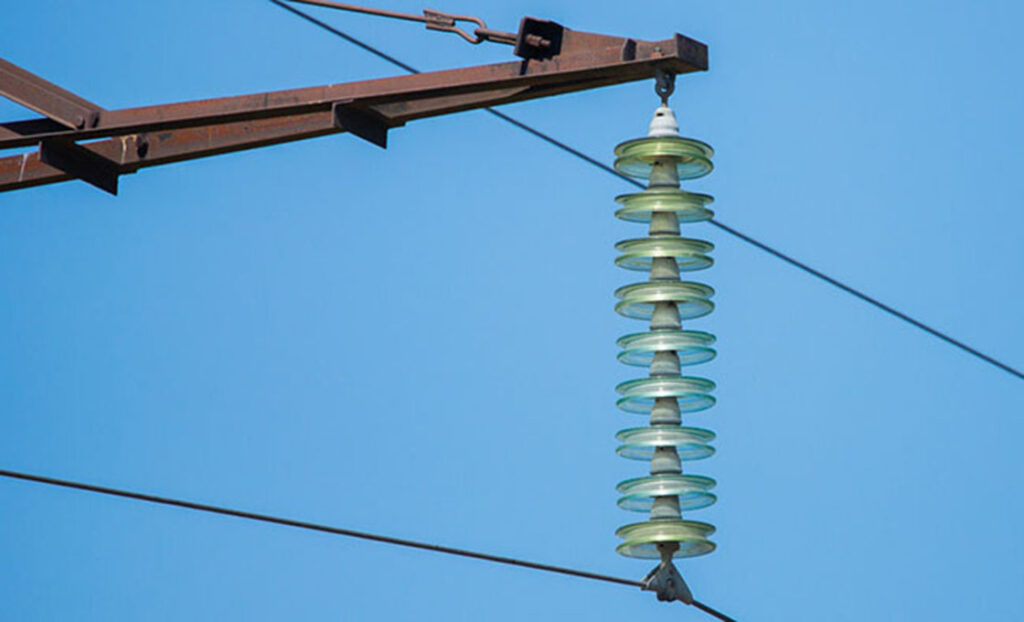

A suspension insulator is a component used to support conductors while providing insulation. It consists of an insulating core made of materials such as porcelain, glass or composite. It installs in a suspended form from a supporting structure and supports the electrical conductor. This is while preventing the flow of electric current from the conductor to the support structure. Suspension insulators ensures the integrity and safety of the electrical installation. This is by maintaining electrical insulation and mechanical support. Suspension insulators work in ADSS and OPGW cables in various applications. They provide mechanical support, electrical insulation, spacing and sag control. They provide lightning protection to ensure the safe and reliable operation of the systems. Common types of the insulators include cap and pin, interlink and material-based suspension insulators.

Materials used in manufacture of suspension insulator

Suspension insulators are from materials that provide mechanical strength and electrical insulation. The selection of the material depends on various factors. These include operating voltage, environmental conditions and mechanical loads. Each of these materials provide properties that contribute to their performance and reliability. The following are the common materials for suspension insulators.

- Porcelain – this material provides electrical insulation properties and mechanical strength. Porcelain insulators are from high-strength clay, feldspar and quartz fired at high temperatures. They are able to withstand applications with various environmental conditions and voltage levels.

- Glass – the insulators are from toughened or tempered glass. This provides good mechanical strength and resistance. Glass insulators work in areas with high pollution levels or coastal environments.

- Composite materials – composite suspension insulators are from fiberglass plastic or silicone rubber. The materials offer benefits like lighter weight, mechanical strength and better pollution resistance. They work in areas with heavy pollution, coastal regions or areas prone to vandalism.

- Metal components – galvanized steel or aluminum help provide strength and durability. Metal end fittings attach to the insulating core to support the conductor and connect the insulator to the support structure.

Technical specifications for suspension insulator

Technical specifications for suspension insulators vary depending on various factors. Considering these factors help to select suspension insulators that meet the specific requirements. Additionally, it is advisable to ask for specifications from manufacturers for best selection. The following are the technical specifications for suspension insulators.

| Universal Model | U160B/170 | U160B/155 | U160B/146 |

| ( mm ) Diameter | 280 | 280 | 280 |

| ( mm ) Height | 170 | 155 | 146 |

| ( mm )Leakage distance | 400 | 400 | 400 |

| ( mm )Coupling | 20 | 20 | 20 |

| ( kN ) SML | 160 | 160 | 160 |

| ( kN )Tension Load Test | 80 | 80 | 80 |

| ( kV )Power frequency Withstand wet | 45 | 45 | 45 |

| ( kV )Lightning Impulse Withstand | 110 | 110 | 110 |

| ( P.U )Puncture Impulse Voltage | 2.8 | 2.8 | 2.8 |

| ( kV )Puncture power frequency voltage | 130 | 130 | 130 |

- Voltage rating – the insulators are available in various voltage ratings to suit different applications. They work in voltage rating including low voltage and medium voltage. They also work in high voltage, extra-high voltage and ultra-high voltage. The rating determines the insulator’s ability to withstand electrical stress without breakdown.

- Mechanical strength – they should have enough strength to support the weight of the conductors. Specifications include tensile strength, compression strength, bending strength and impact resistance.

- Dimensional specifications – the insulators have specific dimensional requirements. This is including length, diameter, shed profile and fitting dimensions. The specifications help to ensure the reliable operation of the transmission line.

- Creepage distance – this is the shortest path along the surface of the insulator between the conductor attachment point and support structure. A long creepage distance helps to prevent tracking or surface leakage currents.

- Material composition – consider the material composition of the insulating core and other components. The composition affects properties such as electrical insulation, pollution resistance and durability.

- Corona performance – Insulators with good corona performance helps reduce energy losses, reduce electromagnetic interference and ensure reliable operation of the line.

Industry advancements and updates for suspension insulators

There have been several advancements and updates in the suspension insulator industry. They aim at improving performance, reliability and sustainability. Additionally, it is advisable to consult with experts for guidance on the updates for suspension insulators. The following are the industry advancements and updates for suspension insulators.

- Composite materials – there is an increase in the use of materials like fiberglass reinforced plastic and silicone rubber. These materials provide benefits such as lighter weight, higher mechanical strength and better pollution resistance.

- Integrated monitoring systems – some of the insulators have integrated monitoring systems that provide real-time data. This is data on insulator performance, temperature, humidity and pollution levels. The systems help utilities to detect potential issues early, optimize maintenance schedules and improve reliability.

- Smart insulator technologies – there is development efforts to integrate smart technologies into the insulators. These include embedded sensors, communication capabilities and self-diagnostic systems. The technologies enable monitoring, predictive maintenance and remote management of transmission line assets.

- Standardization and certification – there are efforts made to standardized suspension insulator specifications. This is to ensure consistency, interoperability and quality across different manufacturers and regions. Standardization helps to select insulators that meet specific performance and reliability requirements.

- Advanced shed designs – manufacturers have advanced shed designs for suspension insulators. This is to enhance pollution performance and reduce the risk of flashovers in polluted environments. These designs include improved shed profiles, hydrophobic coatings or surface treatments.

- High voltage application – increased demand for high voltage transmission lines increases focus on developing insulators with higher voltages. There is continuous development to meet the requirements of extra-high voltage and ultra-high voltage applications.

- Environmental sustainability – there is incorporation of environmental sustainability into the design and production. This includes using eco-friendly materials, reducing energy consumption during manufacturing processes.

Advantages and disadvantages of suspension insulators

Suspension insulators provide many benefits like performance, reliability and durability. The insulators also face various challenges in their use. These include pollution performance, mechanical stress and environmental degradation. The following are the advantages and disadvantages of suspension insulators.

Advantages

- Electrical insulation – the insulators prevent the flow of current from the conductor to support structures. This ensures the integrity and safety of the transmission line. This is by maintaining electrical insulation.

- Durability – insulators are able to withstand harsh environmental conditions to ensure long-term performance. They are able to resist high winds, temperature fluctuations, pollution and UV radiation.

- Cost-effectiveness – the insulators are cost effective for transmission lines compared to other methods. They need minimal maintenance and have a long service life to reduce operational costs.

- Mechanical support – the insulators support the weight of the conductors and withstand mechanical stresses.

- Versatility – insulators work in a wide range of voltage levels and environmental conditions.

- Ease of installation – the insulators have designs for easy installation and replacement. This helps reduce downtime during construction.

Disadvantages

- Pollution performance – pollution buildup can compromise their insulating properties which leads to tracking.

- Mechanical stress – the insulators face mechanical stresses in their applications. This is including wind, ice, conductor tension and vibration. This can lead to fatigue failure, cracking or breakage of insulator components. This may in turn compromise their structural integrity and reliability.

- Vandalism and wildlife interactions – suspension insulators are prone to vandalism or damage by wildlife. This can lead to power outages, equipment damage and safety hazards.

- Aging infrastructure – existing suspension insulators need replacement to maintain reliability and safety.

- Environmental conditions – the insulators must withstand a wide range of environmental conditions. This is including temperature extremes, UV radiation, moisture and seismic events.

Differences between a disc insulator and a suspension insulator

A disc insulator and suspension insulators are both used in transmission and distribution lines. Disc insulators consist of a stack of ceramic or glass discs with a metal pin passing through the center. The discs arrange in a vertical or horizontal orientation. Suspension insulators are longer and consist of a series of insulating units connected in a string. Each unit has a cap and pin arrangement with the conductor attached to the bottom pin. Disc insulators work in low to medium voltage distribution lines and substation applications. Suspension insulators work in medium to high voltage transmission lines.

Frequently asked questions

Disc insulators are compact and consist of stacked ceramic or glass discs with a central metal pin. It works in low to medium voltage applications. Suspension insulators are longer strings of insulating units with a cap and pin arrangement.

The voltage rating of suspension insulators depends on factors like material composition, creepage distance, pollution performance and mechanical strength.