A stay rod is also known as a guy wire or a guy rod which is a tensioned cable used to provide stability and support. It supports structures such as utility poles, towers, masts and antennas. Stay wire prevents the supported from bending or leaning in areas with high winds or lateral forces. It is from materials such as steel or fiberglass. These materials help them to withstand these adverse environmental conditions. A stay rod installs diagonally from the upper portion of the structure to a ground anchor. They are commonly used in applications such as distribution systems, telecommunications, radio towers, flagpoles and guyed masts.

Components of stay rods

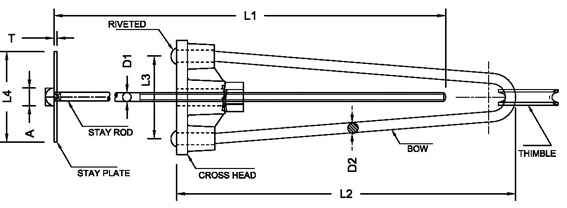

There are various components of the stay rod that help to bring the stability to the supported structure. The available components vary depending on the application, load requirements and local regulations. Stay rods have different designs and variations that help to meet specific needs and conditions. The following are the main components of the guy wire.

- Rod – this is the main components of the stay rod made of steel or other high strength materials to withstand tension. The rod threads on both ends to facilitate the connection and adjustment to provide structural support.

- Clevis – this is a fitting attached to one end of the stay rod and help connect it to the main structure.

- Turnbuckle – this is a component that allows for tension adjustment which has two threaded ends connected by a body with a screw mechanism.

- Dead-end anchor – this is a device used to securely anchor the opposite end of the stay rod. It can be concrete anchor block or ground anchor to ensure the stay rod remains fixed in place.

- Fasteners – fasteners such as nuts, bolts, washers, pins and other hardware connect and secure the components of the stay rod system.

Types of stay rod

There are various types of high strength stay rods used for different applications in the industry. The choice of the stay rod depends on factors such as specific application, load requirements, environmental conditions and industry standards. It is advisable to consult with professionals in the industry for guidance on the best stay rod for your particular application. There are two main types of stay rods which include:

Bow stay rod – these types of stay rods have a bent section in the middle that helps to distribute the load from the stay wire. They work in applications with high risk of excessive loads. Examples of these stay rods include fiberglass stay rods and dyform stay rods.

Tubular stay rod – this is a straight rod that encloses in a duct to protect the stay rod from corrosion. It also helps to distribute the load from stay wire evenly. They work in applications with high risk of exposure to moisture or corrosive materials. They include steel stay rod, strand stay rods and pre-stressed stay rods.

Applications of stay rods

Stay rods help to provide additional support and stability to structures in different applications. This helps reduce sway and prevent structural failure. Additionally, stay rods ensure proper tensioning, alignment and adherence to applicable engineering standards and regulations. The following are the main application areas of the guy wires.

- Telecommunication towers – guy wires provide stability and prevent extreme sway and help them withstand wind forces and vibration.

- Utility poles – stay rods help stabilize utility poles in high winds, seismic activity or uneven landscape to ensure the integrity of the power distribution or telecommunication networks.

- Antenna masts – stay rods work in antenna masts used for radio broadcasting or wireless communication. This helps to stabilize the masts and maintain required antenna alignment for ideal signal response and transmission.

- Structural support – guy wires apply in various structural applications that require additional support and stability. This includes supporting signage, lighting, fixtures, canopy structures, bridges and other tall structures.

- Transmission towers – stay rods support transmission towers by providing adjacent stability to the towers. This helps them withstand wind loads, ice loads and other external forces.

- Wind turbines – guy wires provide stability and support to the turbine tower which helps it withstand the dynamic loads for safe and efficient operations.

- Flagpoles – guy wires help to stabilize the pole and prevent extreme swaying which ensures the flagpole remains upright and visible.

Installation process of stay rod

Installation of the stay wires involves a series of steps used to ensure proper tensioning and secure attachment. It is advisable to follow manufacturer’s instructions and installation guidelines for proper and safe connections. Additionally, it is advisable to consult with qualified personnel to ensure proper installations and tensioning of the stay rods. The following are the basic steps followed during installation of stay rods.

- Determine the appropriate location and angles of installing the stay rods. Also identify the anchor points and the points of attachment on the structure.

- Clear the area of installation and ensure a stable foundation and install the anchor hardware such as dead-end anchors or ground anchors securely to the ground.

- Attach the suitable fittings such as clevises and turnbuckles to the stay rods. Ensure proper alignment and threading of the fittings.

- Position the structure to support in the desired location and attach one end of the stay rod to the selected attachment point on the structure. Ensure the attachment is secure and properly aligned with the structure.

- Apply tension to the stay rod using the suitable tools and adjust the tension in the stay rod to the required specifications. Ensure the tension in the stay rod distributes evenly to avoid stress concentrations.

- Inspect all the connection, fittings and hardware to ensure proper and secure connections. Make any adjustments if necessary to achieve the desired stability and support.

Selecting the best lightweight and flexible stay rod for your applications

There are various factors to consider when selecting the stay rods for your applications. The different types and designs of the stay rods help to meet different specific requirements of the application. It is advisable to consult with engineers and professionals in the industry to ensure the suitable stay rod meets the specific requirements. The following are the key factors to consider during the selection process.

- Consider the initial cost of the rods, installation requirements and long-term maintenance needs.

- Consider the tensioning system working with the stay rod which includes tensioning devices, hydraulic tensioners and turnbuckles. The stay rod should be compatible with the selected tensioning mechanism.

- Determine the maximum expected load to support including wind loads, ice loads, seismic activity and other forces.

- Assess the environmental conditions and consider factors such as exposure to corrosion, UV radiation, chemicals or extreme temperatures. The selected stay rod should withstand these conditions.

- Consider the manufacturer’s reputation who should have a track record of producing high quality products. They should also provide reliable customer service.

- Consider the diameter and length of the stay rod and select based on the structural requirements and engineering calculations for the application.

- Ensure the selected stay rod conforms with relevant industry standards, building codes and regulatory requirements.

- Consider the specific needs of the application to determine the material of the stay rods which should be from materials such as fiberglass or steel. These materials provide high strength and durability.

Frequently Asked Questions

A stay rod is a metal rod used to connect a stay wire to a ground anchor. It also provides extra support and stability to structures to prevent leaning or bending.

Telecommunications infrastructure

Radio towers

Flagpoles

Railway stations

Transmission towers

Wind turbines

Structural supports

Load distribution

Enhanced resilience

Increased safety

Cost effective

Easy installation and maintenance

Flexibility and adjustability

Periodic maintenance and repairs

Tensioning challenges

Environmental constraints

Requires expertise in engineering

Interference with other structures

Space and aesthetic considerations