A cable suspension clamp is a hardware component used on power transmission lines to suspend and support the conductors. It securely holds the cables in place to ensure a proper tension and clearance. Additionally, the cable suspension clamps prevents the conductors from sagging excessively under the weight and tension of the transmission line. This helps to ensure safe and efficient operation of the power transmission system. Cable suspension clamps are from materials such as galvanized steel or aluminum alloy. These materials helps to withstand the mechanical stress and eternal forces.

Components of the cable clamp

Components of the cable suspension clamp vary depending on the manufacturer, application and specific requirements of the power transmission system. The available components work together to secure and support the conductor. The following are the main components of the cable suspension clamp.

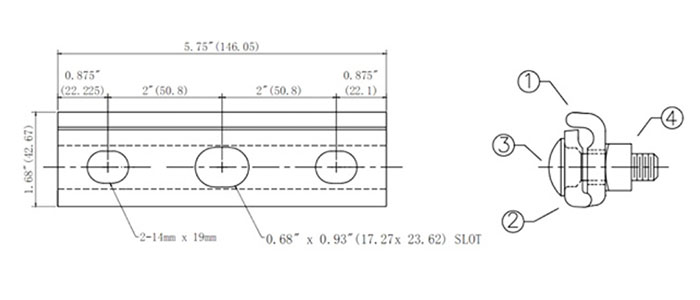

- Body – this is the main component of the cable suspension clamp made of durable materials such as steel or aluminum alloy.

- Loop – this is a component attached to the body of the clamp that serves as the attachment point for the conductor.

- Bolt – bolts and fasteners secure the conductor within the clevis to hold firmly in place.

- Locking mechanism – cable suspension clamps use a locking mechanism such as locknut or locking plate to prevent the bolts from loosening.

- Protective coating – the protective finish enhances the resistance to corrosion and other environmental factors.

Types of cable suspension clamp

There are various types of cable suspension clamps used on the overhead transmission lines. They help to select depending on the requirements of your application. The available types depend on factors such as conductor size, line configuration and the desired level of tension. The following are the common types of the cable suspension clamp.

Bolt type suspension clamp – this type of suspension clamp uses bolts to secure the conductor in place. They consists of a body with a clevis or loop for conductor attachment and multiple bolts for tightening and securing the conductor.

U-bolt clamps – these are the most common types of cable suspension clamps made from stainless steel and have a U-shape body.

Preformed suspension clamp – these clamps have a design that provides uniform distribution of forces along the conductor.

Eyebolt clamps – eyebolt clamp have an eyebolt instead of a U-shaped body to secure the cable to the support structure.

Wedge type suspension clamp – this is a type of suspension clamp that employs a wedge-shaped component to grip the conductor. It mainly consists of a body with a wedge-shaped groove.

Ratcheting cable clamp – this is a type of cable suspension clamp that use a ratcheting mechanism to tighten the cable. They are mostly used for temporary applications.

Applications of cable suspension

The areas of applications for the cable suspension clamp vary based on the type of power infrastructure, regional requirements and project specifications. The right cable should ensure stability, performance and durability of the power systems. Cable suspension clamps work in telephone and communication lines, cable plates, cable ladders among other applications. Below is a detailed description of the various application areas of the cable suspension clamps.

- Overhead transmission lines – cable transmission lines work in these areas to support and suspend conductors to ensure proper tensioning of the conductors. This helps maintain clearance requirements and provide secure attachment points on transmission lines or poles.

- Substations – the cables secure conductors to the substation structures to contribute to the stability and reliability of the transmission lines.

- Pole attachments – the cable suspension clamps attach conductors to transmission towers and utility poles. This provides a secure connection point and support the weight of the conductors.

- Fiber optic cable suspension – they also suspend and support fiber optic cables in communication networks. This provides a secure attachment point for the fiber optic cables to ensure reliable data transmission.

- Cable bundling applications – multiple cables hustle together using the cable suspension clamps. They help maintain the desired spacing, alignment and stability of the bundled cables.

- Distribution networks – cable suspension clamps maintain the desired tension, prevent excessive sagging and ensure efficient power distribution to consumers.

Installation guide for the cable suspension

Installation process of the cable suspension clamp vary depending on the specific design and manufacturer’s instructions. The process should also adhere to the relevant industry standards, local codes and project requirements. Additionally, it is advisable to consult with a qualified professional or seek guidance from the manufacturer. The following is a basic guide on how to install the cable suspension clamp.

- Prepare the work area and ensure it is safe and clear of any obstructions. You should also follow the industries safety precautions.

- Identify the appropriate location for installing the cable suspension clamp. Consider factors such as conductor size, clearance requirements and attachment points on transmission poles.

- Inspect the cable suspension clamp and its components for any damage and ensure all necessary components are available.

- Position the clamp at the desire location on the conductor and ensure the clevis aligns with direction of the transmission line.

- Attach the cable suspension around the conductor and ensure a tight fit following the manufacturer’s guidelines.

- Tighten the bolts and fasteners using an appropriate tool to achieve the desired torque level.

- Install insulation if required and ensure the insulating material is properly positioned. This helps provide suitable electrical insulation between the conductor and the clamp.

- Visually inspect the installation to ensure that it is properly tightened and there is enough clearance between the conductor and other components.

Selecting the best cable suspension clamp

Different manufacturers and suppliers in the market produce different types and designs of the cable suspension clamp. This makes the selection process a bit hard depending on the specific requirements of the applications. The selected cable suspension clamp should ensure a secure, reliable and efficient suspension of conductors. The following are the key factors to consider when the selecting cable suspension clamps for your project.

- Study the cost effectiveness and value of the cable suspension clamp by comparing features, performance and durability of the different options available.

- Evaluate the compatibility of the cable suspension clamp with the available hardware on the transmission lines.

- Consider the size and type of conductor to suspend by checking on the conductor’s diameter and configuration.

- Evaluate the material used in the construction of the cable suspension clamp. The material should ensure they are corrosion-resistant, durable and capable of withstanding the external factors.

- Check if any insulation is necessary between the conductor and the clamp.

- Determine the expected load that the cable suspension clamp will support.

- Consider the reputation of the manufacturer who should have a track record of producing high-quality, tested and certified cable suspension clamps.

- Assess the installation process and maintenance requirements associated with the cable suspension clamp.

Frequently Asked questions

This is a hardware component used to suspend and support the conductors and holds the cables or conductors n place. This ensures proper tension and clearance of the overhead components.

Hirth joint cable clamp

Ratcheting cable clamps

Bolt type suspension clamp

Eyebolt clamps

Wedge type suspension clamp

Secure conductor attachment

Even load distribution

Enhanced conductor support

Ease of installation

Corrosion resistance

Cost effective

Installation complexity

Load capacity restrictions

Limited compatibility

Maintenance requirements

Limited adjustability

System expansion