Pole line hardware refers to components used in the installation of utility poles. They are also known as utility pole hardware or power pole hardware. These components ensure the stability, safety and reliability of electrical distribution. Pole line hardware include devices that secure conductors and insulators to utility poles. Pole line hardware is from different materials such as carbon steel, aluminum or galvanized steel. These materials offer rust and corrosion resistance and durability. They work in applications such as transmission lines, construction and cable suspension.

Components of pole line hardware

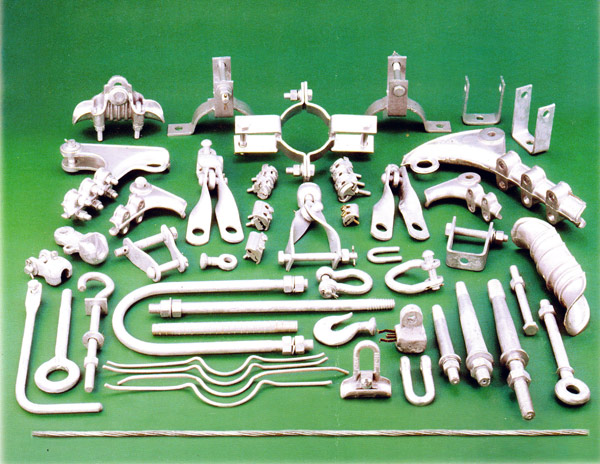

A range of components work together to ensure stability, reliability and safety of electrical distribution systems. The pole line hardware components help in the construction and installation of utility poles. The following are the common components of the pole line hardware.

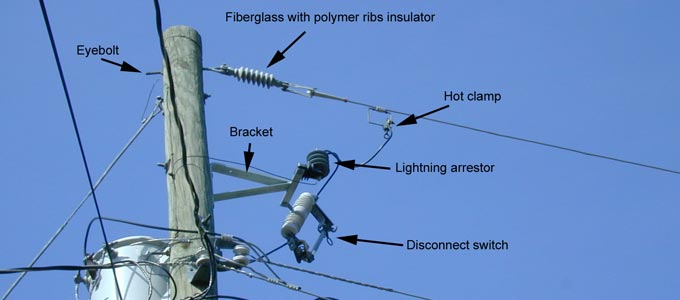

- Insulator pins – these help to secure insulators to utility poles. They provide electrical insulation and supporting the weight of the conductors.

- Guy clamps and anchors – these help to secure the guy wires to the utility poles.

- Wire holders and conduit holders – these components help to manage the placement and organization of wires and conduits on utility poles.

- Suspension clamps – these clamps help to suspend and support electrical cables from utility poles.

- Transformer mounts – these brackets help to secure transformers to utility poles. This helps in distribution purposes to ensure proper installation and stability.

- Crossarm brackets – these brackets help to attach crossarms horizontally to utility poles. They also support insulators and conductors and distribute mechanical loads.

- Tension clamps – tension clamps help to secure the conductors to the poles.

- Dead-end clamps – these clamps help to terminate the conductors at the end of the line.

Types of power fittings

There are various types of pole line hardware used in the construction, installation and maintenance of utility poles. These designs and types ensure the functionality, safety and longevity of utility poles. Each type of pole line hardware has its own specific purpose on the overhead lines. The specific type selected depends on the type of application and voltage levels of the transmission lines. The following are the common types of pole line hardware.

- Guy wire – this is a component used for enhancing the stability of the pole by balancing the overload.

- Guy anchor – the guy anchor connects the guy wire to the ground to balance tall buildings and structures.

- Pole band – this acts as a point for creating secondary racks to the pole. The racks are then used to hold other essential components.

- Secondary rack – this works as a platform for holding insulators and organize multiple secondary wires to the utility pole.

- Steel crossarm – these connect the body cage of transmission tower and power line insulators.

- Streetlight arm – this component extends from the pole to provide a platform to attach the lighting fixtures.

- Secondary clevis – this includes a punched steel and a clevis pin used to connect with the pool insulator to the pole.

- Guy grip – this is also known as a guy grip used to connect guy wires and grounding anchors.

Applications of power line hardware

Pole line hardware find use in various applications in the construction, operation and maintenance of utility poles. They ensure the stability, reliability and safety of electrical distribution and transmission systems. Additionally, it is advisable to consult with professionals on guidance on the best accessories to use. The following are the common application areas of pole line hardware.

- Overhead power lines – pole line fittings helps to connect, support and protect overhead power lines.

- Telephone lines – the components help to connect and protect the telephone lines.

- Mechanical stability – crossarm brackets and guy clamps provide mechanical stability to utility poles.

- Pole stability – guy clamps and anchors help to secure guy wires which provide extra stability to utility poles.

- Electrical safety – grounding hardware establishes effective grounding systems. They dissipate electrical currents safely into the ground.

- Cable suspension – the clamps support and suspend electrical cables from utility poles. This is to prevent sagging and ensure proper cable alignment.

- Aesthetic – properly installed and organized pole line hardware contributes to a clean and organized visual appearance of power line installations.

- Maintenance – inspection tags and markers provide essential information for maintenance crews. This helps them identify poles and perform necessary repairs.

Installation of pole line accessories

The installation process is a critical process that involves planning, adherence to safety protocols and proper techniques. This ensures the stability, reliability and safety of utility poles and overhead power lines. Also, refer to manufacturer guidelines and safety standards specific to your project. In Southeast Asia, selecting the suitable installation method helps to ensure effective electrical insulation and reliable power distribution. The following is a basic installation procedure for the pole line hardware.

- Ensure you follow all the safety protocols and procedures. Identify the potential hazards at the installation site.

- Collect all the necessary components such as fasteners, bolts and nuts needed for the installation.

- Inspect the utility poles to ensure they are structurally sound and capable of supporting the extra hardware.

- Inspect all the pole line hardware components to ensure they are free from defects, damage and corrosion.

- Plan and position at the precise locations for installing each piece of hardware on the utility pole.

- Install all the necessary components of pole line hardware following the manufacturers guide.

- Use suitable torque values to tighten fasteners and ensure all hardware components are securely attached to the utility pole.

- Conduct an inspection to verify that all components are properly aligned, securely fastened and installed according to specifications.

- Document the installation process including the types of hardware used, torque values and any deviations from the original plan.

Selecting the best pole line hardware

There are various types, designs and configurations of the pole line hardware to select from in the market. The selected pole line accessories should ensure stability, reliability and safety of utility poles and overhead power lines. Consider components made from corrosion-resistant materials for Southeast Asian countries prone to humidity and coastal environments. The following are the key factors to consider when selecting the pole line accessories.

- Ensure the selected hardware components are compatible with the existing utility pole infrastructure.

- Choose hardware made from materials that offer mechanical strength, durability and resistance to corrosion.

- Verify that the selected hardware components comply with relevant safety standards and regulations.

- Choose hardware from reputable manufacturers with a track record of producing high quality and reliable products.

- Understand the design specifications of the utility poles and overhead lines. These include voltage levels, conductor types and load requirements.

- Determine the expected mechanical loads and tensions that the hardware will need to withstand.

- Consider the environmental conditions of the installation site. These include such as exposure to weather, humidity and corrosive elements.

- Select hardware that is easy to install to save time and reduce labor costs during the installation process.

Frequently asked questions

Pole line hardware includes a range of components and accessories used in the construction, installation and maintenance of utility poles that support overhead power lines. the components ensure stability, safety and reliability of electrical distribution and transmission systems.

Pole line fittings offer various benefits that enhance the stability, reliability, safety and efficiency of overhead power distribution systems. These benefits include safety, corrosion protection, ease of maintenance, efficient cable management, electrical safety, reliable power transmission and enhanced structural integrity.

Pole line fittings have certain limitations and challenges associated with its use in overhead power distribution systems. They include maintenance requirement, installation complexity, weight and load considerations, aesthetic impacts, aging infrastructure, geographic variability, regulatory compliance and limited customization. Consider these factors when selecting pole line hardware for your installation.