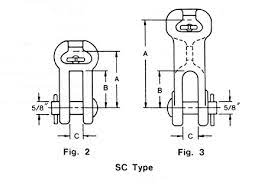

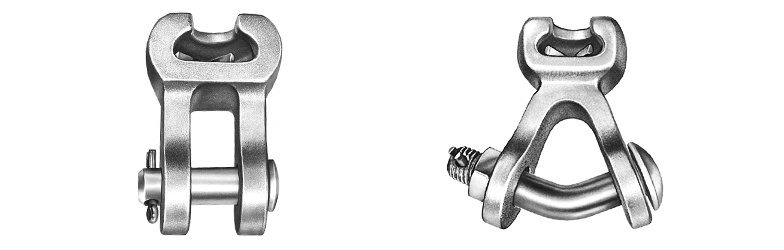

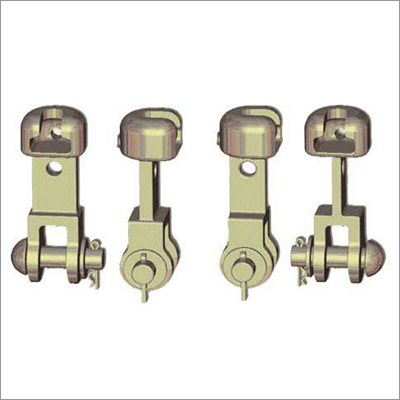

A socket clevis is a type of hardware used to securely attach insulators and other equipment to utility poles. It consists of a socket and a clevis that help with the attachment. The socket is a cylindrical component with a hole at one end helps designed to accommodate the ball of an insulator pin. It allows for the attachment of the insulator pin which inserts into the socket. The clevis is a component with holes at both ends. It helps to ease the attachment of the insulator with clevis pins, cotter pins and other fasteners. It is from materials such as steel, aluminum or composite materials. Utility companies trust socket clevis solutions to withstand diverse climates in South America. Common types of socket clevis include angle socket clevis, yokes, double socket clevis and tension socket clevis. They find use in applications such as insulator attachment, conductor support and crossarm attachment.

Key features of socket clevis

Socket clevises has various features that make them reliable and effective. These features help to secure attachment and proper alignment of insulators and conductors. The following are the key features of the socket clevis.

- Clevis attachment – the clevis is a U-shaped component with holes at both ends. It serves as an attachment point for insulator, conductors and other equipment.

- Material – socket clevis is from materials that withstand environmental conditions and electrical conductivity. These materials include steel, aluminum or composite materials

- Load capacity – they are available in various load-bearing capacities. This helps to support different mechanical loads.

- Corrosion resistance – they have corrosion resistance making them suitable for use in diverse environmental conditions.

- Hot-dip galvanizing – hot dip galvanizing to enhance their corrosion resistance. This makes them suitable for regions with high humidity or salt water.

- Durability – high-quality clevises are able to withstand mechanical loads, temperature fluctuations and environmental factors.

- Ease of installation – socket clevises are easy to install to facilitate efficient attachment of insulators, conductors and other utility poles.

- Versatility – the clevises are available in various types and designs. They are able to accommodate various applications.

- Socket design – the cylindrical part of the socket accommodates the insulator pin or hardware. This allows for secure connection while providing electrical isolation.

- Adjustability – the socket design offer the ability to reposition the attached insulators.

Selection and installation of socket clevis

The selection process is crucial to ensure safe and reliable operation. It includes considering several factors to match the clevis to the specific requirements of your project. The factors include voltage levels, environmental conditions, material selection, clevis type and load capacity. The installation process should ensure the secure attachment of insulators, conductors and other equipment to utility poles or crossarm. Additionally, it is advisable to consult with industry experts for installation whenever in doubt. The following is a basic installation process of socket clevis in South America.

- Preparation – collect all the necessary tools and equipment needed for the installation. This includes wrenches, socket wrenches, insulator pins and clevis pins among others. Gather all the safety gear needed for the installation.

- Pre-installation inspection – inspect the socket clevis to ensure it is in a good condition. It should be free from any defects, damage and contaminants.

- Positioning – determine the correct positioning for the socket clevis on the utility pole or crossarm. Ensure it aligns with the insulator pin to conductor attachment point.

- Attachment hole alignment – position the socket clevis so that the attachment hole aligns with the insulator pin.

- Attachment of the clevis pin – insert the clevis pin through the hole in the in the clevis and the insulator pin or conductor. The clevis pin secures the socket clevis in place.

- Torque application – use a torque wrench to apply the recommended torque to the socket clevis threads to ensure a secure fit.

- Testing – inspect the installed socket clevis to ensure it is securely attached and that there are no visible defects.

- Documentation – maintain detailed records of the socket installation. This is including date, location and any specific torque values.

Maintenance and inspection of socket clevises

Proper maintenance and inspection help to ensure the reliability and safety of electrical systems. It also helps to address the potential issues and prevent potential failures of the systems. Additionally, it is important to consult with local regulations and industry standards to maintain the integrity. The following is a basic guide for maintenance and inspection of socket clevis.

- Conduct routine visual inspections of socket clevis to identify any visible signs of wear, damage or corrosion. Check for cracks, rust, bent clevis pins and any abnormalities.

- Consider the specific environmental conditions in South America. These include high humidity or temperatures in mountain regions.

- Apply suitable lubricant to the clevis threads and attachment points. This helps to prevent corrosion and makes it easier to adjust or replace components.

- Ensure the clevis pins are properly tightened and secured with cotter pins. They help to torque to a specific value during installation and check they remain within the recommended torque range.

- Inspect and adjust the angle as necessary to maintain proper alignment of insulators and conductors.

- Check for signs of corrosion and remove rust and apply anti-corrosion coatings as needed to extend the lifespan of the clevis.

- Replace worn, damaged or corroded components to maintain system integrity.

- Maintain detailed records of each inspection. This is including date, location and the conditions of the socket clevises.

Comparative analysis of socket clevis in South America

A comparative analysis of socket clevis involves assessing different factors. These materials, designs, manufacturers and compliance with standards. It helps to make an informed decision that meets the needs of your application. it also helps the safety and reliability of your electrical systems. The following are the factors to include in a comparative analysis in South America.

- Load bearing capacity – consider the load bearing capacity of socket clevises. Select the ones that can withstand greater mechanical loads.

- Variety of types – compare the availability of different socket clevis types. These includes standard, angle, yoke, adjustable and others.

- Supplier reputation – consider the reputation of socket clevis suppliers or manufacturers. They should have track record in providing high-quality and reliable products.

- Cost-effectiveness – compare the prices and socket clevises from different suppliers. Consider factors like material quality, load capacity and compliance with standards.

- Maintenance and durability – assess the durability and expected lifespan of socket clevises from different manufacturers. Consider the ease of maintenance and availability of replacement components.

- Material – compare the materials used in socket clevis construction. Select for materials that offer high corrosion resistance for regions with high humidity or salt exposure.

- Environmental suitability – assess the socket clevis design and materials for the specific environmental conditions of the installation.

Certifications and standards of socket clevis in South America

There are various standards and certifications that ensure the safety and reliability. They vary depending on the country and project requirements. Additionally, it is advisable to consult with local authorities and government agencies to understand the environment. The following are the certifications and standards in South America.

- IEC standards – these are standards for electrical and electrical technologies for dimensions and requirements for socket clevises.

- ANSI standards – ANSI standards regulate the use of socket clevis in south America which covers clevis and tongue fittings.

- ASTM standards – these are standards referenced for materials and testing for socket clevises.

- Local regulatory standards – socket clevises comply with the national or regional standards and regulations for electrical equipment.

- ISO certifications – these standards offer the quality and performance of socket clevises.

- NEMA standards – these standards are recognized in South America foe socket clevises and electrical equipment.

Regional market for socket clevises in South America

There are various factors that influence the regional market for socket clevis in South America. These factors include the growth of energy and infrastructure sectors, regulatory requirements and the diversity of environmental condition. Also, it is recommended for manufacturers and suppliers to understand the market trends for their success. The following are the factors that shape the regional market for socket clevis.

- Growth of the energy sector – the significant growth in the energy sector includes the expansion of electrical systems. Thie growth drives the demand for socket clevises in the country.

- High-voltage transmission lines – the demand for socket clevises depends on the voltage level of the infrastructure.

- Local manufacturing – the presence of local manufacturers influences the availability and supply of socket clevises.

- Export opportunities – manufacturers may explore export opportunities to neighbouring countries contribute to the growth of the regional market.

- Maintenance and replacement market – the maintenance and replacement market for socket clevises should grow in the coming years. This helps to improve the reliability of electrical systems.

Frequently asked question

A socket clevis is a hardware component used to secure insulators, conductors and other equipment in overhead electrical systems. It mainly works in south American countries to support electrical transmission and distribution lines.

Local manufacturers often offer advantages such as shorter lead times, a better understanding of regional conditions and the ability to provide products tailored to the local market.