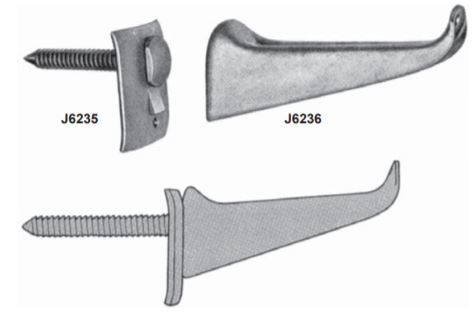

A pole step is a lag screw that has an L-shaped end screwed into a telephone or electric light pole to create a step for climbing. The L-shape end provides a secure grip for the foot and the screw allows for easy removal. This device helps linemen and utility workers during maintenance and repair tasks. A pole step is from materials such as steel, aluminum for durability and longer serviceable life. Pole steps ensure well-being of workers when performing tasks at heights. They mostly find use in utility and telecommunications industries.

Components of a pole step

Pole step components ensure the pole steps provide a safe and reliable means for workers to access utility poles. They help during maintenance, repair and installation tasks. The components also work together to enhance efficiency of utility industries. The following are the main components of a pole step.

- Lag screw – this is the main component that drives into the utility pole to provide a secure attachment point. The screw has a pointed end to facilitate insertion into the pole.

- L-shaped step – the L-shaped step is an essential feature of the pole steps that serves as a platform for the worker to place their foot while climbing. The shape helps to prevent the foot from slipping off the step.

- Threaded shank – this is the part of the lag screw with spiral grooves. I facilitates insertion and secure attachment to the utility pole. It provides a firm grip in the wood to enhance stability.

- Collar – some pole steps have a collar just below the L-shaped step that acts as a stopper for the screw.

Types of pole step

There are several types of pole steps each designed to cater to specific needs and preferences of workers. They also provide different levels of safety and convenience. The types of pole steps vary depending on the local regulations and industry standards. Additionally, you should select the pole steps that best suits your application depending on its needs. The following are the common types of pole steps.

- Standard L-shaped pole step – this is the most used type of pole steps that consists of a lag screw with an L-shaped end. This provides a secure foothold for climbing suitable for various utility pole types.

- Folding pole step – this offers the ease of retractability which features a hinged design that allows the L-shaped step to fold up when not in use.

- Safety-slot pole step – this type has an extended L-shaped step that allow workers to adjust their foot position more easily. This improves comfort and stability while climbing.

- Screw anchor pole step – screw anchor pole steps have a different installation mechanism that utilize a helix-shaped screw-like anchor that drives into the pole.

- Offset pole step – these steps have an off-center L-shaped end which provides a more ergonomic foot position for the worker during climbing.

Applications of pole steps

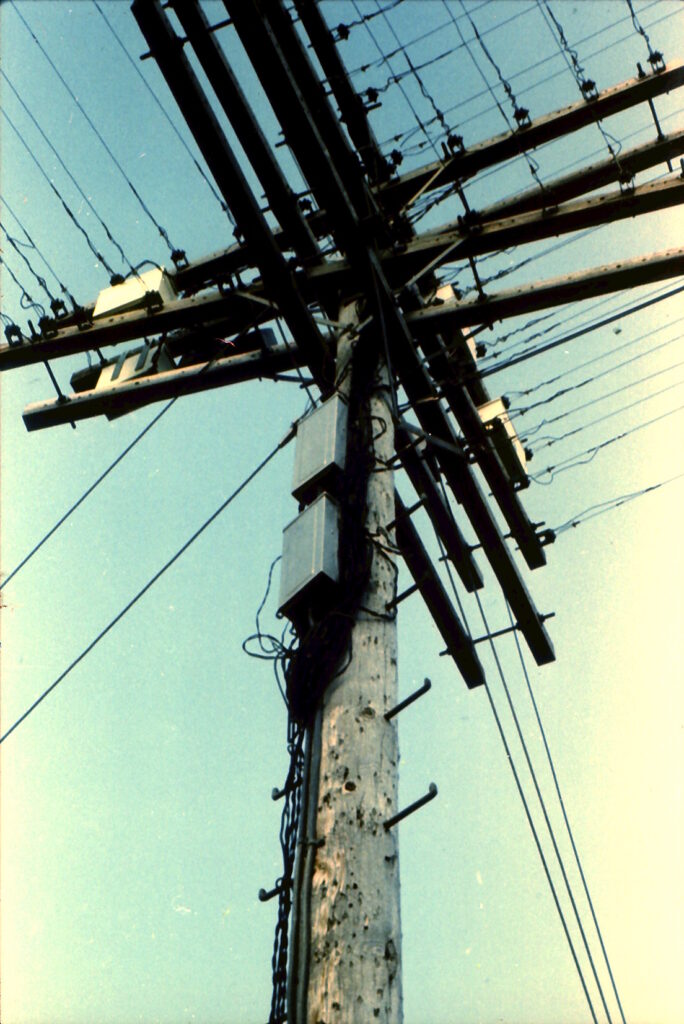

Pole steps find use in various applications like telecommunications and electric utility industries to assist workers in climbing and descending. This climbing and working in heights involves risks and requires proper training and safety equipment. Also, it is advisable to consult with professionals for guidance on the best pole steps that best suits your project. The following are the common application areas of the pole steps.

- Military and outdoor activities – pole steps work in certain military operations to assist in ascending or descending utility poles.

- Lineman training – pole steps work in training programs for utility workers and linemen to practice climbing techniques and safety procedures.

- Sign and banner installation – pole steps help workers hang banners or signs on utility poles along roadsides.

- Street lighting maintenance – pole steps help workers to access streetlight poles for bulb replacement, repairs and maintenance. This ensures proper street lighting in communities and roadways.

- Electric utility maintenance – utility workers use pole steps to climb poles for maintenance and repair tasks on electrical power distribution and transmission systems.

- Power line inspection – utility workers use pole steps to access power lines and identify any issues that may require immediate attention.

- Surveillance and security – security personnel use pole steps to install, maintain or adjust security cameras and other surveillance equipment on utility poles.

- Telecommunication infrastructure installation – workers utilize pole steps to access utility poles and install or maintain communication lines.

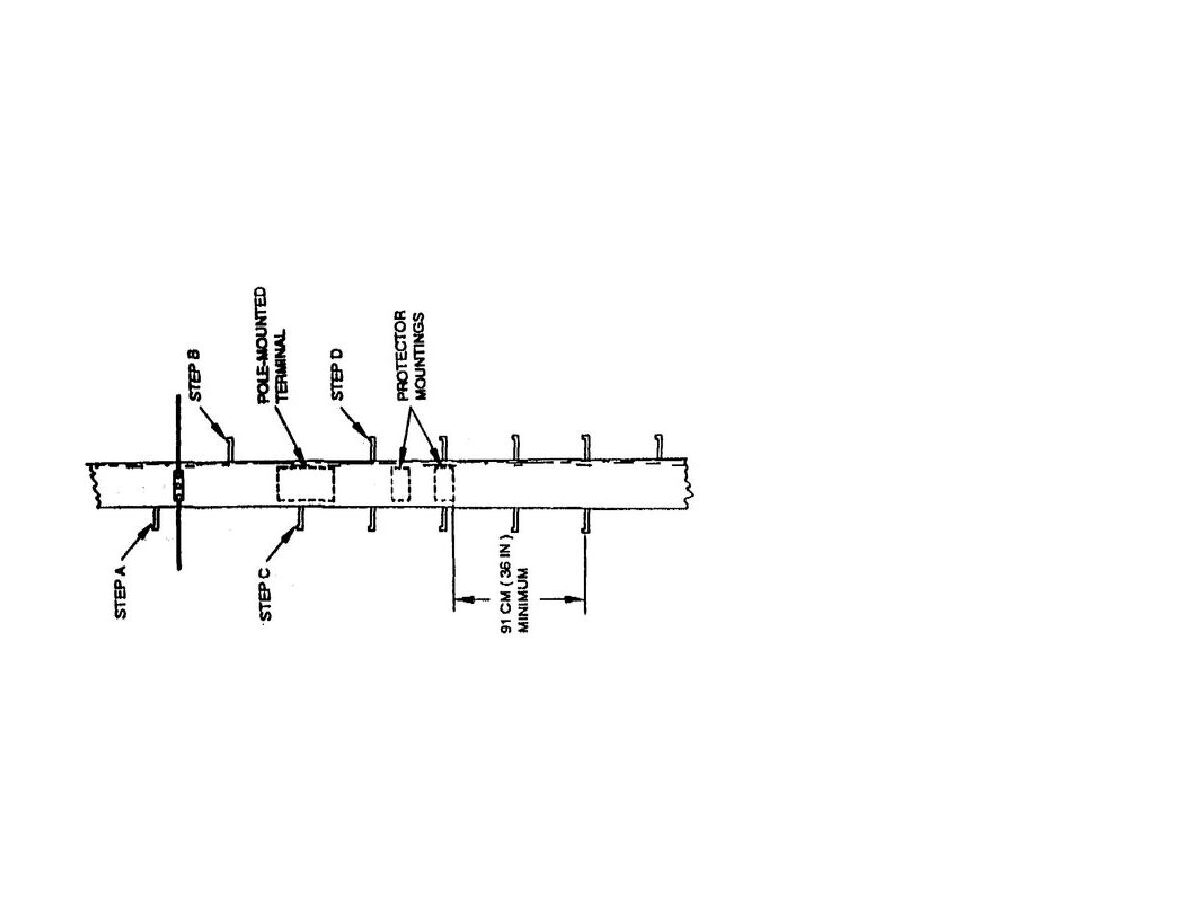

Installation guide for pole steps

The installation process of the pole steps involves securely attaching the pole steps to a utility pole to create a stable foothold for workers to climb. Ensure you follow all the safety protocols and procedures when climbing utility poles. Additionally, it is advisable to seek guidance from qualified personnel to receive proper training before installing a pole step. The following is a basic procedure for installing the pole steps.

- Ensure you have the correct size and type of pole step for the utility pole you are working on. Check for any damages or defects of the pole step before installation.

- Select the suitable location on the utility pole for installing the pole step which should be at a height comfortable for climbing.

- Attach the pole step aligning the lag screw with the available holes or at the desired position on the pole.

- Drive the lag screw into the utility pole and apply firm and consistent pressure to insert the screw fully.

- Continue driving the lag screw until the pole is tightly and securely connected to the utility pole.

- Test the stability of the pole step by applying pressure to it and verifying that it does not move.

- Conduct a final safety check to ensure it is securely attached and ready for use.

Choosing the best pole step

Choosing the right pole steps is crucial for optimizing worker efficiency and safety during line installations and repairs. The selection process also depends on several factors. These factors include specific application, type of utility pole, safety considerations and the preference of workers. The factors to consider are as discussed below.

- Consider the different types of pole steps available and their advantages and disadvantages.

- Select pole steps that offer features that provide comfort and safety during climbing.

- Consider the ease of installation and removal of the pole step and choose one that suits your installation preference.

- Ensure the selected pole step meets all the relevant safety regulations and industry standards.

- Determine the specific tasks you will be performing while using the pole steps.

- Select a pole step that is familiar to the workers to enhance their safety and efficiency.

- Determine the material of the utility pole and ensure the material and design are compatible with the pole material.

- Check the load capacity rating of the pole steps to ensure it can safely support the weight of the worker during climbing.

- Select pole steps made of durable materials to withstand outdoor conditions and resist corrosion.

Frequently asked questions

A pole step is a device used to climb onto utility poles safely during maintenance and repair tasks of pole steps. It has an L-shaped to provide a secure foothold for climbing.

The components of the pole steps work together to provide safety and efficiency during utility pole tasks. They include lag screw, L-shaped step, threaded shank and collar.

Pole steps offer several benefits for workers in utility industries for safety and efficiency when climbing. The benefits include emergency response, cost effective, compliance with regulations, portability and removability, versatility, accessibility and enhanced safety.

There are various limitations of the pole steps to take into account during selection of the pole steps. The limitations include limited applications, physical requirements, safety hazards, installation complexity, weight limitations, restricted access and non-compatibility with certain poles. Consider these factors before selecting pole steps for your project.