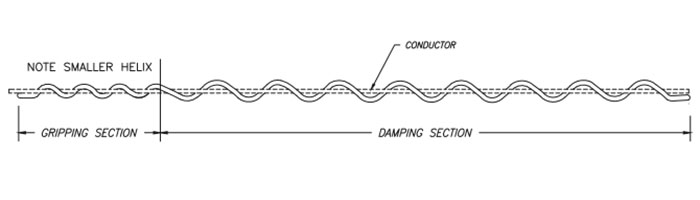

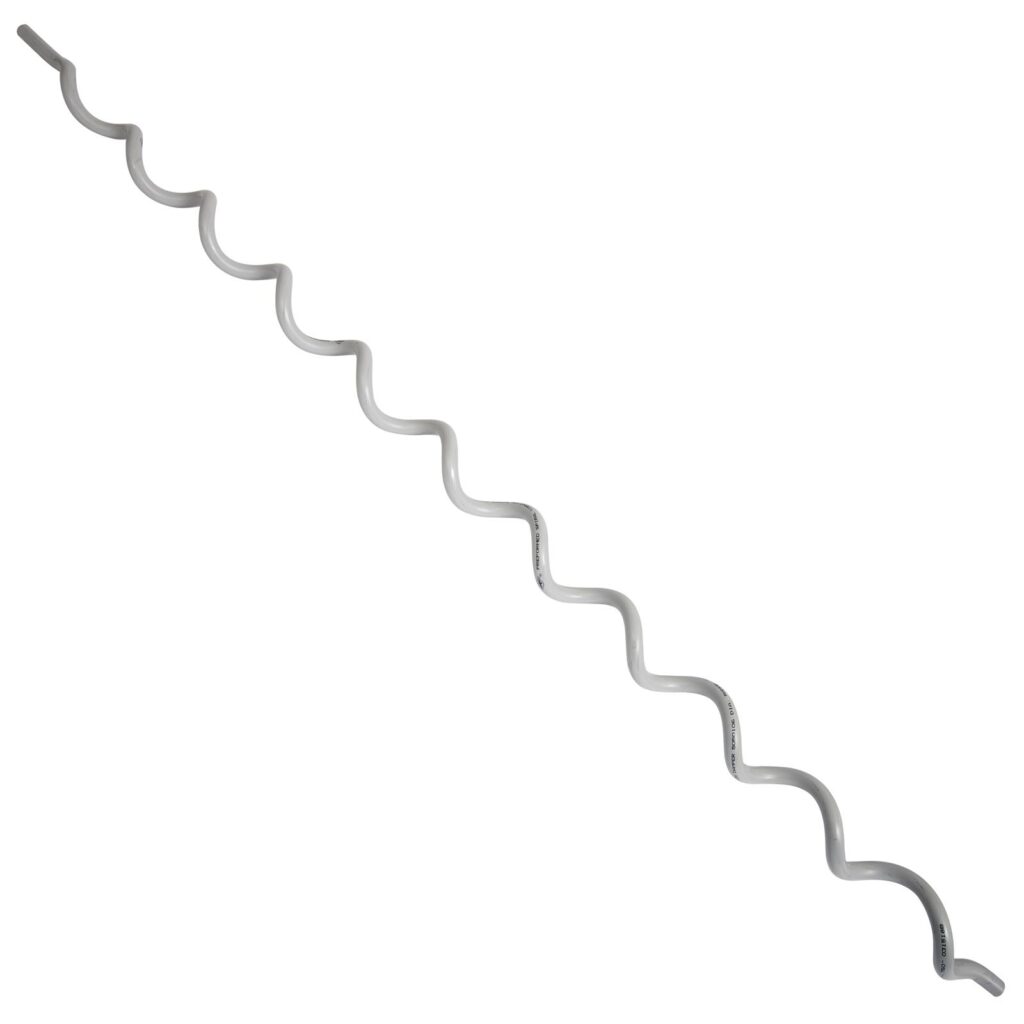

Spiral vibration damper refers to a component used to mitigate the effects of aeolian vibrations on conductors. The vibrations occur when wind flows over the transmission lines which causes the vibrations. The occurrence of vibrations on conductors may lead to fatigue failure over time. It consists of a helical shape installed along the length of the conductor. Its main purpose if to disrupt the regular pattern of vibrations by introducing controlled damping. Spiral vibration dampers are from lightweight and durable materials. It installs at regular intervals along the length of the conductor. Their use increases the conductor lifespan, improved system reliability and reduced maintenance costs. Spiral vibration dampers enhance the reliability of power transmission lines in South America. Common types include helical rod dampers, helical spacer dampers and helical conical dampers. They find use in applications like transmission lines, mountainous and coastal areas.

Key features of spiral vibration damper

The spiral vibration damper has features that promote their sustainability and adaptability. They also help them to provide safe and secure connections. The following are the common features of the damper.

- Spiral design – this spiral shape allows the damper to induce controlled damping and mitigate aeolian vibrations.

- Material – their lightweight and durable materials ensure resistance to environmental factors. These materials include aluminum, composite alloys or fiberglass.

- Frequency control – their design also provides change to match the specific characteristics of the conductor.

- Galvanized finish – galvanization protects the damper from environmental elements and extends their lifespan.

- Tuned mass damping (TMD) – these are systems designed to absorb specific frequencies of vibrations. This is to enhance the dampers effectiveness in controlling targeted vibration ranges.

- Weather resistance – this feature ensures the damper continues to perform in diverse climates.

- Aerodynamic damping – this disrupts the regular pattern of vibrations caused by wind flow.

- Installation – proper installation helps to achieve the desired damping effect. It also ensures uniform protection along the transmission line.

- Variable sizes – availability of different sizes help to accommodate different conductor types.

Selection and installation of spiral vibration damper

Proper selection of the spiral vibration damper helps to ensure the optimal performance of the application. It also includes considering various factors that influence decision making. The factors include conductor type and diameter, wind conditions, material, costs and installation ease. The installation should involve careful planning and execution. This is to ensure optimal performance in mitigating vibrations. The following are the general steps for installing spiral vibration dampers.

- Site assessment – conduct a thorough site assessment to understand the specific characteristics of the project. This includes conductor type, diameter, wind patterns and environmental conditions.

- Damper selection – choose the spiral vibration dampers that are suitable for the conductor type, wind conditions and frequency range of vibrations in the area. Consider factors such as material, coating and compliance.

- Installation spacing determination – calculate the spacing for installing the dampers along the line.

- Installation preparation – gather all the necessary tools and equipment for the installation process. This involves mounting hardware, safety equipment and specialized tools required.

- Safety measures – use suitable protective equipment and follow any safety regulations relevant.

- Installation points – find the designated installation points along the transmission line. This is mainly where the dampers will mount.

- Attach the dampers to conductors – attach the dampers to the conductors at desired installation points.

- Inspect installation – conduct a thorough inspection of the installed dampers. This is to ensure they are securely attached and properly spaced.

- Testing – perform tests to assess the effectiveness of the dampers in controlling vibrations. This involves observing lines behaviour during different wind conditions

- Documentation – maintain detailed records of the installation. This is including location of each damper, adjustments made and observations.

Maintenance and inspection of spiral vibration dampers

Regular maintenance and inspection of spiral vibration dampers ensures their continued effectiveness in mitigating aeolian vibrations. The frequency of the activity depends on the environmental conditions of the installation region. Additionally, it is advisable to consult with industry professionals once in a while. The following is a basic guide for maintenance and inspection of the spiral vibration dampers.

- Conduct regular visual inspections of the spiral vibration dampers. This is to check for any visible signs of damage, wear or corrosion. Check to ensure the dampers are securely attached to the conductors.

- Examine the structural integrity of the dampers including the spiral shape and any adjustable features.

- Ensure fasteners, bolts, or clamps are in good condition and properly tightened.

- Assess the condition of the coating looking for any areas where the coating may lead to corrosion.

- Verify the dampers maintain the specified spacing and address any misalignment promptly.

- Confirm the adjustable features are set according to the environmental conditions. Adjust if necessary to optimize the dampers performance.

- Consider environmental conditions at the installation site to prevent corrosion from various elements.

- Perform emergency inspections after severe weather events like storms or high winds. This is to check for potential damage.

- Keep detailed records of each inspection including maintenance activities performed and observations made.

Comparative analysis of spiral vibration dampers in South America

Conducting a comparative analysis involves evaluating various factors such as performance and material durability. It also helps to make decisions on the best spiral vibration dampers that meet the project specifications. Additionally, it is advisable to collaborate with local experts and engineers to make informed decisions. The following are the factors to include in a comparative analysis in South America.

- Performance in various conditions – evaluate how the spiral vibration dampers perform under different wind speed and patterns.

- Adaptability to specific terrains – consider how the dampers adapt to different terrains. This is including mountainous areas, plains and coastal regions.

- Compliance with local standards – ensure the selected dampers comply with local standards and regulations. This is to ensure their safety and suitability for use.

- Ease of installation – evaluate the installation process and requirements for each damper. They should be easy to install and maintain to reduce the operational cost.

- Environmental impact – evaluate the environmental impact of the materials used. Consider dampers made from environmentally friendly materials.

- Cost effectiveness – compare the upfront costs and long-term benefits of different damper models. Consider factors such as durability, maintenance requirements and overall reliability.

- Performance – assess the long-term performance of dampers and consider any available data demonstrating their performance.

- Customization and adjustability – evaluate whether the dampers offer customization options such as adjustable pitch.

- Material durability – assess the durability of damper materials to withstand various environmental conditions.

Certifications and standards in South America

The standards and certifications in South America vary by country and they help to ensure the safety, reliability and compatibility of the dampers. Most of the south American countries take after the international standards and regulations for spiral vibration dampers. Also, it is advisable to consult with local regulatory bodies to understand the environment in the region. The following are the standards and certifications in South America.

- IEC standards – these are standards for electrical equipment including spiral vibration dampers. They provide guidelines for design, testing and performance of various components used in electrical systems.

- ISO certifications – this is an internationally recognized quality management standard. It helps to ensure adherence to quality and performance of the product.

- ANSI standards – this is an American standard for certain electrical components including spiral vibration dampers.

- National electric code – this is an American standard that influence some south American countries to ensure safety practices.

- Country-specific standards – each south American country has their own set of standards and certifications for electrical equipment. They include INMETRO in Brazil and IRAM in Argentina.

Regional market for spiral vibration damper in South America

There are various factors that influence the local demand and supply of spiral vibration dampers. They include market trends, manufacturers, brands, development and competition. These factors may help to make decisions for the right spiral vibration damper. The following are the factors that shape the regional market for spiral vibration damper in South America.

- Infrastructure development – development in expansion and upgrades require the use of spiral vibration dampers.

- Government regulations – these are initiatives elated to grid reliability, energy efficiency and environmental sustainability. Friendly policies may influence the demand for vibration dampers.

- Technological advancements – innovations such as material, aerodynamics and customization options attract interest from utilities operators.

- Environmental conditions – South America has varying wind patterns and terrain which influences the choice of vibration dampers.

- Competition – availability of manufacturers and suppliers in the region contribute to market dynamics. This may also include pricing, product features and customer support.

Frequently asked questions

A spiral vibration damper plays a crucial role in overhead transmission lines. It helps in vibration control, prevention of galloping, conductor protection, enhanced line stability and reduced conductor fatigue.

Spiral vibration dampers contribute to the reliability of power grids through various mechanisms that enhance the performance and longevity of transmission lines. This is mainly through vibration control, conductor protection and reduction of line failures.