A pole top pin is a device used on overhead power transmission lines and distribution systems. They help to securely attach insulators to utility poles. They are also known as pole top insulator or insulator pin. Pole top pin are from non-conductive materials such as porcelain or polymer materials to provide electrical insulation. It also helps to support and hold the insulator to prevent electrical current from flowing to the unwanted areas. It consists of a threaded shaft inserted into a hole on the side of the utility pole. The threads allow for secure attachment of the conductors.

Components of pole top pin

The available components of an insulator pin work together to provide support and security to the overhead installations. The design and components of a pole top pin vary depending on various factors. These factors include manufacturer of the pin, insulator type and specific installation requirements. The following are the main components found on an insulator pin.

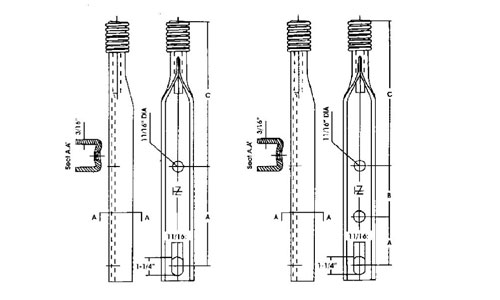

- Shaft – this is the main body of the pin made in a cylindrical shape and non-conductive materials. They help to provide electrical insulation and mechanical strength.

- Threaded end – this part is for attaching the pin to the utility pole to secure fastening to the pole.

- Head – this is the uppermost part that holds the insulator in place. It can have various shapes and sizes depending on the type of insulator to support.

- Insulator groove – this is on the head of the pin that holds the insulator securely.

- Fasteners – nuts, bolts, washers and screws are fastening mechanisms. They help to secure the pole top pin to the utility pole and ensure a stable and secure attachment.

Types of pin insulators

There are various types of pole top pins designed to hold different insulator pins on the power transmission systems. Other factors influencing the type include voltage ratings and installation requirements. Additionally, it is advisable to consult with professionals on what type to use in your project. The common types of pin type insulators are as discussed below.

Tie-top pin – these pins have an extended loop that provides an extra attachment point for overhead conductors.

Offset pin – this pin is typically bent in the shaft which allows the insulator to position slightly away from the utility pole. This provides extra clearance for conductors.

Angle pin – these have an angled shaft that allows the insulator to mount at an angle to the pole.

Suspension pin – suspension pins have a longer shaft and a longer head to hold multiple insulators n a vertical configuration.

Vise-top pin – these pins have a unique head design with jaws that securely grip the insulator. This grip provides enhanced mechanical strength and reduces the risk of slipping or rotating.

Straight shank pin – this pin has a cylindrical shaft with a threaded end and a head for holding the insulator. These are suitable for standard insulator installations and distribution systems.

Guy wire attachment – this pin helps in attaching guy wires which provides extra support and stability to utility poles.

Application areas of pole top pin

Pole top pins find applications in various industries such as power transmission and distribution systems. They ease the secure attachment of insulators, conductors and hardware to utility poles. They also ensure efficient and reliable delivery of electrical power. The following are the common applications of the pole top pins.

Street lighting – pole top pins provide an attachment point for insulators that hold lighting fittings. They also allow for the secure installation of streetlights on utility poles.

Overhead power lines – pole top adapters work in transmission and distribution systems to support insulator strings. They also provide insulation and mechanical stability to conductors.

Insulator attachment – the main function of the pins is to securely attach insulators to utility poles. They provide electrical insulation between conductors and prevent leakage of electrical current.

Tap connections – the pins provide a reliable attachment point for jumper connections. This allow branching off the main line to supply power to secondary distribution systems.

Substations – attachment of circuit breakers, disconnect switches an instrument transformer use pole top pins to securely hold.

Installation process of pole top pins

Installation process of the pole top pin on the different applications depend on the type of pole top pin, insulator and utility pole design. Some manufacturers and suppliers offer after sales services and instructions on the installation of the device. It is advisable to consult professionals and qualified electricians for the installation process to ensure safety protocols. The following are the basic steps involved in the installation of the pole top adapter.

- Ensure the utility pole is in free from debris and contaminants that may affect the installation of the pole top pin.

- Select the location to install the pole top pin and consider factors such as clearance requirements and desired height of the pin.

- Mark the precise point on the pole to attach the top pin and make sure the markings are clear and visible.

- Drill in the marked position using the appropriate tools and ensure the correct size and depth to hold the pole top pin.

- Insert the pole top pin into the hole and apply firm pressure to ensure a secure fit.

- Fasten the pin using the suitable fastening mechanism to secure the pin tightly to the utility pole and to reduce movement.

- Attach the insulator aligning it with any grooves or recessed areas designed to hold it in place. The insulator should seat properly and securely locked onto the pole top pin.

- Inspect the installation to ensure that all connections and installations are properly installed

Selecting the best pole top pin

Choosing the right pole top adapter varies depending on factors such as type of application, pole top pin size and design and safety of the devices. Additionally, consulting with experts helps to select the best pin for your specific requirements of the project. The following are the key factors to consider when the pole top pin for your application.

- Determine the type of insulator to use in the application and consider size, shape and attachment requirements of the insulator.

- Consider the voltage rating of the power transmission or distribution system to provide mechanical strength against electrical stresses and mechanical loads.

- Evaluate the environmental conditions in the installation areas by considering factors like temperature variations, humidity, exposure to UV radiation and chemical exposure.

- Consider the material and the advantages and disadvantages of each. Choose one that suits the specific requirements of the application.

- Check the mechanical load requirements of the installation by considering factors like weight of the insulator, conductors and any additional hardware to attach to the pole top pin.

- Check for specific regulations, standards or requirements set by utility companies. Ensure the selected pin complies to the regulations.

- Ensure the selected pin is compatible with the utility pole and consider factors like size, diameter, hole size and threading requirements.

Frequently Asked Questions

A pole top pin is a long, cylindrical piece of metal with a threaded end that screws into the pole. They help to provide a secure and stable attachment point for insulator pins. They also make it easier for installation and maintenance of insulator pins.

Overhead power lines

Tap connections

Guy wire attachment

Substation equipment

Street lighting

Telephone lines

Provides secure attachment

Electrical insulation

Mechanical strength

Versatility

Durability

Ease of installation

Cost effective

Compliance with industry

Voltage limitations

Environmental factors

Material limitations

Complex installation

Compatibility issues

Limited adjustability

Load capacity limitations