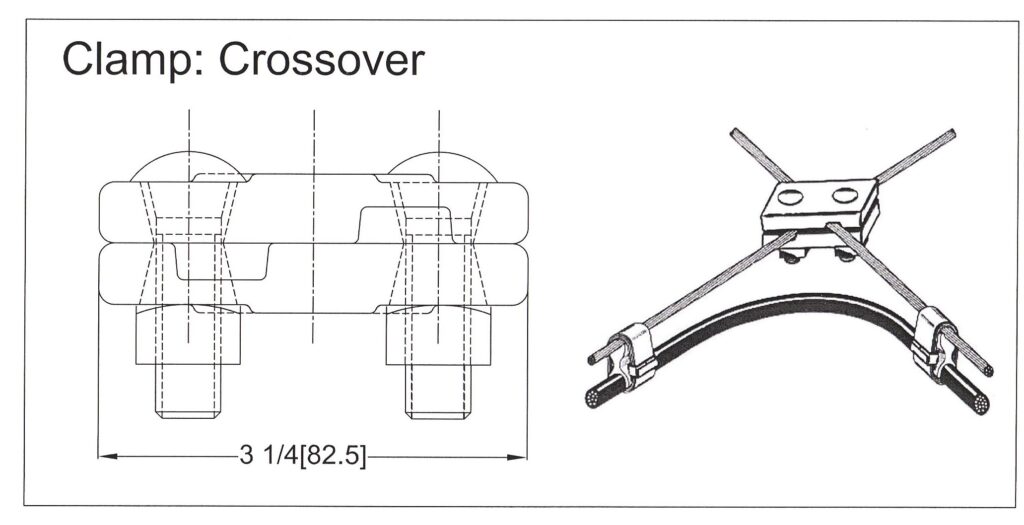

A crossover clamp is a hardware used to provide mechanical support and electrical continuity. This is at points where two conductors cross each other. They securely hold the tow conductors in lace while maintaining the required separation distance. Crossover clamps provide electrical continuity between the crossed conductors. They are from materials such as stainless steel, aluminum or other durable alloys. These materials can withstand environmental conditions to ensure long-term reliability of the transmission line. The regular monsoon rains and high humidity levels in Southeast Asia, highlight the importance of corrosion-resistant materials used in crossover clamps. This enables them to withstand the challenging weather conditions. They also contribute to the durability of infrastructure. Common types of the clamps include straight crossover clamp, clamp and spacer crossover clamp. They find use in various applications such as transmission and distribution, telecommunication and renewable energy.

Key features of crossover clamp

The design and features of crossover clamps aim to provide secure mechanical support and proper conductor separation. They also provide electrical continuity and safety of transmission systems. This leads to the efficient and reliable operation of overhead transmission lines. These features include:

- Material – the clamps are from high-strength materials that can withstand the environmental conditions.

- Size and configuration – the design allows them to accommodate the specific size and configuration of the conductors intended to secure.

- Adjustability – some of the clamp’s design allows for precise positioning of the conductor. This ensures the correct separation distance. This helps to maintain electrical safety and prevent arcing between the conductors.

- Mechanical strength – the clamps provide strong and reliable mechanical support to the conductors. This helps them withstand the mechanical stresses imposed by the tension of the transmission lines.

- Corrosion resistance – for the tropical and humid climate in Southeast Asia, crossover clamps have coatings. These coatings help resist corrosion to maintain their functionality and structural integrity.

- Electrical continuity – the clamps design ensures electrical continuity between the crossed conductors. This is to maintain a consistent electrical path for the current.

Selection and installation of crossover clamp for tropical areas of Southeast Asia

Selecting the right crossover clamp for a specific application in Southeast Asia requires consideration of several factors. Proper consideration ensures safety, efficiency and reliability of your transmission line system. The right selection of crossover clamps helps in regions such as mountainous areas, dense forests and coastal areas. The factors include the conductor type and size, voltage level, material, insulation requirements and mechanical load. Installing crossover clamps on such areas requires careful consideration of the terrain, climate and specific installation practices. Here is a step-by-step process that ensures longevity and efficiency of the crossover clamps.

- Conduct a site survey to assess the specific conditions of the installation area. This include weather patterns, terrain, existing infrastructure and accessibility.

- Make sure to follow all the safety measures which includes proper protective gear, safety training and adherence to local safety regulations.

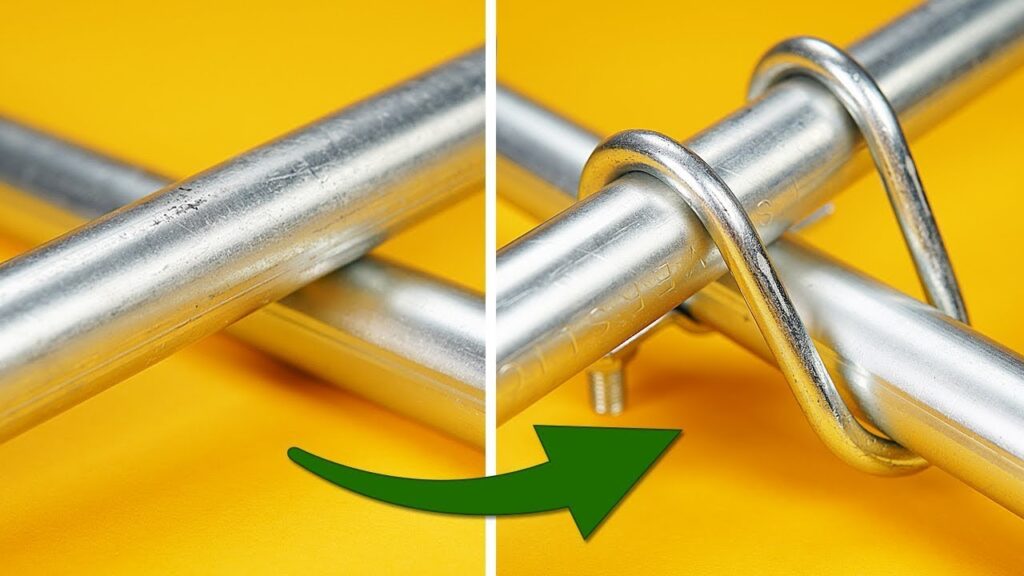

- Prepare the crossover clamps and tools for the installation. Ensure they are in good condition and compatible with the conductors.

- Clean the surfaces of the conductors and ensure they are free from dirt, grease and corrosion to establish a solid connection.

- Determine the suitable spacing between the conductors as specified by the manufacturer.

- Ensure the insulating components position correctly to prevent electrical contact between the conductors.

- Ensure the clamps are securely tightened without over-tightening which could damage the conductors.

- Consider the mechanical load the transmission line will experience due to tension and wind.

- Ensure the crossover clamps are adequately weatherproofed. This is for the humid and variable climate of Southeast Asia.

- Conduct a quality check to ensure that the crossover clamps install properly, align correctly and securely attached to the conductors.

- Keep a record of the installation process including photographs, measurements and any adjustments made.

Maintenance and inspection of crossover clamps

Maintaining and inspecting crossover clamps helps in the challenging climate conditions in the countries. It helps to ensure the longevity, reliability and safety of crossover clamps in transmission line installations. The following is a guide on how to effectively maintain and inspect crossover clamps.

- Establish a regular inspection schedule for crossover clamps especially for humid and varying climate conditions.

- Conduct visual inspections to identify signs of corrosion, wear or damage of the crossover clamps. Look for loose bolts, cracks or changes in alignment.

- Focus on anti-corrosion measures and apply corrosion-resistant coatings or materials. They help to protect the crossover clamps from the effects of humidity and salt.

- Clean the crossover clamp to remove dirt, debris and any buildup that could speed up corrosion.

- Ensure the crossover clamp maintains the proper spacing and alignment between the conductors. This could lead to electrical contact or mechanical stress on the clamps.

- Regularly assess the mechanical load of the transmission lines and check for any signs of deformation or stress on the crossover clamps.

- Evaluate the environmental factors such as heavy rains, typhoons and high temperatures on the crossover clamps.

- Check the tightness of the bolts and fasteners on crossover clamps to increase the effectiveness and safety.

Comparative analysis of crossover clamp in the Southeast Asian market

A comparative analysis involves considering several factors to ensure the best selection of the crossover clamp. This helps to create a scoring system to rank the crossover clamp options based on their suitability for the Southeast Asian market. The specific proprieties and requirements of your project will influence the weighing of each factor. These factors include:

- Brand manufacturer – identify the manufacturers and brands offering crossover clamps in southeast Asia. Research the reputation, history and reliability of each manufacturer.

- Material and build quality – compare the materials used in the construction of crossover clamps. Evaluate the build quality and durability of each option in relation to the regions challenging climate.

- Corrosion resistance – examine the corrosion resistance properties of each crossover clamp. This helps to determine their suitability for the humid and salty conditions of Southeast Asia.

- Load-bearing capacity – check the load-bearing capacity of the crossover clamps. This is in relation to the expected mechanical stresses from tension, wind and other factors.

- Ease of installation – compare the ease of installation for each option considering the skill level required and any specialized tools needed.

- Maintenance requirements – analyze the maintenance needs of each crossover clamp option. This includes how often the need to inspect, cleaned and replaced.

- Cost considerations – compare the cost of different crossover clamp options. this includes initial purchase costs and potential long-term savings through reduced maintenance needs.

Certifications and standards

Certifications and standards ensure the quality, safety and reliability of crossover clamps. Specific regulations vary by country but there are several international and regional standards that are commonly followed in each region. Ensure the selected crossover clamps comply with the relevant standards and local regulations. The following are the common standards and certifications in Southeast Asian countries.

- International Electrotechnical commission (IEC) – this standard provides specifications for fittings and accessories used in overhead lines and substation earthing.

- ASTM international – this specifies the salt spray (fog) testing procedure for evaluating the corrosion resistance of materials.

- IEEE standards– this specifies recommended practices for the maintenance and operation of substation equipment including fittings and hardware.

- ISO standards – this provides guidelines for the hot-dip galvanizing of iron and steel products ensuring corrosion protection.

- Local electrical standards – these are the local standards set by each of the southeast Asian country.

Regional market for crossover clamp in Southeast Asia

The regional market depends on the regions growing demand for reliable electrical infrastructure. It also depends on specific challenges posed by its diverse climates and environments. The market characterizes by the need for durable, corrosion-resistant and reliable solutions for the challenging environmental conditions. The following are the factors shaping the demand for crossover clamps in Southeast Asia.

- Rapid urbanization and industrialization in countries like Indonesia, Vietnam, Thailand and Malaysia are driving the need for expanded electrical infrastructure.

- The increasing demand for electricity due to population growth and economic development, requires the expansion of transmission and distribution networks. This leads to higher demand for crossover clamps.

- The push for renewable energy sources requires the installation of new transmission lines and the need for reliable crossover clamps.

- Expansion of cities and power distribution networks demands the reliable and efficient need for crossover clamps.

- The humid and variable climate of Southeast Asia pose challenges such as corrosion, humidity, temperature changes and strong winds. The crossover clamps help to withstand these conditions.

Frequently asked questions

Crossover clamps are components used to provide mechanical support and electrical continuity at points where two conductors cross each other. They help to maintain electrical continuity to ensure efficient and safe transmission of electricity without interruptions.

Climate of Southeast Asia characterizes by humidity, temperature variations, tropical storms and salt exposure. Crossover clamps resist rust, corrosion and prevent electrical contact in the transmission lines.

Signs of corrosion and wear on crossover clamps include discoloration, rust formation, flaking, cracks, loose fasteners, reduced smoothness or odor. Maintenance and inspection helps to ensure the safety, reliability and longevity of power transmission systems.