold a range of conductor sizes and types. This makes them suitable for various applications in the industry.

- Weather resistance – the components are typically designed to withstand conditions. These include UV radiation, moisture and temperature fluctuations.

- Adjustability – they also offer adjustability to accommodate different line angles and sag conditions. This helps to ensure proper tension and alignment in the transmission conductors.

- Secure clamping – the clamping mechanism of the suspension holds the conductors in place without damaging it. This helps prevent conductor slippage, vibration or movement due to external factors.

Selection and installation of armor grip suspension

The selection of this component involves considering several factors. They include conductor size and type, load requirements, ease of installation cost and effectiveness. These factors help to ensure the proper functioning and reliability of the transmission network. The installation of armor grip suspension should ensure the secure attachment of conductors. They should also ensure the proper distribution of mechanical loads. The installation procedure depends on the manufacturer’s instruction and the design of the amor grip suspension. The following shows armor grip suspension installation best practices for efficiency.

- Gather the necessary tools and equipment needed for the installation including wrenches, hex keys, torque wrenches, insulating gloves, safety equipment and any specific tools.

- Inspect all the components and ensure they are free from defects, damage or corrosion. Clean and prepare the conductor surface making sure it is free from dirt, debris and any contaminants.

- Determine the suitable location for the suspension along the conductor. Additionally, remember to follow the manufacturer’s recommendations.

- Install the armor rods around the conductor and suspension unit. Ensure they are evenly spaced and provide protection from abrasion.

- Open the clamps of the suspension unit and position them around the conductor.

- Place the fittings onto the suspension unit and make sure they align properly with the tower’s attachment points.

- Tighten the clamps around the conductor using the suitable torque wrench. Also ensure proper grip without damaging the conductor.

- Verify that the conductor is properly aligned and tensioned using suitable tools to measure sag and tension.

- Conduct a visual inspection to ensure all components are properly installed, tightened and aligned.

- Document the installation details including torque settings, measurements and relevant notes.

Maintenance and inspection

Proper maintenance and inspection ensures continued performance, reliability and safety. Maintenance also helps prevent premature wear, degradation and potential failures. Maintenance and inspection also help provide consistent power transmission. It also helps extend the lifespan of the armor grip suspensions. Inspection can be on schedule or regular to check the state of the installations. The maintenance and inspection of armor grip suspension is as discussed below.

Inspection

- Regularly inspect the armor grip suspension for signs of wear, damage or corrosion and check for defects such as cracks, deformation, or loose components.

- Inspect the armor rods to ensure they are securely wound around the conductor and the suspension unit.

- Examine the clamps and grips to verify proper alignment and secure clamping around the conductor. Check for signs of slippage or misalignment.

- Check the fittings that attach the suspension to the tower and ensure they are securely fastened and show no signs of corrosion.

- Measure the sag and tension of the conductor between the suspensions to ensure it observes design specifications.

Maintenance

- Apply appropriate lubricants to moving parts if recommended by manufacturer to reduce friction and wear.

- Apply corrosion-resistant coatings to exposed metal surfaces to prevent rust and degradation.

- Replace the worn or damaged armor rods to increase service life.

- Keep a maintenance log detailing inspection date, findings and any actions taken to keep track of the condition and performance.

Comparative analysis of armor grip suspension

Conducting a comparative analysis process involves assessing different options available in the market based on various factors. It helps to determine their strengths, weaknesses and suitability for specific applications. it also helps you to make an informed decision about the most suitable armor grip suspension for your project. These factors are as detailed below.

- Load bearing capacity – evaluate the maximum load that each suspension can withstand and compare load ratings to determine the most suitable suspension.

- Conductor compatibility – assess the range of conductor sizes and types that each suspension can accommodate.

- Adjustability and flexibility – evaluate whether suspensions offer adjustability for line angles, sag requirements and tension adjustments.

- Installation complexity – compare the ease of installation for each suspension and evaluate whether any specialized tools are required for installation.

- Vibration dampening – evaluate how well each suspension addresses vibration-related issues in areas prone to winds.

- Maintenance requirements – determine the maintenance practice recommended for each suspension. Ensure you compare the frequency of inspections, lubrication and potential replacement of components.

- Environmental resistance – examine how each suspension fares against corrosion, UV radiation and temperature variations.

- Durability – consider the expected lifespan of each suspension and assess the design, materials and potential vulnerabilities.

Certifications and standards

Certifications and standards help to ensure the quality, safety and reliability of armor grip suspensions used in transmission lines. Ensure the chosen product meets the relevant certifications and standards. The following are the relevant certifications and standards associated with armor grip suspensions.

- IEEE standards – the Institute of Electrical and electronics Engineers provide guidelines for the design, testing and installation of overhead line hardware.

- IEC standards – the International Electrotechnical Commission sets international standards for electrical and electronic technologies.

- ASTM standards – this develops and publishes standards for a wide range of materials, products, systems and services.

- ANSI standards – these standards guide the development of reliable, safe and consistent products.

- ISO standards – this sets global standards for various industries and specifies mechanical properties of fasteners made of carbon steel and alloy steel.

Regional market for grip suspension in Southeast Asian countries

The regional market for armor grip suspension in southeast Asian countries is dependent on factors. These factors include increasing energy demand, infrastructure development and need for reliable power transmission systems. Manufacturers and suppliers in this market must be attuned to these dynamics to offer solutions that meet the specific needs of the regions power transmission networks. The following is an overview of the Asian market.

- Southeast Asian countries experience significant economic growth and urbanization which leads to high electricity demand. This drives the expansion and upgrading of power transmission networks which creates demand for armor grip suspensions among other components.

- The use of renewable energy requires armor grip suspension to support the transmission of power generated from these sources.

- Southeast Asian governments are investing in expanding their power transmission infrastructure to connect remote areas. This also helps to support industrial growth and ensure reliable energy supply to urban centers.

- Armor grips suspension help to hold line angles, spans and conditions in areas such as coastal area, mountainous regions and dense forests in Southeast Asia.

- Governments and private entities are investing in energy infrastructure projects to support economic growth. This offers opportunities for manufacturers and suppliers of armor grip suspension.

Frequently asked questions

Armor grip suspension is a mechanical device used in overhead transmission lines to securely clamp and support conductors. They prevent sagging and ensures proper alignment and reliability.

The grips consist of features that help them resist corrosion, UV radiation, temperature fluctuations and other factors.

Armor grips suspension require regular inspections to check for wear, damage and proper alignment. It also depends on factors like environmental conditions and load.