A shackle insulator is a type of insulator used to support and insulate wires or conductors in electrical installations. It helps to connect the insulator to the support structures such as pole or crossarm. Shackle insulators provide electrical insulation to prevent current leakage and short circuits. They also support the weight of the conductors and withstanding mechanical stress. Its designs vary depending on voltage levels, environmental conditions and specific application requirements. Shackle insulators come in various sizes and shapes to hold installation configurations and load requirements. They also help to secure the ADSS cable in place while maintaining electrical isolation. Shackle insulators also help to secure OPGW cable to supporting structures. This helps to ensure mechanical stability. It is important to consider the design of the insulator which must follow relevant industry standards.

Construction of the shackle insulator

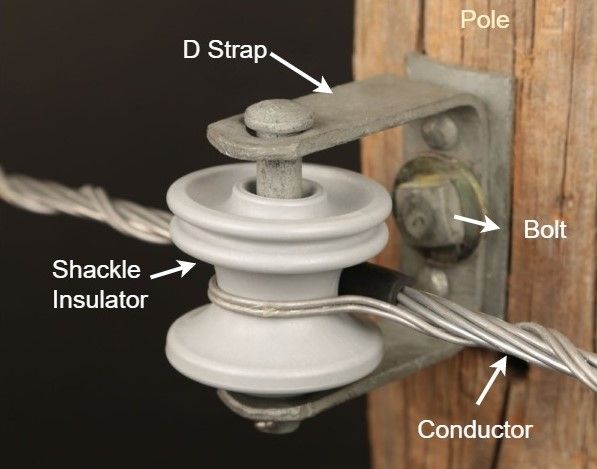

The construction of the shackle insulator varies depending on several factors. These include voltage rating and mechanical load capacity. The basic design consists of the insulating part and shackle. It is from materials like steel, aluminum or composite materials. These materials are able to withstand mechanical stresses and environmental factors. This is including UV radiation, pollution and temperature variations. Their design helps to ensure reliable performance and durability in electrical distribution. The following is a more detailed description of the two main components of the shackle insulator.

- The insulating part – this is the part made from porcelain or polymer materials. They provide high mechanical strength and electrical resistance. They are lighter in weight, resistant to vandalism and better resistance to environmental factors.

- Shackle – this is the metal or composite component that attaches the insulator to the support structure. It is able to hold the insulator in place while providing a means for connecting the conductor.

Mounting hardware for shackle insulator

Shackle insulators need mounting hardware to provide secure attachment to the support structures. They also enhance its ability to ensure proper electrical insulation and mechanical strength. Additionally, it is advisable to use appropriate hardware and follow manufacturer’s guidelines. This is to ensure the safe and reliable operation of electrical distribution and transmission systems. The mounting hardware for shackle insulators includes the following components.

- Eye or clevis – this is the part that connects to the support structure. It can be in the form of an eye or clevis depending on the specific mounting arrangement.

- Shackle pin – this helps to secure the shackle to the insulator. It inserts through holes in the shackle and the insulator and then secured with a nut.

- Locking nut – a locking nut or cotter pin serves to secure the shackle pin in place. This prevents it from loosening due to vibrations.

- Washers – these work between the components to provide extra support and prevent damage to the insulator.

- Support structure – extra hardware such as bolts, nuts and washers attach the shackle insulator to the supporting structure.

- Corona rings – the rings install around the shackle insulator to reduce the risk of corona discharge and electrical losses.

Technical specifications for shackle insulators

Manufacturers should provide technical specifications to ensure the right fit for your application needs. It also helps to ensure the safe and reliable operation of the infrastructure. Technical specifications for shackle insulators depend on factors such as voltage rating, mechanical load capacity and material. Additionally, it is advisable to consult with manufacturers and adhere to applicable standards and regulations. The following are the common technical specifications for shackle insulators.

Main Dimensions

| H | 88mm |

| D | 100mm |

| d | NONE |

| d1 | 57mm |

| d2 | 18mm |

| R | 13mm |

| Mechanical Fialing load | 17.8kN |

- Voltage rating – shackle insulators are available in various voltage ratings. This is to suit different applications. They range from low voltage to high voltage transmission lines.

- Material construction – shackle insulators are from porcelain which offer high mechanical strength. They are lighter in weight and offer better resistance to vandalism and environmental factors.

- Corona performance – the shackle insulator has designs to reduce corona discharge which can lead to energy losses. Use of corona rings help to enhance corona performance.

- Mechanical load capacity – the insulators are able to withstand mechanical loads such as wind and ice. This is typically specified the greatest allowable load in pounds or kilograms.

- Compliance with standards – shackle insulators should follow relevant industry standards and specifications. These include standards set by IEC, ANSI and other national standards bodies.

- Creepage distance – this is the shortest distance along the insulating surface between two conductive parts. It helps to prevent electrical leakage and flashover. It should meet the applicable standards and regulations.

- Environmental resistance – the insulators should withstand environmental factors. This is including pollution and UV radiation. Polymer insulators offer excellent resistance to environmental degradation.

Industry advancements and updates for shackle insulators

There have been several advancements and updates in the shackle insulator industry. They aim at improving performance, durability and efficiency. They reflect the ongoing commitment to innovation and continuous improvement. Additionally, it is advisable to consult with industry professionals for the best technology. The following are the common advancements in shackle insulator industry.

- Composite materials – the use of composite materials offer advantages. This is including lightweight, better resistance and reduced maintenance.

- Corona performance – there is innovation to improve corona performance of shackle insulators. This includes use of corona rings, improved surface finishes and enhanced insulation materials.

- Smart insulators – advancements include sensor technology and communications systems. They have enabled the development of smart insulators. These smart insulators can provide real-time data on the condition of the electrical infrastructure.

- Standards and testing – there are ongoing development of industry standards and testing protocols. They help to ensure the reliability and performance. This includes standards for mechanical testing, electrical testing and environmental testing.

- Environmental resistance – there is development of shackle insulators with improved resistance. They help to withstand excellent resistance to pollution, UV radiation and temperature fluctuations.

- Improved design – manufacturers focus on refining the design of shackle insulators. This is to enhance their mechanical strength. They also help to optimize the shape and configuration of insulators for specific application.

- Manufacturing processes – manufacturers explore innovative manufacturing processes like injection molding. This helps to increase production efficiency, reduce costs and improve product quality.

Standards and certifications for shackle insulators

Insulators must adhere to various standards and certifications to ensure they meet industry criteria. This is to ensure for quality, safety and performance. Standards provide assurance for quality, safety and performance. Additionally, it is advisable to consult with manufacturers to get certifications from recognized testing laboratories. The following are the common standards and certifications for shackle insulators.

- IEC for overhead lines – this is an international standard that specifies requirements for composite suspension and tension insulators.

- ANSI electrical power insulators – this provides definitions, test methods and acceptance criteria for electrical power insulators.

- ISO certifications – this ensures that a manufacturer has implemented a quality management system that meets internationals standards. This demonstrates their commitment to quality and continuous improvement.

- UL standards – this covers the safety requirements for composite station post insulators. This may include shackle insulators used in electrical distribution and transmission systems.

- CSA standards – this is a Canadian standard that outlines the verification requirements for composite insulators. This includes shackle insulator in overhead line applications in Canada.

- CE Marking – shackle insulators must follow relevant European standard to bear the CE mark. This indicates conformity with essential health, safety and environmental protection requirements.

- Country-specific standards – shackle insulators need to follow country-specific standards and regulations.

- IEEE standards – this standard provides guidance on cleaning insulators including shackle insulator. This is to maintain their electrical performance and prevent pollution.

- DIN standards – this is the European standard that specifies requirements for composite suspension and tension insulators.

- BS standards – this is a British standard that specifies requirements for composite suspension and tension insulators used in AC line systems.

Frequently asked questions

Shackle insulators categorize based on their material construction including porcelain and polymer insulators.

Recent advancements include the use of composite materials, improved design for enhanced mechanical strength ad corona performance. They also include development of smart insulators with monitoring capabilities and advancements.

Maintenance activities may include periodic inspections for damage or contamination, cleaning to remove pollutants and replacement of insulators.

Shackle insulators provide electrical insulation to prevent current leakage and short circuits. They also support the weight of conductors, withstand mechanical stress and ensure safe operation of overhead line systems.