A double arming bolt is a specialized piece of hardware used in construction and installation of crossarms. It is also known as a double-ended arming bolt. It helps to securely connect two crossarms on adjacent utility poles. Double arming bolt also helps to support the electrical conductors and other equipment between them. It acts as connectors that ensure the safe and reliable distribution of electrical power. It is from materials such as steel which provides strength and durability to support the weight of conductors. High quality double arming bolts help to connect crossarms in challenging terrains in South America. Examples of double arming bolts include square head bolt, hex head bolt, dome head, anchor rod bolt, shoulder bolts and hex head machine bolts. They find use in applications such as securing crossarms, maintaining spacing, connecting hardware, enhancing structural integrity, maintenance and repairs.

Key features of double arming bolt

The features of the double arming bolts help when selecting and using these components in overhead lines. They contribute to the safety, reliability and ease of installation. The following are the key features of the double arming bolts.

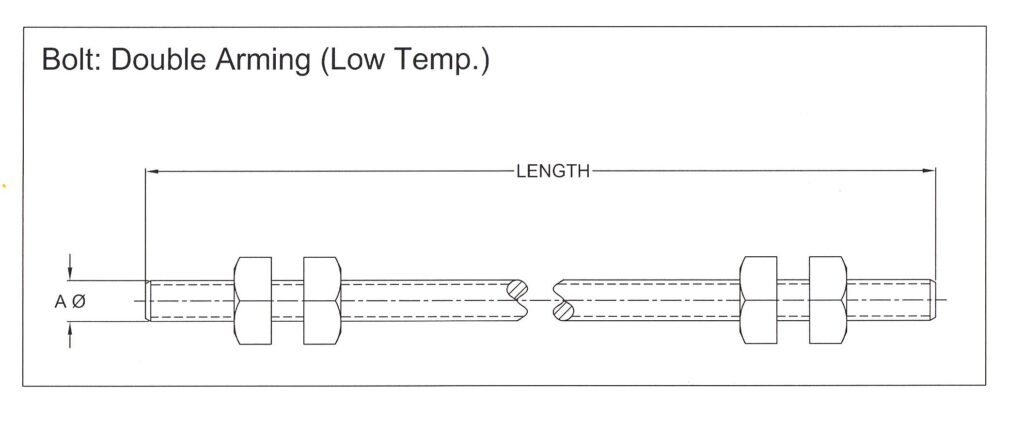

- Threaded ends – this allow them to be securely fastened to crossarms for stable connections.

- Length – the bolts are available in various lengths to accommodate different spacing requirements.

- Corrosion resistance – the bolts have coatings or are from materials that withstand environmental factors.

- Material – double arming bolts are from high-strength steel to ensure durability and load capacity.

- Head type – the head of the bolt may have different shapes like square, hexagonal or dome heads.

- Strength rating – strength rating for double arming bolts helps to ensure they can safely support the weight of conductors.

- Wrench flats – this makes it easier for installers to use wrenches or sockets for tightening and securing the bolt.

- Smooth shoulder – the bolts may have a smooth, unthreaded shoulder portion. This allows for precise spacing between components.

- Galvanization – this helps to provide an extra layer of protection against corrosion in areas with high humidity.

- Locking features – this includes mechanisms such as serrated threads or locking nuts. This helps to prevent the loosening due to vibrations or environmental factors.

Selection and installation of double arming bolt

Selection of double arming bolts includes considering various factors that influence the choice. These factors help to ensure safety, reliability and compliance with local conditions. The factors include environmental condition, utility pole types, load bearing requirements, hardware compatibility, corrosion resistance and strength rating. The installation process is crucial to ensure the stability and reliability. The following is a general installation guide for the double arming bolt.

- Assessment and planning – gather all the necessary tools required for installation. This is including safety gear and other tools. Evaluate the utility poles and crossarms to determine the suitable locations.

- Preparation of double arming bolts – inspect the double arming bolts. This is to ensure they are in good condition and properly threaded. They should be compatible with nuts and hardware used.

- Threaded ends – identify the suitable locations on the crossarms to install the double arming bolts. Use suitable wrench to thread the bolts into the holes.

- Nut installation – place nuts on the threaded ends of the double arming bolts and use the suitable tool to secure tightly. Also, ensure the nuts are flush with surface of the crossarms or other hardware.

- Alignment – ensure the double arming bolts are properly aligned with the intended spacing.

- Torque verification – confirm the double arming bolts and nuts torqued to the manufacturer specifications.

- Locking mechanisms – ensure the locking mechanisms are properly engaged to prevent unintentional loosening.

- Load distribution – verify that the load on the crossarms is evenly distributed between the double arming bolts.

- Inspection – inspect the installed double arming bolts for any defects and ensure they meet the safety standards.

- Documentation – keep detailed records of the installation. This is including dates, location and conditions of the double arming bolts.

Maintenance and inspection of double arming bolts

Proper maintenance and inspection of the bolts helps to ensure the safety and reliability. It also helps to identify and address issues that could lead to potential failures. Additionally, it is important to assess the environmental conditions that may influence the frequency of the maintenance and inspection in South America. The following is a basic guide on the maintenance and inspection in South America.

- Conduct regular visual inspections of double arming bolts to check for signs of wear, damage or corrosion.

- Ensure the double arming bolts are securely attached to the crossarms and utility poles. Tighten any loose bolts to prevent movement or loosening.

- Inspect the double arming bolts for signs of rust or corrosion especially in the coastal or humid areas.

- Ensure the locking mechanisms are functioning properly to prevent unintentional loosening.

- Verify the load on the crossarms is evenly distributed between the double arming bolts to prevent structural issues

- Clean the double arming bolts to remove dirt, debris and any other substances that may compromise the integrity.

- Lubricate the threads and locking mechanisms to ensure they function smoothly and are not prone to sticking.

- Replace any damaged, corroded or unsafe bolts to prevent any accidents.

- Maintain detailed records of the inspections, maintenance activities and any replacements. This helps to keep track of the condition of the bolts over time.

Comparative analysis for double arming bolts in South America

The comparative analysis involves assessing and evaluating various aspects of the bolts. This is evaluating the components used in the construction and maintenance of overhead lines. It also includes analyzing the types, designs, brands and manufacturers of double arming bolts. In addition, it helps to select the double arming bolts that best suits your kind of application. The following are the key factors to include in the comparative analysis.

- Load bearing capacity – assess the load bearing capacity of double arming bolts.

- Corrosion resistance – evaluate the ability of double arming bolts to withstand corrosion. This is especially in coastal and humid areas.

- Locking mechanism – consider the presence of locking mechanisms on the bolt.

- Supplier reliability – evaluate the reliability and reputation of suppliers and manufacturers operating in south America.

- Safety features – study the safety features of double arming bolts. This includes features that boost worker safety and reduce the risk of accidents.

- Customization – assess the availability of customized double arming bolt solutions to meet specific regional infrastructure requirements.

- Environmental adaptability – compare the corrosion resistance and durability of different bolt materials in different regions. Assess the various environmental conditions in South America that may influence the choice of the bolt.

Certification and standards in South America

Standards and certifications help to ensure the safety and reliability of overhead transmission lines. These standards vary depending on country while some may adopt the international standards for double arming bolts. Additionally, there are some general principles and references that are commonly followed in the industry. The following are the standards and certifications for double arming bolts.

- ANSI standards – these are standards that influence the design and safety features of double arming bolts in South America.

- ISO certifications – this relates to the safety, materials and quality, design and manufacturing of double arming bolts.

- ASTM standards – this standard develops and publishes international standards related to material, construction and safety of utility hardware components.

- Local electrical utility regulations – south American countries have their own electrical utility regulations that includes specific requirements. They dictate the materials, specifications and safety features.

Regional market for double arming bolts

There are various factors that influence the regional market for double arming bolts in South America. The market varies depending on size of the electrical utility sector, regulatory requirements and local industry practices. Also, it is important for manufacturers and consumers to understand these factors for success. The following are the common market trends that influence the regional market in South America.

- Infrastructure development – the level of infrastructure development affects the demand for double arming bolts.

- Utility pole types – South America uses various types of utility poles such as wood, concrete or metal. The compatibility of double arming bolts with these pole materials impacts their use.

- Technological advancements – these advances lead to the development of more efficient and durable double arming bolts.

- Utility sector growth – the growth and expansion of electrical utility sector also influences the demand for the bolts.

- Supplier network – the availability of reliable suppliers and manufacturers also impact the supply of double arming bolts.

Frequently asked questions

Double arming bolts are a type of hardware used to secure crossarms and hardware components on utility poles. They help to maintain the stability and reliability of overhead electrical distribution systems in South America.

The widely used double arming bolt diameter is 5/8, 3/4 and 1/2 inch with different length.

South America uses a variety of utility pole materials like wood, concrete and metal. The choice of double arming bolts depends on the compatibility with these pole materials.