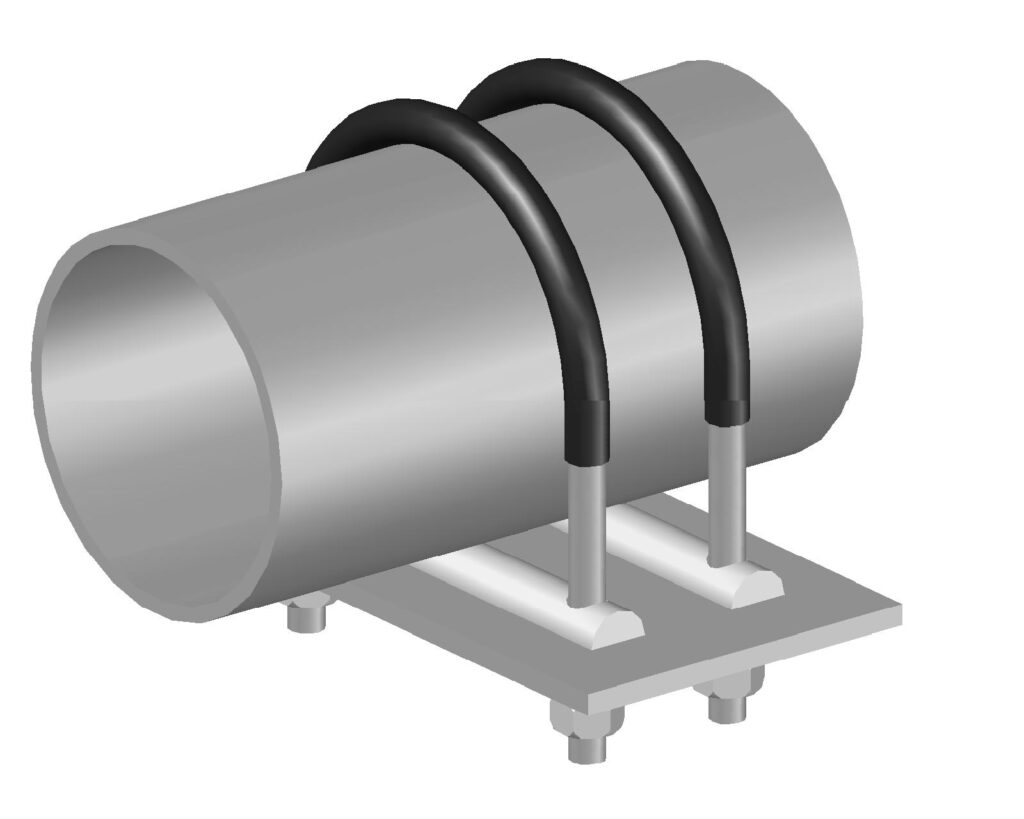

A U-bolt is a type of fastener used to secure and attach various components in overhead transmission lines. It consists of a threaded rod with a U-shape bend at one end and two threaded ends with nuts. The threaded ends of the U-bolt pass through the mounting holes of the components to secure. The nuts tighten onto the threads to hold the U-bolt in place. The design allows for a secure and adjustable connection which makes it easy to install and maintain. It is from materials such as carbon steel, stainless steel or other alloys. It may also include coatings and corrosion resistant finishes for longer service life. Examples include round U-bolt, square U-bolt, semi-round U-bolt and rounded bend U-bolt. They find use in applications such as plumbing, construction building, electrical installation and telecommunication towers.

Key features of U-bolt

U-bolts have several features that make them suitable for a wide range of applications. They also make them suitable for different industries and applications. The following are the key features of U-bolts.

- U-shaped design – this design allows them to clamp around the item they are securing. This helps to provide a secure and stable attachment.

- Material composition – they are from materials such as steel, stainless steel or other alloys. These helps them to resist various weather conditions.

- Types and shapes – they are available in shapes such as round, square, semi-round and custom shapes. The choice of the bolt depends on the specific application and the requirements of the components to secure.

- High-temperature resistance – the bolts have designs to withstand high temperatures. This makes them suitable for outdoor applications. This is mainly through the use of heat-resistant materials or coatings.

- Strength and load capacity – they have various levels of strength to accommodate different load capacities.

- Ease of installation – the U-bolts have various designs for easy installation.

- Threaded ends – the threaded ends allow for easy installation and adjustment for proper security.

- Corrosion resistance – the bolts have finishes that resist rust and corrosion in various environmental conditions.

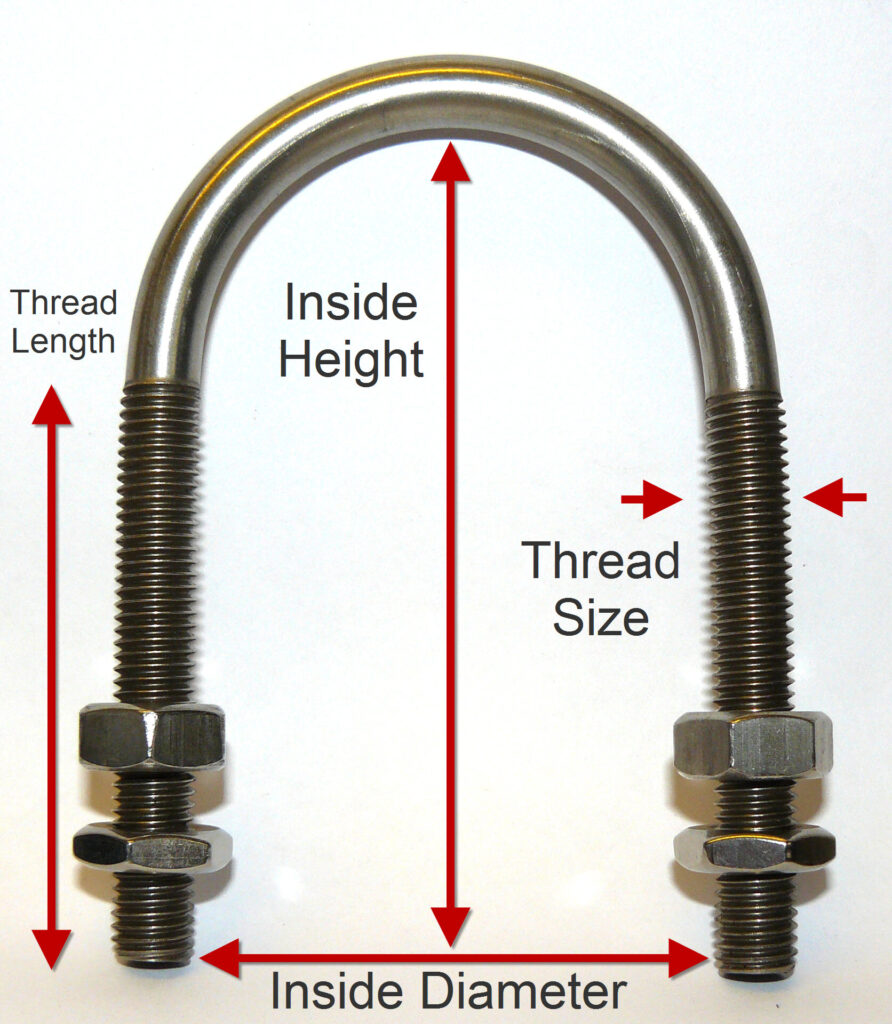

- Length and diameter – they are also available in different lengths and diameters. This is to accommodate various sizes of pipes, cables and other components.

Selection and installation of U-bolt

The selection process ensures the chosen bolt is suitable for the specific application. It also helps to ensure it meets the required performance criteria. It involves considering factors such as application requirements, material, coating, type of U-bolt, size and dimension, strength and load capacity. The installation involves securing them around a pipe, rod or other components. The following is a basic installation process of the U-bolt.

- Preparation – gather all the necessary tools required for the installation. This includes U-bolts, nuts and washers, wrench and safety equipment.

- Positioning – place the bolt around the pipe and ensure the legs of the U-bolt are evenly spaced.

- Add washers – place the washers on the threaded ends off the U-bolt to provide a flat surface for the nuts to tighten against.

- Thread the nuts – thread the nuts onto the threaded ends to secure the U-bolt in place.

- Align the U-bolts – ensure that the U-bolt is properly aligned and centered around the pipe to maintain balance and stability.

- Nut tightening – use a wrench to tighten the nuts on both ends of the U-bolt to ensure uniform pressure.

- Torque wrench – use a wrench to achieve the recommended torque level.

- Check alignment – check the alignment and centering of the U-bolt to ensure proper performance.

- Final inspection – visually inspect the U-bolt and its components to ensure there is no gaps and the U-bolts is securely fastened.

- Documentation – keep the installation details including the torque levels for future reference.

Maintenance and inspection of U-bolt

Proper maintenance and inspection helps to ensure their continued effectiveness and safety. It also helps to ensure the longevity and reliability of U-bolts in various applications. It also helps to identify and address issues that could lead to potential failures. Additionally, it is important to perform professional inspections and maintenance to enhance performance. The following is a basic guide on the maintenance and inspection in South America.

- Check the alignment of the bolt around the pipe to ensure it is properly secured as it can lead to stress.

- Regularly inspect U-bolts for signs of wear, corrosion or damage to look for deformation cracks or changes.

- Clean the U-bolts to remove dirt, debris or corrosive substances as a mild detergent and a brush to clean the surface.

- Apply corrosion resistant coatings such as galvanizing or anti-corrosion sprays. This is to protect U-bolts in outdoor environments.

- Check the tightness of the nuts on the U-bolts to the specified torque values.

- Inspect the threads on the U-bolts for any signs of wear, stripping or damage. the damaged threads may compromise their ability to securely fasten components.

- Perform visual inspections of the entire U-bolt including the bend and threaded ends. This includes checking for cracks, bends or deformations.

- Examine the U-bolt for signs of corrosion in areas with exposure to moisture or harsh chemicals to prevent deterioration.

- Verify the U-bolt’s load bearing capacity is still suitable for the application. Consider upgrading to a U-bolt with a higher load rating.

- Keep records of the inspection, maintenance activities to help keep track for future and maintenance decisions.

Comparative analysis of U-bolts in South America

A comparative analysis includes examining various aspects of the bolt such as types, materials and applications. It also helps to ensure proper selection for various application needs in the industry. Also, it is important to consult with industry professionals to ensure the U-bolt holds the expected loads. The following are the factors to include in the analysis for U-bolts in South America.

- Type of U-bolts – assess the usage and preference of different types of U-bolts in south America. They include round, square, semi-round and custom shapes.

- Application – evaluate the wide range of applications of U-bolts. This includes construction, telecommunications, automotive and marine.

- Environmental considerations – evaluate how the environmental conditions affect the usage of the U-bolt in South America. These conditions include tropical climates, coastal areas or high humidity.

- Local manufacturing and suppliers – assess the availability of manufacturers and suppliers of U-bolts. Also, check the preference for locally produced bolts and reliance on imports.

- Challenges and innovation – check any innovations developed to address the various challenges. This helps to promote efficiency and safety.

- Material and coating – consider the materials used to manufacture the U-bolts such as carbon steel, stainless steel or alloys. This also includes considering the various environmental conditions in South America.

- Economic factors – this is including the cost effectiveness, availability of materials and the impact of economic conditions on procurement decisions.

Certifications and standards in South America

Most of the certifications and standards in south America helps to ensure quality, safety and reliability of the bolts. They also help to ensure the bolts meet specific criteria for material properties, dimensions and performance. The following are the certifications and standards in South America.

- ASTM standards – these are for various materials and products especially for testing and materials for u bolts.

- ASME standards – this is standards for a variety of mechanical components including requirements for hex bolts, screws and studs.

- ANSI standards – this covers a wide range of products specific to the fasteners.

- SAE standards – these are standards mainly used in the automotive industry specifically for the mechanical and material requirements for threaded fasteners.

- ISO certifications – this provides international standards for a wide range of products especially for mechanical and physical properties for bolts.

Regional market for U-bolts in South America

There are various factors that influence the regional market for U-bolts in South America. They also influence the demand and availability of the products in the market. Additionally, it is important to understand the various market trends and dynamics to stay ahead in the market. The following are the factors that shape the regional market for U bolts in South America.

- Automotive industry – u bolts find use in the automotive industry especially in the manufacturing and maintenance of vehicles. They help to ensure the stability and safety of vehicles.

- Telecommunications and energy – increased demand for communication networks and energy distribution also increases the demand for U-bolts.

- Trade dynamics – the availability of locally manufactured U-bolts also influence the market dynamics in the region.

- Economic factors – this is including GDP growth, inflation rates and investment climate which affect the demand for construction and infrastructure projects.

- Infrastructure development – the growth of industry such as construction of roads, bridges and utility projects also influence the stability of structures.

Frequently asked questions

U-bolt is a U-shaped piece of metal with threaded ends used to secure pipes, tubes and other round objects. They mostly help in securing, rigging, guiding and supporting a wide range of components and structures.

U-bolts are from materials that offer different properties and performance characteristics. These materials include carbon steel, stainless steel, galvanized steel or alloys. Consider their strength, corrosion resistance, weight and cost when selecting U-bolts.