A rock anchor is a type of anchoring system used in various industries to provide stability and support to the towers or poles that carry the electrical cables. They are also known as rock bolt or rock reinforcement used in areas where the soil or rock conditions are not strong enough to support the weight. They also support the forces exerted by the transmission structure. Rock anchors are mostly used in steep slopes, unstable soil or rocky terrain to add stability and resistance of the structures. Rock anchors have a design that provides load-bearing capacity and distribute the forces acting on the structure. The specific design of the rock anchors depends on factors like terrain, environmental conditions and load requirements.

Components of a rock anchor

A rock anchor consists of several components working together to provide stability and reinforcement. The components also vary depending on the design, application and type of structure. The following are the major types of a rock anchor.

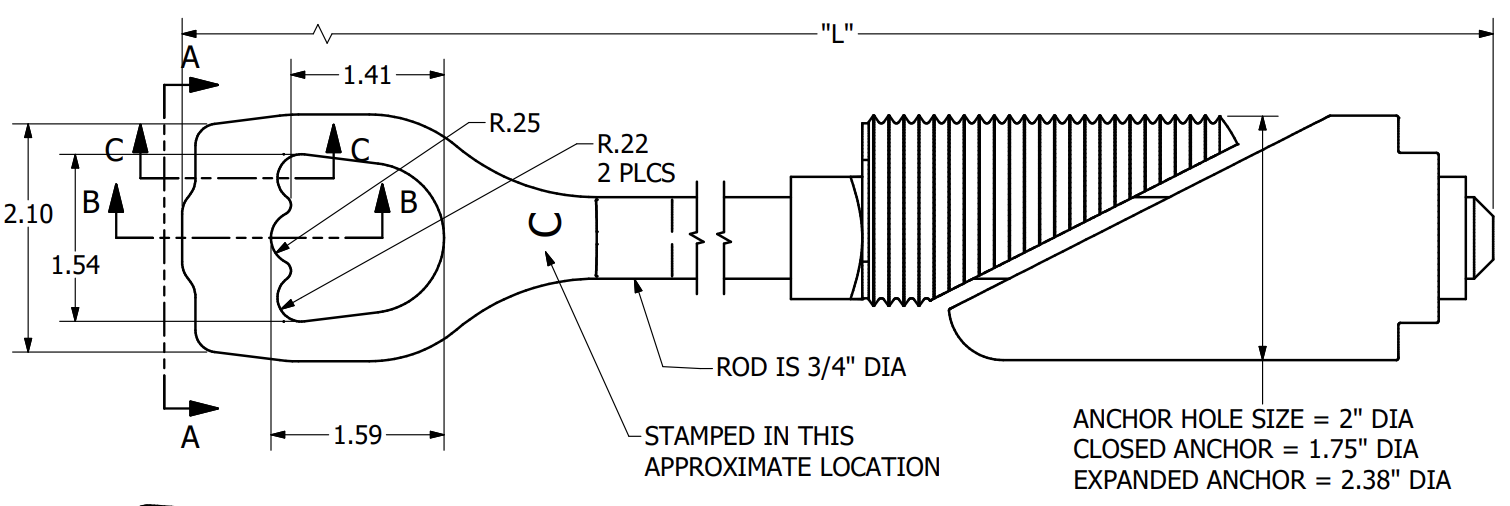

- Anchor head – This is the main part of the rock anchor that connects the anchor rod to the structure to anchor. It provides the interface for transferring the load from the structure to the anchor.

- Anchor rod – This is a steel element that inserts into the drilled hole in the rock or soil. It is the main load-carrying element of the anchor system.

- Grout body – The grout body consists of cement or resin-based grout that injects into the drilled hole surrounding the anchor rod. It provides a bonding and load transfer between the rod and the surrounding rock.

- Anchor plate – The anchor plates used to secure the anchor rod to the anchor head. It thread onto the anchor rod and tightened against the plate.

- Anchor bearing plate – The anchor bearing plate is a load distributing component that positions between the nut and the structure to anchor. This helps spread the applied load from the anchor rod to the structure over a large area.

- Coupler – Multiple anchor rods may need to connect together to achieve the desired length or capacity. It joins two or more anchor rods end-to-end to ensure continuity and load transfer along the entire length of the anchor.

- Drill hole – The drill hole is the cavity created in the rock to accommodate the anchor rod. It drills using special equipment and techniques which ensures proper diameter, depth and alignment for the anchor installation.

Types of rock anchors

Additionally, there are various types of rock anchors used on power transmission lines to add stability and effectiveness. The selection of a particular type of rock anchor depends on various factors such as load requirements, geological conditions, and project specifications. Below are the main types of rock anchors.

- Mechanical expansion anchors – These types of rock anchors consist of a threaded anchor bar with an expanding cone or wedge-shaped end. The anchor inserts into a pre-drilled hole and tensioned creating a frictional resistance against the surrounding rock or soil.

- Self-drilling anchors – Self-drilling anchors have a design with a hollow bar that incorporate drilling and grouting capabilities. They install by drilling into the roc while injecting grout through the anchor rod.

- Grouted anchors – These are also known as bonded anchors which involve injecting cementitious or resin-based grout into the drilled hole surrounding rock or soil to provide load transfer and stability.

- Deadman anchors – Deadman anchors provide lateral resistance against forces acting on retaining walls, slopes or structures. They consist of an anchor rod that extends from the structure ingot a stabilized zone to resist horizontal movement.

- Post-tensioned anchors – Post tensioned anchors use high-strength steel cables with high tension after the grouting process. The tensioning creates comprehensive forces within the anchor system which enhances the load-carrying capacity and stability.

- Soil nailing – Soil nailing is a technique where small diameter steel bars install into the soil to provide reinforcement and stability.

- Rock bolts – Rock bolts used in mining, tunneling and ground support applications. They consist of a threaded bar or rod that install into pre-drilled holes and grouted to provide reinforcement against rock or ground movement.

Applications of rock anchors

The rock anchors are applicable n various industries that require stability, reinforcement and load-bearing capabilities. The following are some common applications of the rock anchors.

- Power transmission and distribution – rock anchors stabilize and support transmission towers, poles and guy wires. The anchors also ensure the structures can withstand the weight of electrical cables and forces exerted by wind and ice.

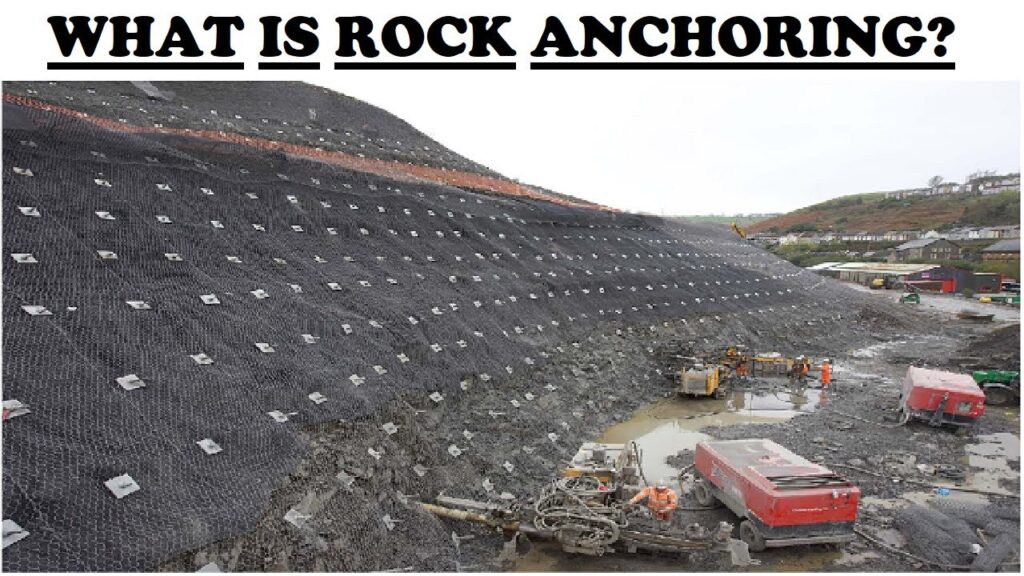

- Slope stabilization – the anchors reinforce and stabilize slopes or embarkments in areas prone to landslides or erosion.

- Moreover, in tunneling and underground excavations, rock anchors enhance the stability of tunnel walls, rock faces, and underground structures. They effectively protect these structures against the pressure exerted by the surrounding ground, thereby reducing the risk of collapses and ensuring worker safety.

- Mining – rock anchors play a vital role in mining operations by providing support in underground mines, shafts and tunnels.

- Bridge construction – the anchors work in construction of bridges to reinforce foundations, abutments and piers. Thus providing additional stability and load-carrying capacity and ensuring the bridge structures withstand dynamic loads.

- Retaining walls – rock anchors work in the construction of retaining walls to prevent soil or rock movements.

- Dam and reservoir construction – the anchors work in the construction of dams and reservoirs to reinforce the structure and improve stability. They also help to withstand hydraulic pressure exerted by the water. This reduces the risk of dam failure and ensures long-term structural integrity.

- Coastal and shoreline protection – the anchors protect the coastal projects to stabilize seawalls, breakwaters and revetments. They help resist the forces generated by waves, tides and currents.

Installation process of rock anchors

The installation process of the rock anchors should be from professionals following industry standards, guidelines and any specific manufacturer recommendations for a particular anchor system. The process may vary depending on factors such as anchor type, site conditions and project specifications. The following is the basic installation process of the rock anchors.

- Prepare the site by removing any vegetation, debris thus ensuring safe access to the anchor locations.

- Drill the shafts into the rock at designated anchor locations based on the engineering calculations along with the niche project requirements.

- Clean the holes to remove any loose debris or cuttings which works through using compressed air. Therefore ensuring other methods ensure a clean and stable hole for the anchor installation.

- Insert the rod into the drilled hole depending on the anchor type which may not only have a threaded end but also an expanding mechanism or a pre-installed anchor head.

- If the support requires grouting, a cementitious or resin-based grout injects into the hole surrounding the anchor rod.

- Attach the head or nut to the exposed end of the anchor rod.

- Subsequently, tension the anchor if necessary by utilizing hydraulic jacks, wrenches, or other equipment. This step is crucial to create the required comprehensive forces within the anchor system, ensuring stability and effective load transfer.

- Perform tests and inspections to ensure the integrity and performance which may involve load testing, pull-out testing or other evaluation methods.

Selecting the best rock anchors

The selection process of the rock anchors should prioritize safety, stability, durability and performance thus ensuring reliability. It is advisable to consult with professionals who provide informed guidelines for the best anchors for your applications. The following are the factors to consider when selecting the best rock anchors.

- Determine the direction and magnitude of any external forces that may act on the structure, such as wind, seismic, or impact loads.

- Evaluate the geological characteristics of the site such as the type of rock, its strength and stability and any potential challenges.

- Consider the site-specific installation constraints like access limitations, available drilling equipment and potential obstructions.

- Assess the need for corrosion protection based on environmental conditions such as exposure to moisture, chemicals or saline environments.

- Also, seek guidance from experienced geotechnical or structural engineers to assess the project requirements, evaluate site-specific conditions for the most suitable anchor type and design parameters.

- Ensure that the selected rock anchors comply with relevant industry standards and regulations. Therefore, they provide guidelines for design, materials, testing and installation procedures to ensure the safety and performance of the anchors.

- Consult with manufacturers specifications, technical data and installation guidelines for the specific anchors.

Frequently asked questions

A rock anchor is also known as a rock bolt which is a type of anchoring system used in various industries to provide stability and support to the towers or poles that carry the electrical cables.

Mechanical expansion anchors, Grouted anchors, Self-drilling anchors, Deadman anchors, Post-tensioned anchors, Rock bolts

They provide enhanced stability

Rock anchors lead increased load capacity

Rock anchors are flexible in design

They are cost effective

Require relatively small holes

Effectiveness depends on geological conditions of the site

Soil masses can be complex and difficult to predict accurately

The rock anchors may require specialized equipment and skilled personnel

Require regular maintenance and inspection