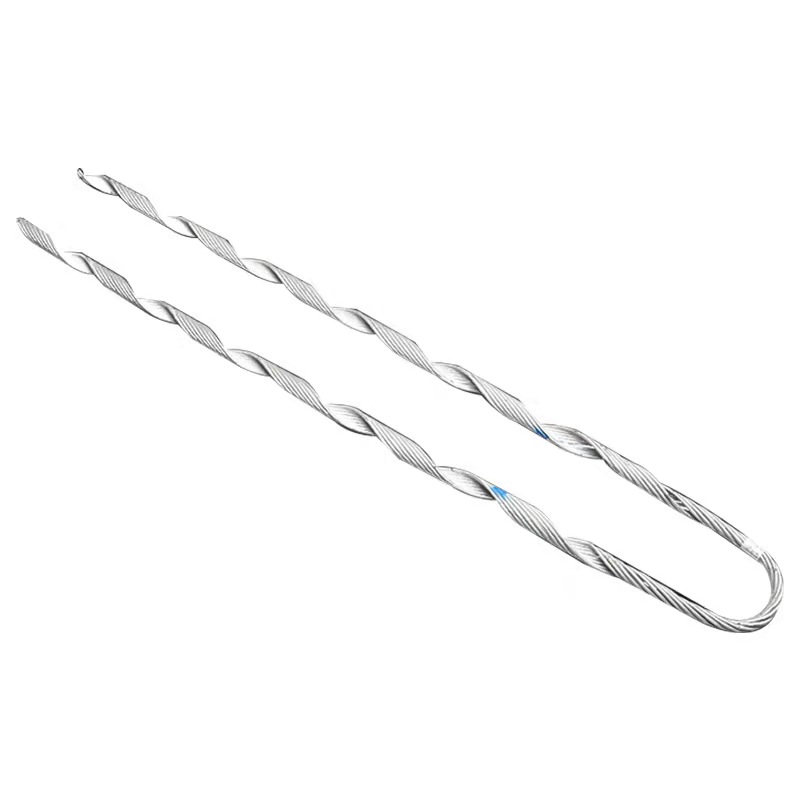

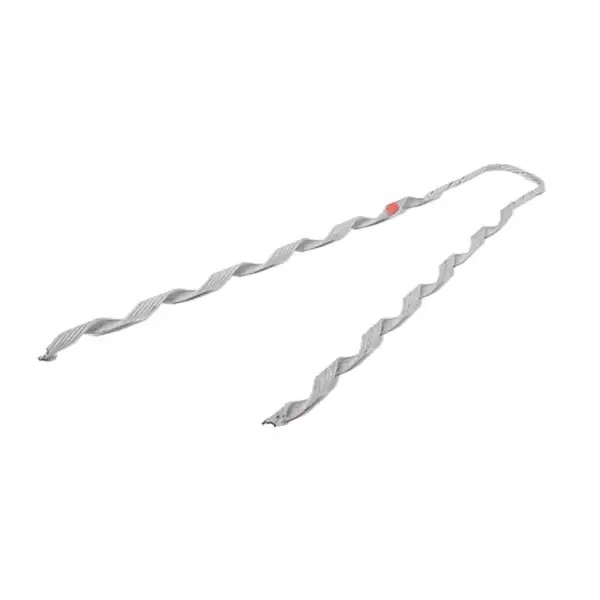

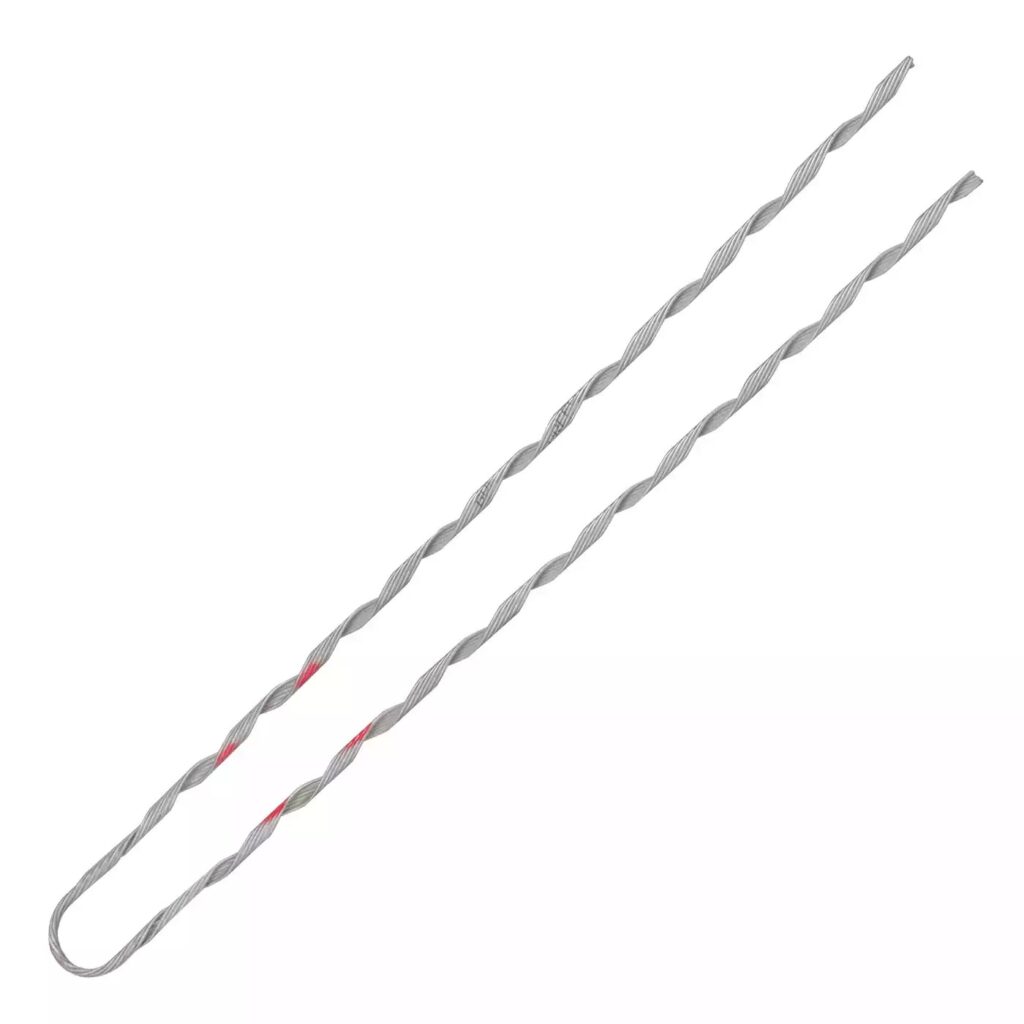

A preformed tension clamp is a component used to fasten conductors to support structures such as poles. Its design helps to withstand the mechanical stresses and environmental conditions. Preformed tension clamps consist of one or more gripping mechanisms that wrap around the conductor. It helps to distribute the tension along the length of the conductor to prevent excessive stress on some points. Preformed tension clamps are from durable materials such as aluminum alloy, steel or galvanized steel. it also has simple installation features since they can install by hand or simple tools. The clamps find use in various applications such as telecommunications, power systems and electrical installations.

Benefits of using preformed tension clamp

Using preformed tension clamps on overhead transmission lines offers various benefits. The clamps contribute to the efficiency, reliability and safety of overhead transmission lines. This is while offering cost-effective solutions for infrastructure maintenance and operation. The following are the benefits of preformed tension clamps for various applications.

- Performance – the clamps have a preformed shape that ensures consistent performance across installations. This helps to maintain the desired tension levels in the conductor. This contributes to the reliability of the transmission line.

- Improved safety – preformed tension clamps help prevent conductor slippage. This can lead to safety hazards.

- Cost-effectiveness – the clamps lead to cost effectiveness due to reduced installation, maintenance and replacement expenses.

- Environmental resistance – the clamps are from materials that offer excellent resistance to environmental factors. These include corrosion, UV radiation and temperature variations. This is to ensure reliable performance in harsh environmental conditions.

- Ease of installation – the clamps have simple installation designs which need minimal tools and labor. It can help to reduce installation time and costs.

- Reduced maintenance – preformed tension clamps are from durable materials that reduce maintenance and increase lifespan.

- Versatility – they are also available in various designs and sizes to accommodate different conductor types and sizes. This makes them suitable for a wide range of overhead transmission line applications.

Materials used for preformed tension clamp

Preformed tension clamps are from materials that offer strength, durability and resistance. Selection of materials for preformed tension clamps depends on various factors. These factors includes such as environmental conditions and performance characteristics. Additionally, it is important to consult with experts for guidance on the best materials for your application needs. The following are the materials used to make the preformed tension clamps.

- Aluminum alloy – the material is lightweight in nature, high strength-to-weight ratio and excellent corrosion resistance. Preformed tension clamps from aluminum alloy are able to withstand mechanical stresses and environmental conditions.

- Stainless steel – this material is corrosion resistance and are durable. This makes it suitable for preformed tension clamps used in outdoor applications. The material is more expensive than other materials due to its performance.

- Bronze – these materials offer good corrosion resistance, mechanical strength and electrical conductivity.

- Galvanized steel – this is a popular choice for preformed tension clamps. The steel has zinc coatings which enhances its corrosion resistance. This makes the preformed tension clamps suitable for outdoor applications.

- Composite materials – these materials offer a lightweight yet robust alternative to traditional clamps. They also provide excellent resistance to corrosion, UV radiation and electrical conductivity.

- Other materials – there are other materials such as brass or copper used in the construction of preformed tension clamps.

Tension clamps used for ADSS cables

Preformed tension clamps work for ADSS (All Dielectric Self-Supporting) cables in transmission lines. ADSS cables have designs to support their own weight without need for extra support. The clamp plays a crucial role in securing ADSS cables to support structures such as poles. Preformed tension clamps help provide secure anchoring and reliable support. This is while ensuring the integrity of the cable. Additionally, it is crucial to get professional guidance on the clamps used for ADSS cables. The following are the ways preformed tension clamps work for ADSS cables.

- Preformed configuration – the clamps manufacture in a preformed shape that conforms to the diameter and profile of the ADSS cable. This design ensures a consistent grip along the length of the cable to maintain the desired tension levels.

- Weather resistance – preformed tension clamp for ADSS is from materials that offer excellent weather resistance. This ensures the clamps can withstand environmental factors. These factors includes moisture, UV radiation and temperature fluctuations.

- Compatibility – the clamps for ADSS cables should be compatible with the specific requirements of ADSS cable installations. This includes cable diameter, tensile strength and installation method.

- Gripping design – clamps for ADSS cables have designs with specialized gripping elements that hold the cable in place. They have shapes to match the contour of the ADSS cable and provides a reliable grip to withstand tension forces.

- Installation – the ADSS cable clamps install at specific intervals along the cable’s route at support structures. They attach to the structure and provides a stable anchoring point for the cable.

- Mechanical strength – the clamps for ADSS cables are from materials that have mechanical strength. This is to prevent slippage of the cable from the support structure to ensure the reliability and stability of the transmission line.

Preformed tension clamp for OPGW cables

Preformed tension clamps for Optical Ground Wire cables have designs to hold the unique characteristics of the cables. OPGW cables are optical fiber cables integrated into the structure of transmission lines. It helps to serve a dual purpose of providing data transmission capabilities and acts as a ground wire for the electrical conductors. The following are the features and considerations for preformed tension clamps used with OPGW cables.

- Cable protection – clamps for OPGW cables have features to protect the cable from abrasion and mechanical stress. This includes rubber or elastomeric inserts within the clamp to cushion the cable.

- Electrical isolation – OPGW cables carry both electrical conductors and optical fibers that need proper electrical isolation. This is to prevent electrical interference between the two systems. They also have insulating materials or design features to maintain the isolation.

- Installation requirements – the clamps for OPGW cables should have designs for ease of installation. This is to ensure proper clamping force.

- Gripping mechanism – the clamps have designs to hold both the optical fibers and the strength members within the OPGW cables. This is to ensure the cable anchors to the support structures while reducing the risk of damage to the optical fibers.

- Corrosion resistance – the cables are from materials within high corrosion resistance. Common materials include aluminum alloy, stainless steel and galvanized steel. They help to ensure longevity of the clamps in harsh environmental conditions.

Tensile strength for preformed tension clamp

The tensile strength of preformed tension clamps varies depending on various factors. These factors include specific design, material composition and intended application. The manufacturers provide specifications and ratings for their preformed tension clamps. This is depending on testing and engineering standards. Tensile strength of a preformed tension clamp is the greatest amount of load that it can withstand before failing. This strength helps to ensure the stability and reliability of overhead transmission lines. The tensile strength measures in units such as kilonewtons or pounds. Common tensile strength ratings for preformed tension clamps range from a few kilonewtons. This is depending on factors such as conductor size, configurations and expected mechanical stresses.

Safety tips when using preformed tension clamps

It is important to focus on safety to prevent accidents and ensure the integrity of the infrastructure. Following best practices and safety tips helps to reduce risk and ensure the safe and effective use of preformed tension clamps. The following are the safety tips to keep in mind when dealing with preformed tension clamps.

- Follow manufacturer guidelines – adhere to the manufacturer’s instructions for the proper installation, handling and maintenance of the clamps. This includes specifications for conductor size, torque requirements and recommended procedures.

- Inspection – inspect preformed tension clamps for any signs of damage, defects or wear. Replace any damaged components to ensure the integrity of the clamp and the safety of the installation.

- Secure work area – maintain a secure work are around overhead lines by implementing safety measures. These include barricades, warning signs and safety cones.

- Use personal protective equipment (PPE) – wear suitable protective equipment including safety gloves, eye protection and headgear. This helps protect against injuries from sharp edges, falling objects or electrical hazards.

- Ensure proper torque – use calibrated torque wrenches to apply the correct torque when tightening bolts.

- Work with qualified personnel – ensure the installation and maintenance tasks involving preformed tension clamps are by qualified personnel.

Frequently asked questions

Preformed tension clamps are components used to fasten conductors to support structures. The clamps help distribute tension along the conductor and maintain its stability.

The tensile strength of preformed tension clamps varies depending on factors such as design, material composition and intended application. Common ratings range from a few kilonewtons to several dozen kilonewtons.

Some benefits of using preformed tension clamps include ease of installation, consistent performance, reduced maintenance, improved safety and enhanced performance.