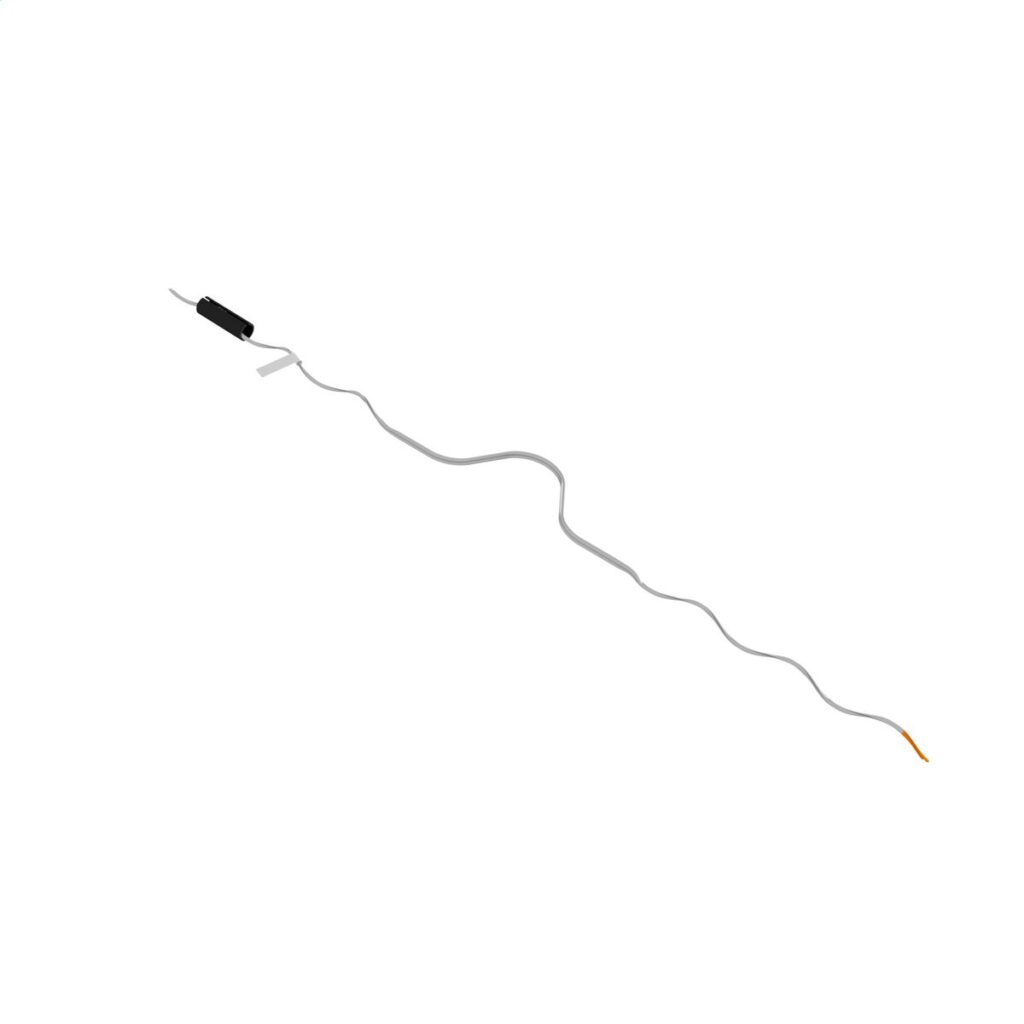

A spool tie is a specific type of accessory used to secure and support conductors on insulators. It serves in overhead transmission lines to ensure the stability and reliability. It is from a formed wire that provides a mechanical and electrical connection. The spool tie consists of several components such as the wire, insulator and band. Their design and functionality help to ensure the continuous and safe operation of the systems. Spool ties provide mechanical support, electrical continuity and insulation. Common types of spool ties include the preformed spool tie, armor grip spool tie and side and top tie. They serve purposes in maintaining conductor position, reducing wear and tear and ease maintenance.

Selecting the best spool tie

There are several types and designs of spool ties in the industry to select from. The selection process involves considering several factors. These helps to ensure optimal performance, safety and longevity of the system. Also, consideration of these factors help to ensure you select the spool tie that meets the specific needs of your project. The following are the factors to consider when selecting the spool ties.

- Conductor size and type – the spool tie must fit the specific diameter of the conductor. The conductor’s material should match the spool tie to avoid galvanic corrosion.

- Insulator type – there are different insulator designs which need specific types of spool ties. It is important to ensure the tie is compatible with the insulator’s shape and configuration.

- Environmental conditions – consider the weather conditions such as high winds, ice loading and temperature extremes. The ties should be durable enough to withstand these factors without failure. The ties should also have anti-corrosive properties to resist corrosion.

- Mechanical loads – check the mechanical tension that the tie need to withstand. High tension areas might need stronger and more robust spool ties. Select spool ties designed to reduce wear due to the movements.

- Electrical load – ensure the selected spool tie can handle the electrical current of the conductor without overheating. Consider the thermal properties of both the conductor and the tie to avoid issues.

- Cost and availability – balance the quality of the spool ties with the budget constraints. Higher initial costs should guarantee longer lifespan and reduced maintenance.

- Manufacturer reputation – select the spool ties from reputable manufacturers. They should produce high quality and reliable products.

- Installation and maintenance – choose the spool ties that are easy to install to reduce labor costs and downtime. Consider the ease of inspection and replacement to reduce maintenance time and cost.

Safety installation for a spool tie

Installation process for spool ties in overhead transmission lines ensure secure attachment of conductors to insulators. They provide mechanical stability and electrical continuity of the transmission system. Additionally, proper installation of spool ties is important for maintaining the integrity and safety of the overhead lines. The following is a step-by-step guide to the installation process for spool ties.

- Preparation and safety measures – wear suitable PPE such as gloves, safety glasses and hard hats to ensure personal safety. Ensure you have all the necessary tools required for the installation.

- Inspection and cleaning – check the insulator for any cracks or damage and the conductor for wear or corrosion. Use a cloth to clean the conductor and insulator to ensure there is no debris that could affect the installation.

- Selecting the correct spool tie – ensure the spool tie matches the conductor’s diameter and the insulator’s design.

- Conductor positioning – align the conductor on the insulator in the intended location. Ensure it is at the centre and aligned with the insulator.

- Attaching the spool tie – open the preformed spool tie and position it around the conductor at the insulator. Wrap the tie’s legs around the conductor following the natural form of the tie. For traditional spool ties, attach the tie wire to one side of the insulator and wrap the tie around the conductor and insulator in a spiral pattern.

- Securing and tensioning – ensure the spool tie is comfortable but not overtightened. The conductor should be secure without any excessive tension that might cause damage.

- Inspection and testing – check that the tie is properly installed with no visible gaps or loose ends. Perform electrical tests to ensure continuity and that there are no issues with resistance.

- Documentation – document the installation including the type used, location and any specific observations.

Maintenance and inspection practices for spool ties

Regular maintenance and inspection of spool ties helps to ensure the longevity and reliability of the systems. This helps to identify potential issues before they lead to failures. They also reduce downtime and improve the safety and efficiency of power distribution. Also, these practices ensure the spool tie remains in good condition and reduces the risk of outages. The following is a basic guide for maintenance and inspection for the spool tie.

- Inspection scheduling – conduct regular inspections at least once or twice a year. Perform extra inspections after events such as storms, hurricanes or heavy ice conditions.

- Visual inspection process – check the spool tie, conductor and insulator for corrosion, wear, damage, tightness and environmental impact. Use infrared cameras to detect hot spots that might indicated electrical resistance.

- Mechanical testing – perform tension tests to ensure the spool tie applies the correct amount of force to the conductor. Conduct tests to ensure the spool tie can withstand these conditions without loosening.

- Tightening and adjustments – check and tighten spool ties as necessary to maintain the proper tension and alignment.

- Cleaning – clean the spool tie, conductor and insulator to remove dirt, debris and corrosion build-up. This helps to maintain good electrical contact and reduce wear.

- Lubrication – apply suitable lubricants to moving parts to reduce wear and extend the life of the spool tie. Replace any damaged or worm spool ties to prevent failures.

- Technology integration – integrate advanced tools and technologies to enhance the inspection and maintenance process. This includes use of remote monitoring systems, smart sensors and data analytics.

- Documentation – keep detailed records of all inspections and maintenance activities. Create inspection reports that summarize findings and highlight critical issues.

Testing spool ties

Testing spool ties in overhead transmission lines helps to ensure their mechanical and electrical integrity. It includes various methods that assess the condition of the spool ties. It also helps identify any potential issues that could lead to failures. Additionally, these methods help to track the condition of spool ties and prevent power outages. The following are the different testing methods for spool ties.

- Visual inspection – identify the obvious signs of wear, corrosion or mechanical damage. Inspect the spool ties for corrosion, loose attachments and any deformations.

- Infrared thermography – this helps to detect hot spots that show high resistance or poor electrical connections. Use an infrared camera to scan the spool ties and related components.

- Ultrasonic testing – this is to detect internal flaws or cracks that are not visible externally. Use an ultrasonic testing device to send sound waves through the spool tie and insulator.

- Tension testing – ensure the spool tie applies the correct tension to the conductor using a tension meter to measure the force. The tension readings should match the specifications provided by the manufacturer.

- Electrical resistance testing – this is to check for proper electrical continuity and low resistance connections. Use a micro-ohmmeter to measure the electrical resistance of the spool tie connection.

- Vibration testing – check the spool tie’s ability to withstand mechanical vibrations from environmental factors. Use a vibration testing equipment to simulate the effects of wind, mechanical loads and other factors on the spool tie.

- Corona discharge testing – detect any corona discharge that may show insulation breakdown. Use the ultraviolet imaging device to detect and visualize corona discharges around the spool tie.

Community forums and interactions for spool tie

Engaging with community forums and interactions can be beneficial to professionals and enthusiasts. These platforms provide opportunities to share knowledge, ask questions and solve problems related to the ties. The following is a guide to finding community forums and interactions related to spool ties.

- Online forums and communities – these include Power Lineman Forums, industry-specific Subreddits, and professional Networking Sites.

- Technical Associations and Communities – these include IEEE Power &Energy Society and International Council on Large Electric Systems (CIGRE).

- Industry-specific websites and blogs – common ones include Transmission& Distribution World and Electrical Line Magazine.

- Social media and networking – this includes Facebook groups and Twitter like Power Lineman, Transmission Line Construction and use of relevant hashtags.

- Workshops and webinars – this includes workshops hosted by utility companies and industry associations to learn about best practices and innovations in spool ties.

Frequently asked questions

A spool tie is a device used to attach a conductor to an insulator in overhead transmission lines. Its main function is to maintain electrical and mechanical continuity. This is to ensure the conductor remains stable and properly aligned with the insulator.

The practices include routine inspections, visual checks, mechanical testing, electrical testing and documentation.

Common testing methods include visual inspection, infrared thermography, ultrasonic testing, tension testing and vibration testing.