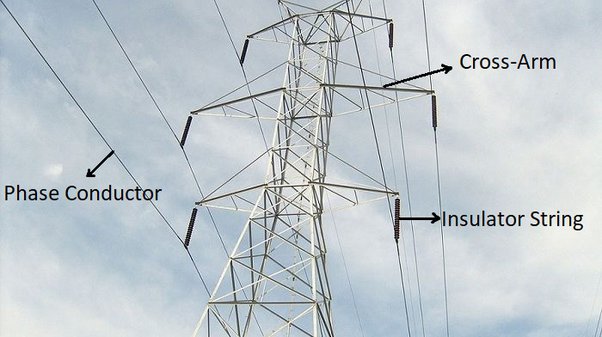

An electrical crossarm is a device also known as a crossarm or a crossarm brace used in the construction of overhead transmission lines. An electrical crossarm is mainly made from wood, fiberglass or steel. It serves as support for the electrical conductors and provides a stable platform for attaching insulators. An electrical crossarm helps maintain the proper spacing and separation between the conductors. This prevents them from touching each other. When the crossarms touch each other frequently, it results in electrical faults or short circuits. They work in areas like power line applications, telecommunication lines, substations and railway electrification. The size, material, design and configuration of the crossarm depend on the voltage and requirements of the transmission line.

Components of the electrical crossarm

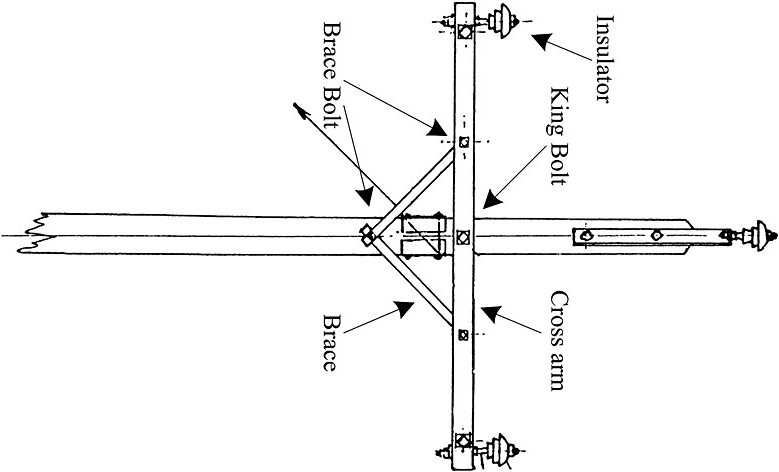

The components of the crossarms work together to support the conductors, maintain proper spacing and provide electrical insulation. This ensures the integrity of the transmission lines sustains. They also help enhance easy installation and maintenance or repairs. The main components of the electrical crossarm are as discussed below.

- Crossarm – this is the main component that is horizontal usually made of wood, fiberglass or steel. It provides support for the conductors since it has a design that is able to withstand the mechanical stresses. This inscludes stress from the weight of the conductors and environmental factors.

- Brace arms – these are diagonal members attached to the main crossarm to provide extra stability and strength. They install in an” X” or “V” configuration extending from the main crossarm towards the pole.

- Insulator – insulators provide electrical insulation and prevents the flow of electricity from the conductors to the crossarm or supporting structure.

- Hardware – different hardware works to secure and connect the crossarm to the pole and attach extra equipment. They include bolts, nuts, washers and clamps which ensure the stability and integrity of the crossarm assembly.

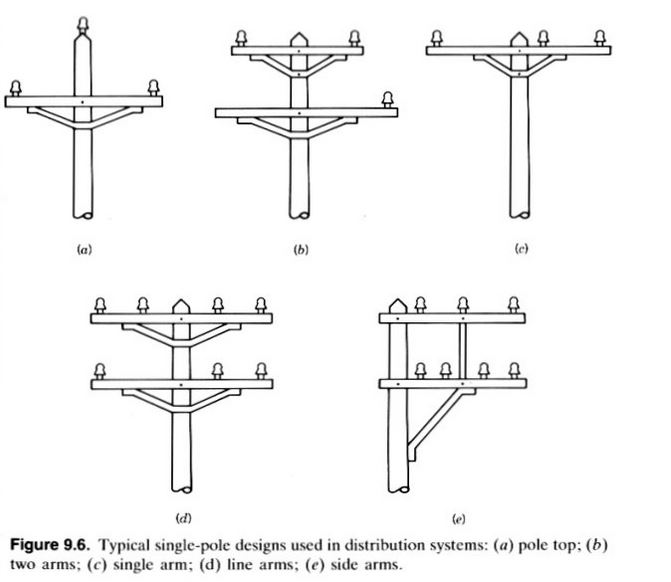

Types of crossarm for overhead transmission lines

There are various types of electrical crossarms that vary depending on material, design and configuration. The choice of the crossarm also depends on voltage rating, requirements, availability of materials and specific project requirements. The following are the common types of crossarm braces based on the material used.

Wooden crossarms – wooden crossarms are from hardwood to offer good strength, durability and electrical insulation properties. They are however vulnerable to decay, insect damage and require maintenance.

Steel crossarms – steel crossarms are from galvanized or coated steel for high strength and durability. They work in areas that need increased mechanical strength. They are resistant to corrosion and provide excellent load baring capacity.

Fabricate steel crossarms – these are custom designed steel structure made for use in heavy-duty applications. Fabrication is through welding and shaping steel plates and beams. This helps to create the desired crossarm configuration.

Fiberglass crossarms – these are from composite materials to offer exceptional resistance to environmental factors. These factors include decay, insects and weathering.

Composite crossarms – these are from a combination of materials such as fiberglass and a thermoplastic resin. Thermoplastic resin are materials that soften to liquid in high heat and harden when cooled. They are lightweight and offer durable alternatives to traditional wooden crossarms. They also provide good strength, resistance to environmental factors.

Applications of electrical crossarms

The main purpose of the crossarms is to support the conductors and ensure the safe and efficient operation of the power system. They facilitate the reliable and safe delivery of electricity and communication services. The following are the key application areas of the crossarms.

Power transmission lines – crossarms work in high-voltage power transmission lines to support the overhead conductors. This provides a stable platform for attaching insulators, maintaining the required conductor spacing and prevent the conductors from contacting each other.

Substations – crossarms work within electrical substations which regulate the flow of electricity. They support busbars, insulators and other equipment within the substation. This provides a stable structure for the installation of various substation components.

Railway electrification – crossarms support the overhead catenary system that provides power to electric trains. They also maintain the stability and proper positioning of the catenary system. The use of crossarms enable efficient rail operations.

Distribution lines – crossarms work in electrical distribution lines to deliver power to homes and businesses. Additionally, they provide support for the lower voltage conductors used in distribution systems. This ensures reliable and safe electricity delivery to consumers.

Telecommunication lines – crossarms support communication cables, fiber optic lines and other media used for voice, data and internet services.

Installation guide for electrical crossarm

Best practices for installing crossarms in high-voltage transmission lines depend on various factors. These factors include type of crossarm, transmission line design and the equipment used. You should follow the manufacturer’s guidelines for safe and secure installations. Additionally, it is advisable to consult with qualified personnel for guidance in installation. The following are the basic steps involved in the installation process of the crossarms.

- Prepare the necessary equipment and materials. They may include insulator pins, crossarms and anyextral hardware.

- Follow safety precautions measures such as wearing protective equipment and following guidelines.

- Position the crossarm on top of the utility pole. The size and type selected bases on the design specifications and voltage rating.

- Secure the crossarm using bolts, brackets or other hardware to tighten the connection. Also, ensure a secure and stable attachment.

- Insert the insulator pins into the pre-drilled holes. This provides a mounting point for the insulators.

- Attach the insulators on the insulator pins and secure the connection. This will ensure proper alignment and electrical insulation.

- Attach the brace arms on the crossarms to provide extra stability in an “X” or “V” configuration.

- Inspect the installations to ensure that the crossarm, insulators and other components installed properly to meet the required standards.

Selecting the best electrical crossarms

The selected electrical crossarm should ensure reliability, safety and cost-effectiveness of your project. There are various factors to consider when selecting the best electrical crossarms. You should also consult with qualified experts in the industry for advice on the best crossarms based on the requirements of the project. The following are the key factors to consider in the selection process.

- Regulate the voltage rating and load capacity requirements of the transmission lines. They should be able to withstand the mechanical stresses forced by the weight of the conductors and environmental factors.

- Assess the advantages and disadvantages of the materials used to make the crossarms. Consider factors like durability, resistance to decay, insects, weathering and fire resistance.

- Test the environmental conditions in the installation area and inspect the climate, temperature variations, moisture levels and exposure to chemicals or pollutant. The selected crossarm should withstand these conditions without degradation or loss of performance.

- Consider the expected service life of the crossarms and the level of maintenance. Balance the upfront costs with long-term maintenance requirements.

- Ensure the selected crossarm is compatible with the existing infrastructure. This includes the pole design, insulators and other associated hardware.

- Verify that the chosen crossarm meets the relevant standards, codes and regulations. This is to ensure the reliability and safety of the transmission line.

- Consider the reputation of the manufacturer who should have a track record of producing high quality products.

- Check the cost of the crossarm by considering upfront costs and long-term expenses. It should promote durability and maintenance requirements.

Frequently Asked Questions

A crossarm is a device used for pole line technologies to support power lines and other electric equipment. They provide a platform for supporting power lines, transformers and other electrical equipment.

Support power lines

Allow expansion of the electrical grid

Protect power lines

Mechanical support

Load distribution

Electrical insulation

Durability

Cost effective

Safety development

Installation complexities

Requires regular maintenance

Susceptible to fire hazards

Limited conductor capacity

Weight and load restrictions

Environmental compatibility