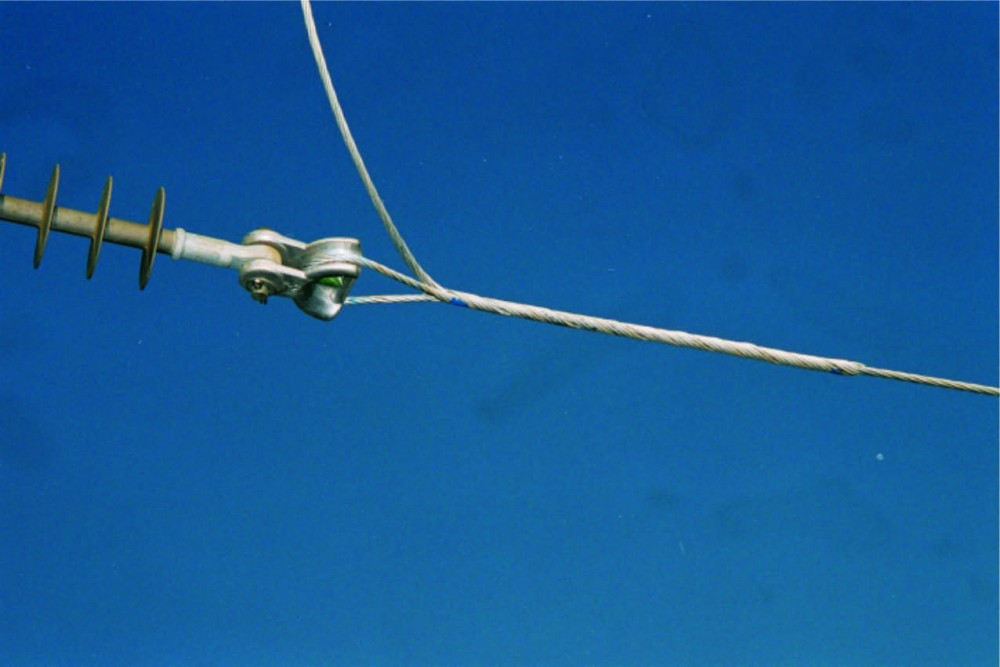

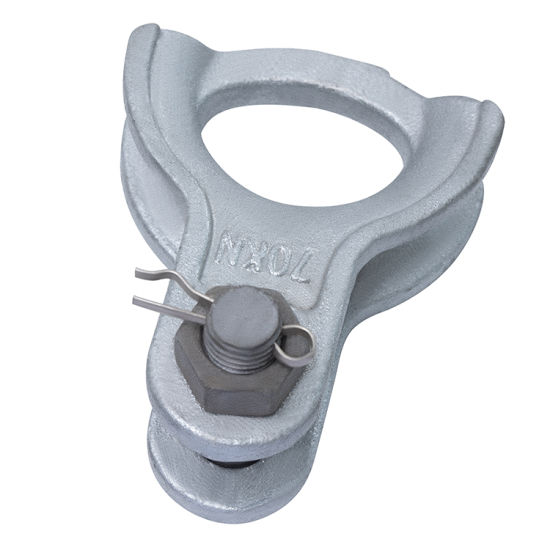

A thimble clevis is a component used for attaching insulators to the line conductor in overhead transmission lines. It also helps to connect the conductor to the insulator strings which support the conductors. It consists of a thimble-shaped metal component with a groove at one end to accommodate the conductor. The other end of the clevis features a pin that secures it to the insulator. Thimble clevises are able to withstand the mechanical forces and environmental conditions. This ensures the secure attachment of conductors to insulators while allowing some movement. It also helps to accommodate the expansion and contraction due to temperature changes. Thimble clevises work in overhead transmission lines, construction and electrical infrastructure.

Features of the thimble clevis

Thimble clevises provide secure attachment points for conductors to insulators. They have several features working together to meet the requirements of the application. The following are the features of the thimble clevis.

- Thimble shape – the clevis has a cylindrical body and a loop at one end to accommodate the conductor.

- Attachment point – thimble clevis has a secure attachment point for the conductor. It is often in the form of a loop, groove or hole designed to fit the specific size of the conductor.

- Adjustability – the clevises offer some degree of adjustability to accommodate various conductor sizes. It also helps to compensate for line sag or tension.

- Load capacity – the clevises have ratings for specific load capacities to ensure they can support the weight of the conductor.

- Inspection points – some of the clevises have features like inspection holes to allow for visual inspection of the attachment point. They also help ensure proper installation and maintenance.

- Material – the clevises are from high-strength, corrosion-resistant materials such as steel or aluminum. This ensures durability and longevity in harsh environmental conditions.

- Secure fastening – the clevises have designs to fasten to the insulator or other hardware using a pin, bolt or other means of attachment. This ensures the conductor remains in place even under high mechanical loads.

- Compatibility – thimble clevises has designs to be compatible with standard insulators. This ensures easy installation and compatibility with existing infrastructure.

- Corrosion resistance – the clevis also has coatings to provide extra corrosion resistance. This is to protect them from the elements and extend their lifespan.

Importance of using thimble clevis

Using thimble clevises help to ensure the safety and reliability of electrical infrastructure. They also contribute to compliance with industry standards and regulations. The following is the reasons to use thimble clevis in your application.

- Secure attachment – the clevises provide a secure attachment for conductors to insulators. This ensures the conductors remain in place even under high mechanical loads and environmental conditions.

- Safety – using thimble clevises enhances the safety of attaching conductors to insulators. It reduces the risk of conductor movement or failure which may be risky to workers and the public.

- Longevity and infrastructure – thimble clevises contribute to the longevity of overhead transmission lines. they help prevent premature wear and tear on components.

- Ease of maintenance – the clevises have designs providing easy installation and maintenance. This design allows quick replacement and reducing the downtime and maintenance costs.

- Damage prevention – the clevises help prevent damage to the conductor and insulator. This is by providing a smooth and secure attachment point.

- Line integrity – thimble clevises help maintain the integrity of the overhead transmission line. This is by ensuring the conductors are well supported and positioned. This helps to maintain the lines electrical performance and reliability.

How to select the best clevises for your application

There are different types and designs of the thimble clevis used for transmission lines. They are also from different manufacturers with different specifications for transmission lines. t is important to consider several factors to ensure compatibility, reliability and performance. Additionally, it is advisable to choose the best thimble clevis that meets the specific requirements of your transmission line. The following are the main factors to consider when selecting the thimble clevis.

- Check the conductor size and type to ensure compatibility on the transmission lines.

- Check the mechanical load requirements of the transmission line like tension, weight and environmental conditions.

- Consider the material and coating of the clevis like steel and aluminum. They should have the properties to resist rust and corrosion for longevity.

- Assess the design features of the thimble clevis like adjustability for tensioning or accommodating angular movement.

- The thimble clevis should be compatible with other hardware components in the transmission line system. This is including suspension insulators, yoke plates or pole fittings.

- Check if the reputation and track record of the manufacturer or supplier of the thimble clevis.

- The thimble clevis should follow industry standards and certifications. It should adhere to the recognized standards that help ensure the quality, safety and reliability of the thimble clevis.

- Consider the specific pecifications provided by the utility company or project engineers.

Safe installation of thimble clevises

The installation process of the thimble clevis depends on the design of the clevis, transmission structure and other specific requirements provided. Also, it is advisable to follow the guidelines and instructions provided for the specific thimble clevis to install. The installation of the thimble clevis on the transmission lines involves several steps discussed below.

- Preparation – ensure that you have the necessary equipment, tools and safety gear. Review the project specifications and instructions provided by the manufacturer.

- Clevis inspection – inspect the thimble clevis for any defects, damage or irregularities that affect performance. Prepare the conductor by removing any debris, corrosion or surface contaminants that may affect the installation.

- Thimble clevis attachment – place the thimble inside the clevis to ensure it is securely positioned. Align the holes or slots in the clevis with the attachment points on the transmission line structure.

- Conductor connection – insert the conductor into the loop, grove or hole of the thimble clevis. Ensuring a secure and proper fit to ensure proper alignment within the attachment point.

- Fastening – tighten the bolts or fasteners using the appropriate tools like wrenches or socket sets. Follow the recommended torque settings provided by the manufacturer or utility company. This is to ensure proper fastening without over-tightening or damaging the components.

- Check and adjust – inspect the installation to ensure the thimble clevis is properly aligned, attached and free from any visible defects. Check that the conductor positions within the thimble and that there is enough clearance and no signs of strain.

- Insulation – install any insulation covers on the thimble to provide extra electrical insulation. It also provides protection against environmental factors.

- Quality control – conduct quality control checks to verify that the installation meets the required standards and specifications.

Maintenance guide for thimble clevis

Regular maintenance of thimble clevis ensures the continued reliability and safety of transmission lines. It also helps to identify and address potential issues that could lead to failures and accidents. The frequency of this activity depends on the environmental conditions of the installation areas. Also, it is advisable to conduct professional inspections once in a while. The following is a basic guide for maintenance and inspection of thimble clevises.

- Establish a routine maintenance schedule for thimble clevises depending on the environmental conditions.

- Conduct visual inspections of each thimble clevis looking for signs of wear, corrosion or damage.

- Ensure the thimble clevises are free from dirt, debris or contaminants and clean them to maintain performance.

- Check the torque of bolts to ensure they are tight to the manufacturers specifications to enhance the stability of the clevis.

- Inspect the cotter pins for signs of damage and replace any cotter pins if necessary.

- Confirm the alignment of the thimble clevis with the conductor and attached hardware.

- Inspect the insulator attachment points to ensure the insulators are securely connected and free from damage.

- Inspect the thimble clevises looking for cracks or signs of metal fatigue.

- Examine the bolts and nuts for wear, corrosion or damage and ensure the threads are in good condition.

- Inspect the cotter pins for proper installation and signs of wear or corrosion. Replace any cotter pins with signs of deterioration.

- Assess the thimble clevises for exposure to harsh environmental conditions. This is including UV radiation, moisture and salt.

- Conduct functional tests to simulate the conditions where the thimble clevises operate. It also involves applying controlled loads to verify their performance under stress.

- Maintain detailed records of each inspection and note any observations, repairs or replacements.

Frequently asked questions

A thimble clevis is a component used in overhead transmission lines to attach conductors to insulators.

Thimble clevises plays a crucial role in overhead transmission line by providing secure attachment points for conductors to insulators. They ensure the reliability and safety of the electrical infrastructure.

When selecting the thimble clevises, consider factors such as material, load capacity, size, adjustability, manufacturer reputation and cost versus value.

Thimble clevises provide a secure attachment point for conductors preventing them from becoming loose or detached.