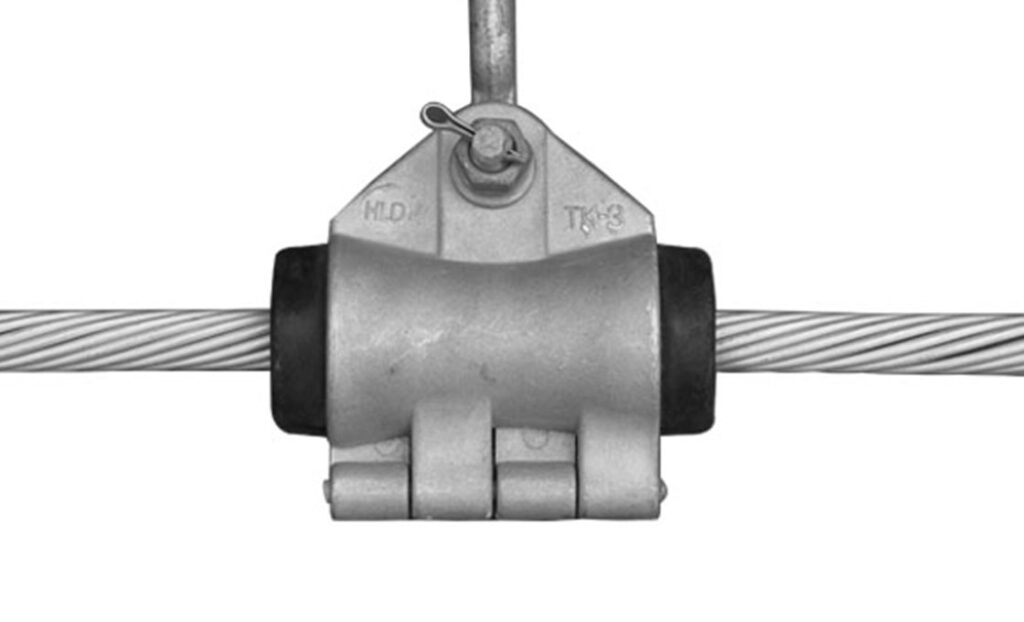

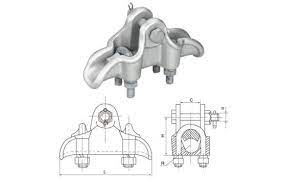

A suspension clamp is a device used to give conductors both physical and mechanical support. It helps maintain the proper tension and alignment of conductors. This is to ensure the reliability and safety of transmission structures. It enhances the safety of the conductor by limiting their movement against a strong wind and storms. Suspension clamps are available in different designs and sizes. This helps to accommodate different conductor types and sizes. It installs ate regular intervals along the length of the transmission line. Use of high-quality suspension clamps is crucial in the diverse weather conditions in South America. Common types include bolted, socket clevis, wedge-type, yoke plate and preformed suspension clamps. They find use in applications such as transmission lines, telecommunications and railway electrification.

Key features of suspension clamp

Various features of the suspension clamp help to ensure reliability, safety and alignment of conductors and cables. These features vary depending on suspension clamp type and design. The following are the key features of the suspension clamp.

- Material – suspension clamps are from high-strength materials like steel, aluminum or composite materials.

- Tension-control mechanism – it has design to control the tension in conductors or cables. This helps to prevent sagging and ensure proper alignment.

- Insulating properties – suspension clamps have insulating features. They help to prevent electrical contact between the conductor and supporting structure.

- Adjustability – some of the clamps allow for adjustability. This allows for fine-tuning during installation.

- Ease of installation – they have simple features that allow for easy installation. These include attachment points for insulators and other hardware.

- Corrosion resistance – the clamps may have corrosion-resistant coatings.

- Load bearing capacity – the clamps are able to accommodate specific loads and conductor sizes. This is to safely support the weight of the conductors

- Anti-galloping and vibration damping – they have features that mitigate conductor galloping.

- Environmental compatibility – they have designs that withstand various environmental conditions. These include exposure to UV radiation, extreme temperatures and moisture.

- Cost effectiveness – the clamps offer a cost-effective solution for maintaining the stability and reliability of overhead transmission lines.

Selection and installation of suspension clamp

The selection of suspension clamps involves evaluation of various factors. These factors include project requirements, conductor type and size, load calculation, corrosion resistance, alignment needs and costs. The installation process should ensure the safe and reliable support of conductors or cables. Additionally, it is advisable to consult with industry experts for guidance on the best installation guide. The following is a general installation guide for the suspension clamp.

- Preparation – ensure you have all the tools and equipment required for the installation. Ensure the workers are fully equipped with personal protective equipment.

- Conductor attachment – position the suspension clamp at the desired location on the conductor.

- Alignment – ensure the conductor and suspension clamp aligns correctly. This is to ensure the performance and longevity of the suspension system.

- Bolting – secure the suspension clamp around the conductor. This is by fastening the clamps halves together using fasteners.

- Insulator attachment – attach the insulators to the suspension clamps. This helps to electrically isolate the conductor.

- Pre-tensioning – apply pre-tension according to the manufacturer’s guidelines. This helps to ensure the conductor tensions and no sag is present.

- Inspection – conduct a visual inspection of the installed suspension clamp. This is to ensure proper security and alignment. Check for any signs of damage or issues that require attention.

- Documentation – keep records of the installation including photographs and tension measurements.

Maintenance and inspection of suspension clamp in South America

Proper maintenance and inspection ensure the continued reliability and safety of the system. The frequency of the installation varies depending on environmental conditions, conductor type and load bearing capacity. It also helps identify and address potential issues. This is before they cause accidents and electrical hazards. The following is a basic guide for the maintenance and inspection of suspension clamps.

- Perform routine visual inspections of all suspension clamps. Check for signs of damage, corrosion, loose bolts and other issues.

- Inspect the clamps for signs of corrosion especially in areas with high humidity or salt exposure.

- Ensure the alignment of the conductor, insulators and supporting structure is correct.

- Verify that vibration dampening and anti-galloping devices are operational.

- Measure the tension of the conductors using suitable tensioning tools. Ensure the tensions are within specifications.

- Clean, repaint or replace corroded components in case any corrosion presence.

- Replace any damaged or loose bolts to ensure the secure attachment od suspension clamps to conductors.

- Replace any damaged or compromised components of the suspension clamp. This is to maintain the integrity of the suspension system.

- Re-tension any sagged conductors to the specified level to maintain alignment and performance.

- Maintain records of all inspections, maintenance and repairs of the suspension clamps. This includes dates and descriptions of work performed.

Comparative analysis of suspension clamp in South America

A comparative analysis involves assessing the various suspension clamps available in the region. This includes considering factors such as performance, design, durability and suitability for different applications. The analysis should depend on the specific needs and conditions of the project in south America. Additionally, it is advisable to include experts in the analysis for the best decision. The following are the factors to include in the comparative analysis in South America.

- Load bearing capacity – assess the load bearing capacity of different suspension clamps. This is to ensure they are capable of supporting the weight and tension requirements of conductors.

- Adjustability – evaluate the adjustability and availability of customization options.

- Types and varieties – compare the types and varieties of suspension clamps. Consider options for power transmission, telecommunications and wind energy.

- Alignment – consider the design features that promote proper alignment and reduce conductor vibrations.

- Ease of installation – compare the ease of installation of different suspension clamp types.

- Environmental compatibility – assess how well the suspension clamps can withstand the specific environmental conditions.

- Material and corrosion resistance – compare the materials used in suspension clamps. The materials include steel, aluminum or composite materials.

- Cost effectiveness – consider the cost-effectiveness of different suspension clamp options. Balance between cost, quality and performance.

- Local availability – determine the availability of suspension clamps from local sources. This is because it affects lead time and project logistics.

- Maintenance requirements – compare the maintenance needs of different suspension clamps types. This is to ensure they align with the available resources for upkeep.

Certifications and standards in South America

There are various standards and regulations that govern the use of suspension clamps in South America. The standards and certifications help to ensure safety and performance of the suspension clamps. Additionally, it is advisable for manufacturers and suppliers to adhere to local regulations. The standards vary from country to country and others adopt to the international standards. The following are the standards and certifications in South America.

- IEC standards – this provides a set of international standards for electrical and electronic technologies.

- ASTM international standards – this provides a range of standards for materials, products and systems. They also include hot dip galvanizing and zinc coatings.

- IEEE standards – this offer standards for electrical and electronic technologies. This includes vibration dampers and suspension clamp components.

- Local regulations – suspension clamps must comply to local electrical and safety regulations specific to each country.

- ISO certification – these are certifications for quality and environmental management systems.

- Quality assurance certifications – certifications from quality assurance organizations indicate the clamps meet certain performance and safety standards.

- Environmental impact standards – suspension clamps should meet standards for materials and coating with minimal environmental impacts.

Regional market for suspension clamps in South America

There are several market dynamics that influence the regional market for suspension clamps in South America. South America’s diverse landscape and unique environmental conditions influence the demand for suspension clamps. Also, manufacturers and suppliers should evaluate the market trends to gain the success in the market. The following are the common factors that shape this regional market.

- Telecommunications – improvement of mobile networks and broadband connectivity increases the demand for the clamps.

- Coastal regions – the exposure to saltwater and high humidity demand suspension clamps with corrosion resistance. This helps to improve the longevity of overhead transmission lines and communication infrastructure.

- Urbanization – the expansion of electrical and telecommunication networks require use of streetlighting and traffic signals. This hence requires the use of suspension clamps for improved support.

- Local manufacturing and supply – the availability of local manufacturers and suppliers promotes self-sufficiency and supports regional market.

- Wind energy – investments in wind farm projects requires the use of suspension clamps which grows the demand.

- Regulatory compliance – each south American country has their own set of standards and regulations for the use of suspension clamps.

Frequently asked questions

A suspension clamp is a component used to support and suspend electrical conductor r cables in overhead transmission lines. It helps to maintain proper tension, alignment and stability of the conductors. This also helps to ensure the reliable transmission of electricity.

Selecting the most suitable suspension clamps involves considering several factors. These factors include conductor size, load capacity, environmental conditions and specific application requirements.