Top ties are devices or methods used to secure and support conductors at the topmost point of a transmission tower or structure. Their purpose is to provide mechanical stability and ensure the conductors remain in place under various weather conditions. Top ties install at regular intervals along the span of the transmission lines. They are mostly from steel wire or synthetic materials and attach to the top of the tower. Top ties limit the lateral movement and swinging of the conductors during high winds or weather conditions.

Components of ties

Top ties have various designs available since they are from different manufacturers. The available components of the top ties depend on the specific requirement of the top tie, design and purpose in the applications. The following are the common components of a top tie.

- Suspension/Strain Insulators – these help to provide electrical insulation and mechanical support to the conductor attachment points on the tower.

- Conductor clamps – conductor clamps help to secure the conductors to the tower structure. They should withstand mechanical loads and tension forces experiences by the conductors.

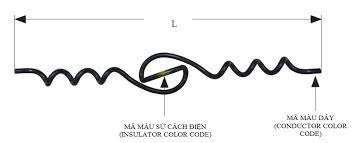

- Tension device – these devices include clamps and armor rods which help to distribute mechanical forces along the conductor. This helps in maintaining appropriate levels of tension.

- Vibration Damper – vibrations dampers help to mitigate the vibrations that occur in the in the conductors. This is due to environmental factors which reduces the stress on the conductors and preventing fatigue failure.

- Spacer Damper – spacer dampers help in bundled conductor configurations to maintain proper spacing. They also reduce the potential of galloping or aeolian vibration effects.

- Hardware Fittings – these includes bolts and nuts among other help to securely fasten and connect the different components.

Types of top tie

The type of the top tie selected depends on the specific requirement of the application and the intended use. The various types of top ties also depend on the manufacturer and suppliers of the devices. The following are the common types of top ties as used on the overhead transmission lines.

- Suspension type top ties help to support individual conductors in overhead transmission lines. They consist of insulators and conductor clamps to suspend the conductor from the tower structure.

- Tension type top ties help to maintain tension in the conductor and ensure proper sag and alignment. This is by using devices such as tension clamps and armor rods. They help to distribute mechanical forces along the conductor length.

- Bundle type top ties multiple conductors bundle together and support as a single unit. This configuration can enhance electrical performance and mechanical stability of the transmission line.

- Vibration damping top ties incorporate specific components such as vibration dampers. They help to mitigate effects of wind induced vibrations on the dampers.

- Strain type top ties help to anchor to terminate conductors at the end of the transmission line. This also provides mechanical support and secure the conductor to the tower structure using insulators and clamps.

Applications areas of top ties

The specific application of the top ties depends on the design and the available components of the top tie. It also depends on the voltage level, requirement of the project and environmental conditions of the area of application. The main application areas of the top ties are as discussed below.

- The primary application of top ties is to provide mechanical support and to secure the conductors to the transmission tower. It helps maintain proper alignment, sag and tension of the conductors ensuring reliable operation.

- Top ties assist in managing electrical loads carried by the electrical lines. This is by anchoring the conductors and maintaining proper tension levels. This helps distribute mechanical forces and loads evenly along the lines reducing risk of conductor sag or excessive stress.

- Top ties contribute to the stability of electrical lines by resisting wind induced movements, vibration and other external forces that can affect integrity and performance of the line.

- Vibration Dampers which are often included in top tie systems help dampen and reduce vibration. These occur due to wind and other environmental factors. This helps reduce risk of fatigue failure increasing the lifespan of the conductors.

- Top ties help protect the conductors from excessive movement and abrasions or contact with other structures. They maintain the required clearance preventing conductors from coming into contact with the tower components.

Installation guide of top ties

The installation process of the top ties depends on the specific design and requirements of the transmission line. The different manufacturers in the market may provide guidelines on how to install the top ties. It is also advisable to consult with different experts in the industry for guidance when in doubt.

- Prepare the installation site of the transmission tower or structure needs for the top tie system. This involves ensuring the tower is structurally secure and ease repair and maintenance.

- The components of the top tie assemble according to the manufacturer’s instructions. This include attaching necessary insulators clamps and dampers to the conductors.

- Identify the attachments points for the top ties identified on the transmission tower. They help withstand the mechanical forces exerted by the conductors and the top tie system.

- Position at the appropriate height and alignments ensuring the desired sag and tension levels. They help to the attachment points on the tower structure.

- The top tie components are securely attached and fastened to the tower structure.

- If the top tie system includes tension devices, they adjust to achieve the desired tension of the conductors. This helps maintain proper sag and alignments. Consider factors such as temperature variations and expected mechanical loads.

- Test the installation system to ensure proper functionality and mechanical stability.

Selection of the best top tie

The selection process of the top ties for your application can vary depending on the type of application and the intended use. Seeking guidance from manufacturers and experienced professionals in the industry might ease the selection troubles. Below are some various factors to consider during the selection process.

- Understand the design specifications of a transmission which should be compatible to top tie system.

- Evaluate the mechanical loads that the system needs to withstand to help in selection of components. They should handle those loads without compromising on the structural integrity of the line.

- Consider the environmental conditions in the area of installation. consider factors like wind speed, seismic activity and temperature. This is to ensure the chosen system helps to withstand these conditions.

- Assess the reliability and maintenance of the top tie system. Consider factors like ease of inspection, accessibility for maintenance and availability of spare parts.

- Familiarize yourself with the relevant industry standards of the area. This is to ensure the top tie system meets or exceeds them to ensure safety and compliance.

- Consult with reputable manufactures for guidance on the appropriate system for your application. They also offer insights based on their expertise and expert knowledge.

- Evaluate the cost-effectiveness of the system considering both initial investment and long-term maintenance requirements. This ensures a balance between the cost and the desired performance, reliability and lifespan of the system.

Frequently asked questions

Top ties are devices used to add the stability and support to the conductors across long distances. They also limit the lateral movement and singing of the conductors during high winds or severe weather conditions.

There are various types of the top ties used on the installation of transmission lines. They in suspension type top tie, bundle type top tie, vibration dampers top tie, strain dampers top tie and tension type top tie.

The top ties offer several advantages that make them a popular option in the industry. These include mitigation of environmental impacts, compliance with regulatory requirements, increased reliability, improved line performance and enhanced conductor stability.

They also have limitations to consider when selecting for your instllations. These include increased wind loading, electrical clearance limitations, maintenance requirements, potential for conductor abrasion and environmental considerations.