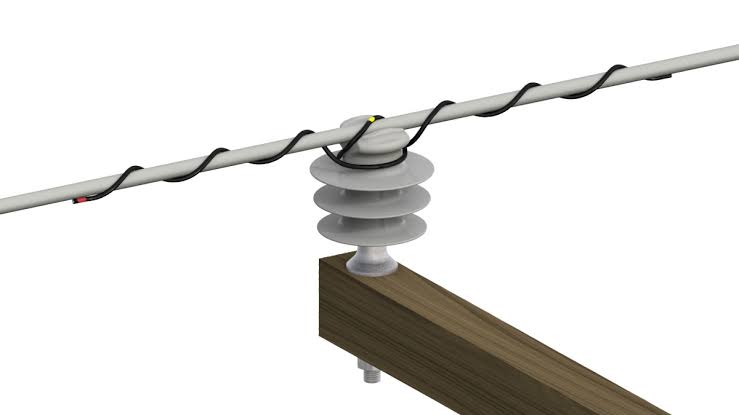

A top tie is a type of conductor tie used to secure the electrical conductors to the insulator on crossarms. Its main purpose is to hold the conductor in place and ensure proper electrical contact. It is also able to do this while allowing for some movement due to thermal expansion, wind and other factors. A top tie has the design to wrap around the conductor and the insulator. There are designs shaped to fit the specific conductor sizes and insulator types. The top ties also include insulation to prevent electrical arcing. Top ties are from materials such as aluminum, copper or a combination of both. These materials provide conductivity and compatibility with the conductor material.

Properties of a top tie

Top ties have several properties to ensure their continued performance under various conditions. Each property ensures the top tie provides a secure and reliable connection for conductors. The following are the common properties of the top tie.

- Electrical conductivity – top ties are from materials like aluminum and copper. These materials have high electrical conductivity. This ensures minimal electrical resistance and efficient electricity transmission.

- Mechanical strength – the top ties must be strong enough to withstand the mechanical stresses. The tensile strength and durability allows them to withstand wind, ice loading and thermal expansion and contraction.

- Corrosion resistance – the ties should be from corrosion-resistant materials to ensure longevity and reliability.

- Flexibility and elasticity – top ties need to allow for some movement due to thermal expansion, vibrations and other forces. This is to prevent damage to the conductor and insulator.

- Compatibility with conductors and insulators – top ties should be compatible with the specific type of conductors and insulators they work with. This is to ensure a secure fit and proper electrical contact.

- Ease of installation – the ties should be easy to install with standard tools and techniques. This is to ensure a secure and stable connection without requiring excessive time or effort.

- Thermal stability – the materials used in top ties must be able to withstand temperature variations without degradation.

- Insulating properties – some of the ties comprise of insulating materials or coatings. These properties help to prevent electrical arcing and enhance system reliability.

Community forums and interactions for a top tie

Engaging in community forums and online platforms allow professionals and engineers to share knowledge and discuss best practices. Participating in these forums can help you stay updated on industry trends, improve skills and connect with other professionals in the field. The following are the platforms and types of interactions for top ties.

- Industry-specific forums – these include IEEE, Electric Power Research Institute and Electrical Engineering Stack Exchange. These forums provide research reports, technical forums, Q&A and new technologies discussions.

- Social media and online communities – these include professional groups focused on power transmission and distribution. Platforms include LinkedIn, Facebook and Reddit.

- Manufacturer and supplier forums – these are forums hosted by manufacturers and suppliers. They provide technical suppler, product-specific discussions, product usage and installation techniques.

- Professional associations and conferences – these include American Society of Civil Engineers(ASCE), International Council on Large Electrical Systems (CIGRE), trade shows and conferences.

- Online courses and webinars – there are online courses on power systems and electrical engineering. This is including Coursera, edX, and webinars hosted by experts.

- Internal communication platforms – many companies have their own intranet sites and forums. Professionals and employees are able to discuss technical issues.

Selecting the best top tie

There are several designs and types of top ties to select from for overhead transmission lines. The selection process involves considering factors that ensure performance, longevity and safety. Additionally, it is important to seek professional or expert help to select the right ties for your specific needs. The following are the factors to consider when selecting top ties.

- Conductor type and size – ensure the top tie is compatible with the conductor material and must fit the specific diameter of the conductor.

- Insulator type and size – ensure the top tie is compatible with the specific type of insulator used. It should wrap around the conductor and insulator.

- Environmental conditions – it is important to select materials with high corrosion resistance. This is ideal for use in areas with high humidity, salinity or pollution. The tie should also withstand the local temperature variations without degradation.

- Mechanical strength – the top tie should have enough tensile strength to support the mechanical loads. It should be flexible enough to accommodate movements caused by thermal expansion, wind and other dynamic forces.

- Electrical properties – ensure the top tie provides enough electrical conductivity to maintain the integrity of the transmission line. Some of the ties may need extra insulation to prevent arcing and enhance safety.

- Installation ease – the top tie should be easy to install with standard tools and techniques.

- Cost and availability – consider the cost of the top tie and ensure it is within the budget. It should also be readily available and easily sources within the required time.

- Manufacturer and quality assurance – choose top ties from reputable manufacturers. They should be reputable for producing high quality products. Check for warranties, technical support and customer service options.

Installation procedure for top ties

The installation process for a top tie involves several steps that ensure a secure and stable connection. The manufacturers also provide product specifications that may offer guidelines for installation. Tools and materials needed include top tie, insulator, conductor, pliers, torque wrench and safety gear. The following is a detailed guide on the installation process for top ties in overhead transmission lines.

- Component inspection – check the top tie, conductor and insulator for any damage or defects. Ensure the top tie is compatible with the conductor size and insulator type.

- Conductor positioning – place the conductor in the insulator groove and ensure it is properly seated and aligned.

- Top tie attachment – for preformed top ties, align the center mark of the tie with the insulator’s center. Wrap the preformed tie around the conductor and insulator and ensure the ends are well secured. For conventional top ties, position the top tie over the conductor and insulator. Wrap one end of the tie around the conductor and insulator. Use lineman’s pliers to twist the tie securely and repeat the wrapping process for other end of the top tie.

- Securing the top tie – ensure both ends of the top tie are securely wrapped and twisted. Check for any loose ends or slack that could cause movement or damage.

- Checking installation – inspect the installed top tie for proper alignment and securement. Ensure there are no sharp edges or protrusions that could damage the conductor. Verify that the conductor is firmly held in place and cannot move.

- Final adjustments – make any necessary adjustments to ensure the top tie is tight and secure. Double-check all connections and ensure everything is properly aligned.

- Documentation – record the installation details including the type of top tie used and the date of installation.

Maintenance and inspection of top ties

Consistent maintenance and inspection of top ties ensures their reliability and performance in overhead transmission lines. It also helps to identify and address potential issues before they lead to failures. Additionally, it is advisable to perform professional inspection and maintenance annually or semi-annually. The following is a basic guide on the maintenance and inspection of the top ties.

- Ensure all personnel involved are properly trained and knowledgeable about the procedures and equipment. Follow all safety protocols and use suitable protective equipment.

- Inspect the installation for signs of rust, corrosion, wear, loose connections, electrical arcing or material degradation. Ensure the conductor is properly seated in the insulator and the top tie is securely wrapped.

- Conduct thermal imaging to detect hot spots that show poor connections or increased resistance. Investigate and address any abnormal temperature readings.

- Perform resistance testing to ensure proper electrical contact on the system. Measure and record the electrical properties of the connections.

- Conduct mechanical load tests to ensure the top ties can withstand the required mechanical stresses. Inspect for any signs of mechanical fatigue or failure.

- Use suitable cleaning solutions and tools to remove dirt, debris and contaminants from the top ties and insulators. Avoid using abrasive materials that could damage the top tie or conductor.

- Use lineman’s pliers or other suitable tools to tighten any loose top ties. Ensure all connections are secure and there is minimal movement on the transmission line.

- Maintain detailed records of all inspections, maintenance activities and replacements. Include details such as dates, observations, actions taken and personnel involved in the activities.

Frequently asked questions

A top tie helps to secure the electrical conductor to the insulator on the crossarm of a utility pole. It ensures proper electrical contact and stability while allowing for movement due to thermal expansion, wind or other environmental factors.

Consider compatibility with conductor type and size, insulator type, environmental conditions, mechanical strength, electrical properties, cost, and ease of installation.

Common issues include corrosion, wear and tear, loose connections, and electrical arcing. Addressing these issues involves tightening loose ties, cleaning affected areas and ensuring proper installation and materials used.