A spiral vibration damper is a device used to control aeolian vibrations in ADSS cables. ADSS cables are fiber optic cables designed for aerial installations. Aeolian vibrations can lead to fatigue and potential damage over time. These vibrations are from wind-induced oscillations and other environmental conditions. The dampers install along the length of the cable to dampen the vibrations and reduce stress on the cable. Spral vibration damper consist of a helical-shaped metallic rod attached to the cable at regular intervals. The spiral shape helps to disrupt the flow of wind around the cable and reduces the amplitude of vibrations. Control of these vibrations help to increase the lifespan of ADSs cables and ensure reliable performance. Spiral vibration dampers find use in power transmission and telecommunication applications.

Properties of spiral vibration damper

Spiral vibration dampers for ADSS cables have several properties that make them effective in controlling aeolian vibrations. These properties work together to mitigate the aeolian vibrations in ADSS cables. They also help to ensure the reliable performance in outdoor environments. The following are the various properties of spiral vibration dampers.

- Material composition – the dampers are from high strength material like aluminum alloy or steel. This helps to ensure durability and longevity in outdoor environments.

- Attachment mechanism – the dampers have designs to attach to the ADSS cable at regular intervals. They may have features like clamps or other mechanisms for secure and reliable installation.

- Resonance frequency – they have resonance frequency that matches the natural frequency of the cable system. This is to ensure optimal damping performance by dissipating energy from cable vibrations.

- Maintenance – the dampers need periodic inspection to ensure they attach and function as intended. This inspection is during routine cable maintenance checks.

- Spiral shape – the spiral shape is to disrupt the flow of wind around the cable. This helps to induce turbulence and reduce the amplitude of cable vibrations.

- Weight – the weight of the damper helps to provide effective damping without adding excessive load to the cable. The balance ensures the cable remains supported while reducing vibration amplitudes.

- Weather resistance – the dampers are able to withstand various weather conditions. This is including high winds, rain, snow and UV exposure. This is to ensure long term performance and reliability in outdoor installations.

Limitations of materials used in the construction of spiral vibration damper

Spiral vibration dampers control aeolian vibrations in ADSS cables without damage. Materials play a crucial role in the performance and durability of spiral vibration dampers. Limitations of the materials used limit their effectiveness, durability and performance. Proper selection considers factors such as environmental conditions, mechanical requirements, cost and sustainability. The following are the limitations of materials used.

- Corrosion resistance – some materials such as steel or aluminum may be susceptible to corrosion when exposed to moisture or salt. This can weaken the dampers and lead to reduced effectiveness. Corrosion may also compromise the structural integrity.

- Mechanical strength – the mechanical strength of the dampers is crucial to withstand stresses imposed by wind loads. Lack of mechanical strength compromises the damping effect and causes damage to cables.

- Environmental impact – consider factors such as resource depletion, energy consumption during manufacturing and recyclability. These factors influence the environmental sustainability of the materials.

- Installation and maintenance – some of the materials need use of special installation techniques. This includes materials that are difficult to weld may need extra labor or equipment for installation.

- UV degradation – exposure to UV radiation causes materials such as plastics or polymers to degrade overtime. This leads to loss of mechanical strength, discoloration and failure.

- Temperature sensitivity – some materials show changes in mechanical properties with fluctuations in temperature. Some plastics may become brittle at low temperatures which affects their damping performance.

- Costs – the cost of materials used in dampers can be a limiting factor. Materials with properties such as high strength or corrosion resistance may be more expensive.

Spiral vibration dampers for ADSS cables

Spiral vibration dampers for ADSS cables help to mitigate aeolian vibrations caused by wind. The dampers have designs to disrupt the flow of wind around the cable and reduce the amplitude of vibrations. Additionally, it is important to ensure proper selection, material, design and maintenance for effectiveness. The following are the key points about spial vibration dampers for ADSs cables.

- Design – the dampers consist of a helical shape metallic rod attached to the ADSs cable at regular intervals. This shape helps to induce turbulence in wind flow which dissipate the energy of the vibrations.

- Installation – the dampers install on the ADSS cable during installation or as maintenance activities. They attach to the cable using clamps or other mechanisms to ensure proper alignment and effectiveness.

- Effectiveness – SVDs help in controlling aeolian vibrations within a certain frequency range. They also have designs to match the resonance frequency of the cable system to provide optimal damping performance.

- Environmental considerations – spiral vibration dampers are set to withstand environmental conditions. this is including high winds, rain, snow and UV exposure. They help to provide reliable performance in outdoor installations.

- Material – the dampers are from materials with high strength and corrosion-resistant materials. They help to ensure durability and longevity in outdoor environments.

- Spacing – the spacing between spiral vibration dampers along the length of the ADSS cable depends on various factors. These include cable diameter, wind conditions and required damping performance.

- Maintenance – spiral vibration dampers may need periodic inspection to ensure proper attachment and functionality.

Accessories used with Stockbridge dampers in ADSS cables

There are several accessories used in conjunction with spiral vibration dampers to optimize their performance. They also ensure the stability and longevity of ADSs cables. Additionally, it is advisable to seek professional help for guidance on the accessories to use for your application. Some of the accessories are as discussed below.

- Dead-ends – these help to anchor ADSS cables to support structures such as poles or towers. They also ensure proper tensioning of the cables to prevent excessive movement.

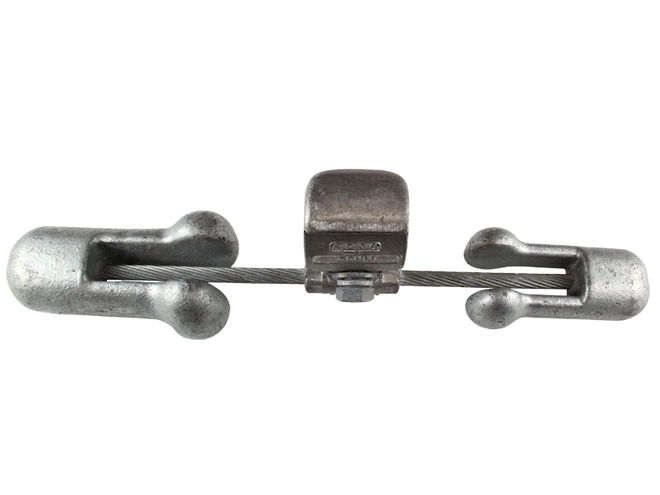

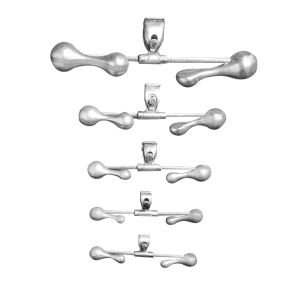

- Cable Stockbridge dampers – these dampers install at specific intervals along the ADSS cable. This is to provide extra damping of aeolian vibrations. These dampers consist of a weight suspended on a cable loop to absorb and dissipate vibration energy.

- Anti-galloping devices – these work in areas prone to galloping which is high-amplitude and low-frequency motion. They help to stabilize the cables and reduce the risk of damage.

- Mounting hardware – these include bolts, nuts, washers and brackets to secure the dampers. They help support structures to the ADSS cables. Proper sizes of the hardware help to ensure the stability and effectiveness of the accessories.

- Preformed line products – these are fittings designed to ease the installation of spiral vibration dampers on ADSS cables. They provide a secure attachment point for the dampers and ensure proper alignment along the length of the cable.

- Vibration monitoring systems – the monitoring systems install along the length of the ADSS cable. They help to detect and analyze the vibrations in real-time. The systems provide valuable data for optimizing the placement and effectiveness of the dampers.

- Weatherproofing materials – these include tapes, wraps or coatings that protect the dampers from environmental factors. This helps to prolong the lifespan of the accessories and ensure reliable performance.

Industry advancements and updates for spiral vibration dampers

There are several industry advancements related to spiral vibration dampers used in ADSS cables. They reflect the ongoing efforts within the industry to improve the performance, reliability and sustainability of dampers. Also, it is advisable to check with experts in the industry for guidance on the advancements. The following are the trends and advancements for spiral vibration damper.

- Material innovation – the advancement in material science leads to the development of new materials with improved properties. This has led to exploration of materials with enhanced corrosion resistance, higher strength-to-weigh ratio and resistance to UV radiation.

- Integration with monitoring systems – the advancements involve integrating the dampers with monitoring systems. the systems can detect and analyze cable vibrations in real-time. This allows for active maintenance and adjustments to damping systems.

- Improved installation methods – these advancements focus on simplifying the installation process. This includes the development of special tools and equipment for efficient installation.

- Design optimization – ongoing research focus on optimizing the design of spiral vibration damper. This aims to improve the effectiveness of vibration control. This includes studying factors such as the shape and dimensions of the dampers, spacing between dampers and attachment mechanisms to maximize damping efficiency.

Frequently asked questions

Spiral vibration dampers are devices used to control aeolian vibrations in ADSS cables. They help to reduce the amplitude of wind-induced cable vibrations. This helps to prolong the lifespan of the cables and ensure reliable performance.

Spiral vibration dampers are from high-strength, corrosion-resistant materials such as aluminum alloy or galvanized steel. These materials ensure durability and longevity in outdoor environments.

Advancements include material innovations, design optimization, integration with monitoring systems, customization and improved installation methods.