A guy clamp is a hardware used in the construction and maintenance of overhead power lines and utility poles. It has a design that secures and tensions the guy wires to add support to cables for stability of the poles. A guy clamp is also known as a guy wire clamp or a dead-end clamp. It is from durable materials that resist rust and corrosion such as galvanized steel or aluminum. The clamps body consists of grooves used to accommodate the guy wire and hold it in place to allow adjustments and tensioning. High-strength guy clamps find use in various applications such as power transmission and distribution, telecommunications, construction and wind turbines.

Components of guy clamp

The main purpose of the guy clamp is to provide stability, distribute tension, prevent sagging and prevent potential damage to the power lines. It consists of several components of parts that make this achievable. The components vary depending on the manufacturer, load requirements, regional standards and the intended application of the guy clamp. The following are the common components found on a guy clamp.

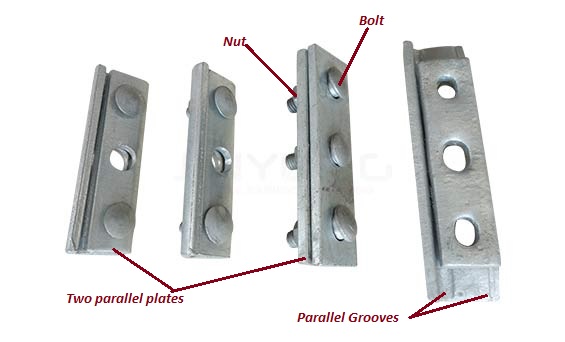

- Body – this is the main component of the guy clamp that provides the structure with stability for longevity. The body has grooves that accommodate the guy wires during construction.

- Grooves – this is the gripping mechanism available to hold the guy wires in place.

- Holes – the clamp has holes or lugs on the sides of the body that provide attachment points for securing the clamp to the utility pole.

- Fasteners – fasteners help to secure the guy wire within the clamp and provide a secure grip on the wire. They include bolts, nuts, washers, screws and clamps.

Types of guy clamps

There are various types, designs and sizes of the guy clamp that help to provide the support and stability required for the installation. The different types and designs meet different specifications and requirements of the application. The selected type of guy clamp depends on factors such as specific application, load requirements, wire diameter and regional standards or regulations. The following are the common types of guy wire clamps.

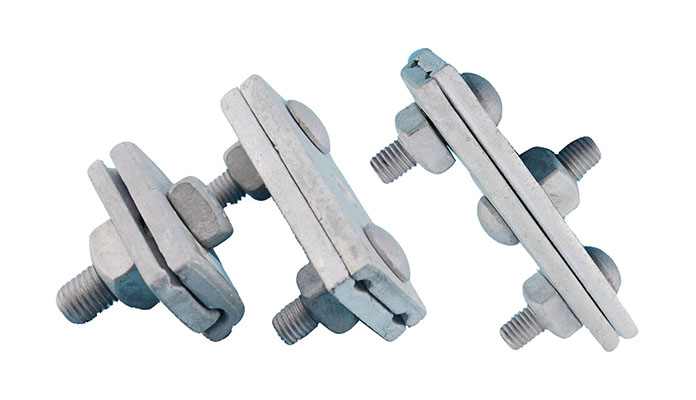

Bolted guy clamp – this clamp utilizes the use of bolts and nuts to secure the guy wire within the clamp.

Wedge guy clamp – this clamp uses a wedge-shaped component that tightens against the guy wire to provide a secure grip. The wedge exerts pressure on the guy wire once tightened to provide a tight and secure connection.

Preformed guy clamps – these have a design that provides a secure grip on the guy wire without using fasteners. The preformed wire allows for easy installation and tensioning.

Compression guy clamps – these use a compression mechanism to secure and tension the guy wire. Th clamp compresses the guy wire once closed to hold in a secure connection.

Automatic guy clamp – these clamps provide automatic tensioning of the guy wire using the built-in feature. They mainly work in areas that require frequent tension adjustments.

Application areas of durable guy clamps

Durable guy clamps find use in various applications that require tensioning and support of the guy wires. The specific application area of a guy clamp depends on requirements of the application, load considerations and regional regulations. The following are the common application areas of guy wire clamps.

- Wind turbines – guy clamps help in construction and maintenance of wind turbines for renewable energy production. Guy clamps support and stability to the turbine tower to maintain integrity and reliability of the structure.

- Construction – the clamps work in the construction industry for temporary structures, fences or signage to provide stability and support to these structures.

- Power transmission and distribution systems – guy clamps provide stability and support to utility poles and overhead power lines. They help the anchors in areas with high wind loads and where vertical stability needs support.

- Street lights – the clamps help secure and tension the guy wires that provide additional stability and prevent swaying of tall structures.

- Telecommunications – guy clamps maintain telecommunication and antenna masts by securing the tension guy wires for extra support.

Installation process of guy clamps

Installation process of the guy clamps aims to meet the specific requirements of the specific application. this helps ensure safe and secure installations during construction and maintenance. Some manufacturers and suppliers may offer instructions for installations or technical support during the installation. The installation process depends on the type of the guy clamp, specific application and regional standards. The following is a basic step by step guide on guy clamp installation.

- Identify the location for installation and ensure it is clear and free from any debris. It should position at an angle for optimal support and stability.

- Prepare the guy wire by cutting to the required length and leave excess for tensioning and adjustments.

- Position the guy clamp onto the guy wire and ensure it aligns with the grooves.

- Insert the free end of the guy wire through the grooves and make sure it seats correctly.

- Tighten the guy clamp around the guy wire using the suitable tools or mechanisms and ensure the clamp grips the guy wire firmly.

- Adjust the position of the guy wire and tense the clamp to achieve the desired tension and maintain a constant tension along the length of the guy wire.

- Inspect the installation and check for damage, loose connections, sagging or excessive swaying. Make the necessary adjustments before documenting the installation process.

Selecting the best guy wire clamp

There are various types and designs of the guy clamp to select from for your particular application. they are also from different manufacturers and suppliers which may have different types and quality. The selected guy clamp should provide best performance, reliability and compatibility of your specific application. The selected clamp also depends on specific application, load requirements, wire diameter and regional standards. The following are the main factors to consider when selecting the guy clamps for your application.

- Consider the expected load capacity or tension that the guy clamp will support. It should be able to handle the expected loads and provide the best support and stability.

- Consider the material used for the guy clamps that offer durability, weather resistance and environmental conditions.

- Evaluate the ease of installation and maintenance for the chosen guy clamps. The clamp should have user-friendly features that simplify the installation and future maintenance tasks.

- Ensure the guy clamps are compatible wit the wire diameter to ensure a proper and secure fit.

- Ensure that the guy clamps comply with the relevant industry standards regarding design, performance and safety standards.

- Consider the reputation and track record of the manufacturer with a record of producing high quality products. Consider the customer reviews, certifications and customer service provided.

Frequently asked questions

This is a hardware used to provide proper support, stability and tension to the guy wires for poles and towers. It is also known as a guy wire clamp or a dead-end clamp.

Guy clamps offer various benefits when it comes to provide support and stability to utility poles. They include secure attachments, enhanced stability, adjustability and tensioning, easy installation, durability and compliance with standards. These factors should help in the selection process of the guy clamps.

Guy clamps also have various limitations to consider and address through proper selection, installation and maintenance practices. They include installation complexity, load capacity, require maintenance, limited compatibility, environmental limitations and compliance with standards.