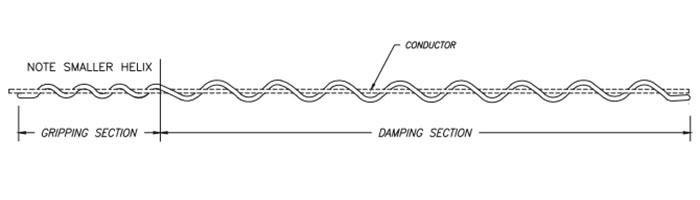

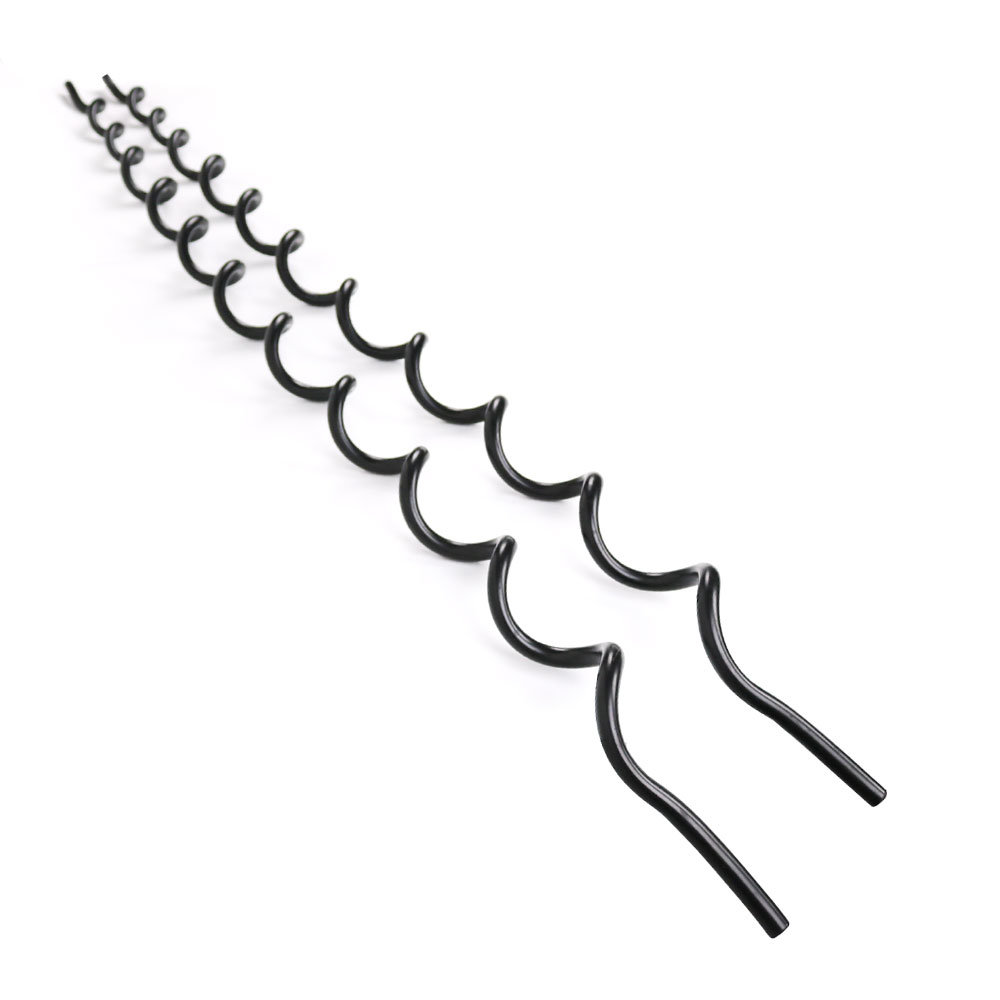

A spiral vibration damper is a mechanical device used to reduce the amplitude of vibrations. These vibrations can affect conductors due to wind-induced motion. It is also known as spiral vibration isolator or simply a vibration damper. The damper helps to ease fatigue and stress on the conductors. It also enhances the complete longevity and reliability of the transmission line. Spiral vibration damper consists of a helical or spiral-shaped metallic or composite structure. Common types of spiral vibration damper include the modified helical dampers, helical spring dampers hybrid dampers and vortex shedding dampers. They find use in various applications such as transmission lines, renewable energy projects, long spans and conductor spans.

Key features of spiral vibration dampers

Spiral vibration dampers consist of several features that help to ease the fatigues on the conductors. The reduction of wind-induced vibrations enhances the longevity and reliability of the system. The following are the key features of the spiral vibration dampers that make them a valuable component.

- Helical design – the helical shape interacts with the wind to disrupt the vortex shedding responsible for conductor vibrations.

- Material – they are from durable materials, corrosion resistant and suitable for outdoor environments. These materials include stainless steel or advanced composite materials.

- Vibration suppression – they suppress aeolian vibrations and prevent excessive oscillations of conductors.

- Installation – they attach at regular intervals along the conductor’s span. This is because they can easily clamp or fastened to conductions.

- Fatigue reduction – they also reduce the fatigue and stress that can lead to premature conductor failure.

- Maintenance – they require minimal maintenance and regular inspection. This is to ensure proper attachment and functionality.

- Safety – the reduced excessive conductor movement contribute to the safety of the transmission lines.

- Cost – the dampers are cost effective and enhance the reliability of transmission lines. This is by reducing the need for frequent repairs.

Selection and Installation of spiral vibration dampers

Selection process of the spiral vibration dampers ensures optimal performance and reliability. This process involves considering several factors that affect the dampers. Additionally, it is advisable to consult with industry professionals for guidance on the selection process. These factors include application challenges, manufacturer specifications, suppression characteristics, simulation and analysis and cost effectiveness among others. The installation requires proper planning, attention to detail and adherence to safety guidelines. The following is a basic process of the installation for spiral vibration dampers.

- Conductor inspection – inspect the conductors to ensure they are free from defects and damage that could affect the attachment of dampers.

- Identify location – determine the optimal locations for attaching the dampers along the conductor spans. Consider wind conditions, conductor tensions and frequency attachment.

- Preparation and layout – lay out the necessary dampers and associated hardware at the desired location. Ensure you have all the required tools and materials.

- Clamp attachment – open the clamp of the damper and carefully position it around the conductor at the attachment point. The dampers’ helical structure should align with the anticipated wind direction.

- Fastening – use suitable tools to fasten the damper securely around the conductor following the recommended torque specifications.

- Torque verification – verify the torque of fasteners using a torque wrench to ensure they are properly tightened. Ensure not to over-tighten or under-tighten.

- Inspection – conduct a thorough visual inspection of each installed damper. This is to ensure proper attachment and alignment.

- Documentation – maintain detailed documentation of the installation process. This is including the locations, torque values and any observations.

Maintenance and inspection of spiral vibration damper

The dampers require regular maintenance and inspection to ensure their effectiveness. They also help maintain the reliability of the overhead transmission lines. Also, ensure to involve experts for more in-depth inspections and assessments. The following is a basic maintenance and inspection of spiral vibration dampers.

- Regularly inspect the dampers for any signs of damage, wear or corrosion. Check for bent of deformed helical structures and loose fasteners.

- Check the attachment of dampers to the conductors and ensure they are securely fastened and aligned with the wind direction.

- Assess the condition of the conductors near the dampers and look for signs of wear, abrasion and fatigue that may affect performance.

- Consider the environmental conditions such as salt exposure, humidity and UV radiation.

- Regularly clean the dampers to remove dirt, debris and environmental contaminants that impact their performance.

- Apply suitable corrosion protection measures such as coatings or treatments. This is to ensure longevity of the dampers.

- Verify the torque of fasteners on the dampers to ensure they remain tight.

- Replace any dampers that show signs of damage to maintain the effectiveness of the vibration dampening systems.

- Maintain detailed records of inspections, maintenance activities and any observations.

Comparative analysis in Southeast Asia

A comparative analysis of the spiral vibration dampers includes evaluating factors that impact their performance and suitability. This helps to create an analysis that guides the selection of spiral vibration dampers. This is helpful due to the specific environmental conditions of Southeast Asian countries. This also helps to find the right type of spiral vibration dampers in the diverse markets for a specific type of application. the following are the key factors to involve in the comparative analysis.

- Environmental conditions – consider the environmental factors in Southeast Asia. These include humidity, salt exposure, temperature variations and wind patterns.

- Materials and corrosion resistance – compare the materials used in spiral vibration dampers and their corrosion resistance capabilities. Examine the best materials suited for those particular humid and coastal conditions.

- Manufacturer reputation – evaluate the reputation of the manufacturer. They should have a track record of producing dampers that perform well in challenging environments.

- Compliance with standards – ensure the dampers comply with the relevant international standards for vibration suppression devices.

- Damping effectiveness – analyze the effectiveness of the dampers in reducing conductor vibrations under varying conditions.

- Customization options – assess the customization options to tailor damper designs to southeast Asian conditions.

- Installation and maintenance – evaluate the ease of installation and maintenance requirements for different damper types.

- Durability – consider the expected lifespan of dampers. Factor the corrosion rates and material degradation.

- Cost – compare the costs of dampers including upfront expenses, installation and maintenance.

Certifications and standards in Southeast Asia

There are various international and regional standards in Southeast Asia. These standards include guidelines and specifications related to the dampers. Consider the manufacturer’s claims, consultation, documentation and testing. This is to assess the performance of dampers under the Southeast Asian countries. The following are the common certifications and standards available in Southeast Asia.

- International Electrotechnical commission (IEC) – these standards mainly provide guidelines for wind turbine generator systems and lightning protection.

- American National Standards Institute (ANSI) – they provide standards and guidelines for nonceramic insulators for overhead lines.

- Institute of Electrical and Electronics Engineers (IEEE) – they provide guidelines for installation of overhead transmission line conductors.

- ASTM international – this helps to evaluate the corrosion resistance of materials. This is important for dampers in humid and coastal environments.

- Local and national standards – the countries in these regions have their own regulations and standards.

Regional market for spiral vibration damper in Southeast Asia

There are various factors that influence the regional market for spiral vibration damper in Southeast Asia. These include rapid economic growth, urbanization, energy demands and need for enhanced reliability. It also depends on the need for reliable power transmission infrastructure. They should withstand the challenges posed by the environment. The governments and private sectors continue to invest in energy and infrastructure project. This leads to increased demand of spiral vibration dampers for longevity. The following are the market trends that influence the market for spiral vibration dampers.

- Infrastructure development – the significant infrastructure development includes the expansion and modernization of power transmission networks. This creates the opportunities for the installation of vibration dampers. This is to enhance the stability and reliability of the transmission lines.

- Renewable energy growth – the increased adoption of renewable energy sources in Southeast Asia demands the robust transmission systems. This includes the need for spiral vibration dampers to ensure the performance of the transmission lines.

- Urbanization and grid expansion – urbanization in this region drives the demand for power supply and transmission infrastructure.

- Coastal and humid environments – the countries have the coastal and humid climate. These conditions poses challenges of corrosion and vibration due to wind. The dampers can help to address these challenges and prevent conductor fatigue

- Market players – the market includes established manufacturers with a global presence. This caters to specific southeast Asian countries. The increase in competition among the players drives innovation for various product options.

Frequently asked question

This is a device used to reduce wind-induced vibrations in conductors in overhead transmission lines. it features a helical-shaped structure that disrupts vortex shedding and mitigating conductor oscillations.

Spiral vibration dampers include extended conductor lifespan, enhanced reliability and reduced downtime. It also improves safety by preventing conductor failures on the overhead transmission lines.

Spiral vibration dampers ensure the stability of transmission lines connected to wind and solar power sources. This helps to enhance the overall grid reliability.