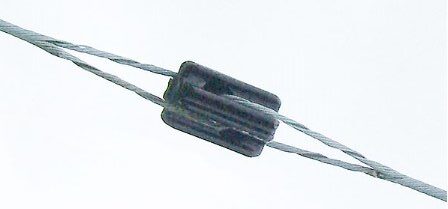

A stay insulator is an electrical insulator designed to provide electrical insulation and mechanical support to guy wires. It is also known as a stay strain insulator or a guy strain insulator. It provides electrical insulation for maintaining the integrity and safety. They also secure the guy wires to the supporting structure. This is while withstanding the mechanical stresses and tension loads on guy wires. They are from materials such as porcelain, composite or glass. These materials help them adapt to the different climate conditions in Southeast Asia. Common types include suspension type, bracket type, crossarm type and spool type stay insulators. They find use in applications such as transmission lines, distribution lines, telecommunication lines, wind turbines and high-tension power lines.

Key features of stay insulators

Stay insulators have various features that make them suitable for their role in electrical systems. The features ensure electrical insulation and mechanical support to the guy wires effectively. They ensure the insulator provides electrical insulation and mechanical support. This also helps them contribute to the safety and reliability of the electrical transmission. The following are the key features of the stay insulators.

- Electrical insulation – the insulators provide high electrical insulation resistance. This prevents the electrical current from flowing down the guy wire.

- Material – common materials for stay insulators include porcelain, composite or glass.

- Mechanical strength – the stay insulators have high mechanical strength. This is to withstand the mechanical stresses and tension loads on guy wires.

- Lightweight design – stay insulators are lightweight which makes them easier to handle and install.

- Corrosion resistance – stay insulators resist corrosion which ensures their long-term reliability.

- UV resistance – their design resists UV radiation from sunlight without degrading over time.

- Ease of installation – most insulators have features like mounting hardware and attachment points. These features make them easy and simple to install.

- Flexible design – their flexibility allows them to adapt to various angles and configurations.

- Ease of maintenance – they also have features that make inspection and maintenance easy when necessary.

Selection and installation of stay insulator

The selected stay insulator should be suitable for specific application and conditions. It should also ensure the safety, reliability and longevity of electrical transmission. Some of the factors to consider include voltage levels, mechanical load, material selection, standards and regulations, cost and installation. The installation of stay insulators depends on the type of stay insulator, configuration of the guy wires and local regulations. The following is a basic installation guide for stay insulators.

- Safety precautions – ensure to follow all the necessary safety protocols and isolate the work area.

- Inspection – inspect the stay insulators for any visible damage, cracks or defects.

- Guy wire preparation – ensure the guy wires are correctly tensioned and properly anchored to the support structure.

- Mounting hardware – assemble the necessary mounting hardware such as bolts, nuts and washers.

- Stay insulator attachment – attach the insulator to the guy wires using the provided attachments. Ensure the insulators are securely fastened and aligned.

- Positioning – position the stay insulators at the desired locations along the guy wires. This helps to ensure they can provide electrical insulation.

- Tightening and torquing – use the torque wrenches to tighten the fasteners. This is by following the manufacturer’s recommended torque specifications.

- Inspection – conduct a final visual inspection of the installed stay insulators. This is to ensure they are correctly aligned and securely fastened.

- Documentation -keep detailed records of the installation. These is including date, location, type and other observations.

Maintenance and inspection of stay insulator

Stay insulators require regular maintenance and inspection to ensure their continued performance. This also helps identify and address issues such as contamination, damage or wear. These conditions may compromise the insulators functionality. Additionally, it is advisable to consult experts for evaluation and guidance. The following is a basic guide on the maintenance and inspection of the stay insulators in Southeast Asia.

- Conduct visual inspections of the stay insulators to check for any visible signs of damage, contamination or wear. Check for contaminants such as dirt, dust, pollution or vegetation on the insulator surface.

- Assess the pollution levels on the insulator surface to reduce flashovers.

- Inspect the mechanical components of stay insulators such as brackets, fasteners and attachments. This is to ensure they are securely fastened and free from damage or corrosion.

- Consider the environmental conditions of the installation site. These include humidity, temperature fluctuations and UV exposure.

- Verify the tension and condition of the guy wires the stay insulators will support.

- Clean contaminated insulators using the recommended methods and materials. Avoid abrasive cleaning methods that may scratch or damage the insulator material.

- Establish a periodic inspection schedule based on the environmental conditions and manufacturer recommendation.

- Maintain records of inspection dates findings and any maintenance or cleaning activities.

Comparative analysis of stay insulator in Southeast Asia

A comparative analysis involves comparing and contrasting various types and designs of stay insulators. There are various factors that influence the decision-making process for the stay insulators. These factors include the types of insulators available, material choices, environmental challenges and regulatory considerations. The following is a comparative analysis for stay insulators in Southeast Asia.

- Types of stay insulators – stay insulator are from different materials that make them lightweight, pollution-resistant and suitable for a wide range of voltage levels. These include materials such as porcelain and composite insulators. The demand is increasing in Southeast Asia due to the tropical climates in the regions.

- Environmental considerations – may parts of Southeast Asia experience high humidity and pollution which requires stay insulators that are pollution-resistant.

- Material selection – composite materials are popular for their lightweight nature, pollution resistance and long service life. Porcelain materials are durable and strong but may require more frequent cleaning and maintenance in polluted regions.

- Cost and performance – balance the cost and performance of the stay insulator depending on the budget constraints.

- Voltage levels – stay insulators work in a range of applications in Southeast Asia from low to high voltage transmission lines.

- Local manufacturing – the local manufacturing in Southeast Asia influences the market availability and pricing.

Certifications and standards in Southeast Asia

There are various specific standards and regulations for stay insulators in Southeast Asia. They however, vary from country to country within the region. Most of the countries in the region adopt international standards for electrical equipment. Additionally, manufacturers and suppliers in the region should work with the local regulatory authorities. This is to ensure their products meet the relevant standards and certification requirements for each market. The following are the common standards and certifications applicable to stay insulators.

- IEC standards – these are standards for electrical equipment including insulators to ensure safety.

- ANSI standards – these are American standards set for various electrical equipment such as insulators.

- EN standards – these are European Norm standards used for the conformity assessment.

- ISO standards – these are standards related to electrical insulating materials and testing methods.

- Product certification – the products may undergo product certification by recognized certification bodies in respective countries.

- Local regulatory standards – each country in this region have their own national or local standards and certification requirements for electrical equipment.

Regional market for stay insulator in Southeast Asia

There are various factors that influence the regional market for stay insulators in southeast Asia. Manufacturers and suppliers need to be up to date with the latest news the market is always changing due to various dynamics. Some of these factors include energy demand, infrastructure development, environmental conditions and compliance. The following are the common factors that shape the regional market for the stay insulators in Southeast Asia.

- Energy demand – increased energy demand in the region is from the population growth, economic development and urbanization.

- Infrastructure development – investments in infrastructure development includes the expansion of power generation capacity and transmission lines. this development leads to the increased demand for stay insulators.

- Pollution resistance – pollution-resistant stay insulators are necessary due to the pollution-related flashovers. These are from industrial emissions and contaminations.

- Renewable energy integration – increased renewable energy integration requires the expansion and reinforcement of transmission lines.

- Market competition – the southeast Asian market is competitive in terms of stay insulators. This is from both the local and international manufacturers.

- Investment in smart grids – investing in smart grid technology improves the efficiency and reliability of their power systems. this leads to the increased demand for transmission lines and hence for stay insulators.

- Environmental conditions – the diverse environmental conditions from tropical climates with high humidity and salt contamination requires the use of pollution-resistant composite insulators.

Frequently asked questions

This is an electrical insulator designed to provide electrical insulation and mechanical support to guy wires in overhead transmission systems.

Southeast Asian countries mostly use composite insulators, porcelain insulators and glass insulators. The selection depends on the voltage levels, pollution levels and environmental conditions.

The key factors include voltage level, pollution levels, regulatory compliance, mechanical load and long-term durability.