Insulated piercing clamp (IPC) is an electrical connector used to tap into or splice power distribution lines. It does so without the need of line interruption or conductor cutting. It has a design that provides a secure electrical connection while maintaining insulation between the main lines and the tap. They provide convenient and efficient solution for tapping into power distribution lines. They also offer a reliable electrical connection while maintaining insulator. This also hellps to ensure the integrity of the power distribution. The clamp creates a connection point for secondary power lines or install additional devices. Insulated piercing clamps work in applications where it is necessary to add secondary power lines or install equipment without interrupting the main power supply.

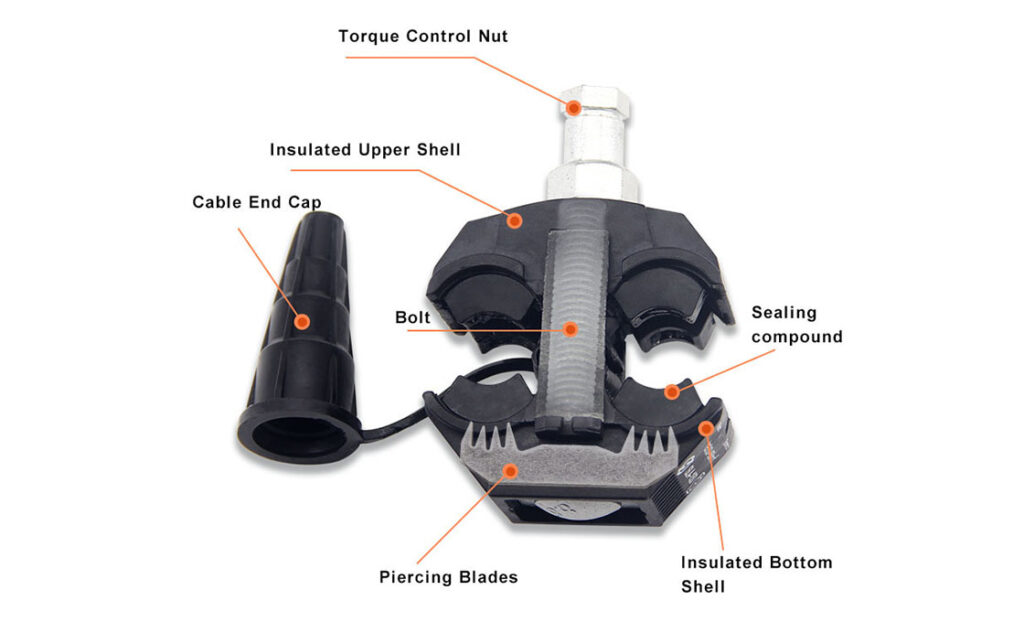

Components of the clamp

Insulated piercing clamps have a design that provide a safe and reliable method for tapping into power lines. The features work together to create a secure electrical connection that can support extra wiring and devices. They also protect against electrical hazards and environmental factors. Below are the main components of insulated piercing clamps.

- Piercing blade – the piercing blade is the main component of the clamp that penetrates the insulation of the power line. It is from a conductive material and has a sharp, pointed end to make a clean puncture through the insulation.

- Insulated housing – this is a non-conductive material made of plastic that encloses the piercing blade. It insulates the blade from the surrounding by preventing contact with other objects or persons.

- Clamping mechanisms – this helps to secure the clamp onto the power line. It may consist of a screw, bolt or other fasteners that can tighten to create a secure connection.

- Terminal connectors – the terminal connectors help to attextraonal wires or devices to the clamp. They consist of screw terminals, crimp connectors or other types of electrical connectors.

- Sealing components – some clamps include additional components for sealing the connection point. These include rubber gaskets or heat shrink tubing. They help protect the connection from moisture, dirt and other contaminants that could compromise the integrity of electrical connection.

Types of insulated piercing clamps

Designs of the clamps vary depending on the type of power line, voltage levels, installation requirements and local regulations. Also, consult with a qualified electrical professional to ensure proper selection and installation. The following re the common types of the insulated piercing clamps.

- Overhead line piercing clamp – this works in overhead power lines to tap into the main distribution line. This helps to create a connection point for secondary lines. They install devices like transformers, meters or communication equipment.

- Service Drop piercing clamp – these clamps help to tap into underground power cables. They also pierce the insulation of the cable while maintaining a secure and reliable electrical connection.

- Distribution line piercing clamp – distribution line clamps help in distribution networks to tap into medium-voltage power lines. They provide a safe and reliable connection for secondary lines or devices.

- Underground line piercing clamp – these clamps help to pierce the insulation of the cable while maintaining a secure and reliable electrical connection.

- Tension clamp – tension clamps work in applications that need to tap into tensioned power lines. They withstand the mechanical forces exerted on the power line.

Applications of the insulated piercing clamp

Insulated piercing clamps offer a versatile and non-destructive method for tapping into power lines. They allow for easy installation and modification of electrical connections. Insulated piercing clamps provide a flexibility in expanding power distribution systems. They enable the integration of extra circuits, equipment and monitoring devices. Discussed below are the various applications of the insulated piercing clamps.

- Street lighting – street lighting systems connect to power lines using insulated piercing clamps. The clamps provide a secure connection point for the street lighting circuits. This allows for efficient and reliable illumination.

- Secondary line installations – the clamps tap into existing power lines and create connection points for secondary lines. Secondary lines works in distributing power to extra buildings, installations or equipment.

- Temporary installations – insulated piercing clamps can help to create temporary connections to power sources. The include setting up power supply for outdoor events, construction sites or temporary connections to power sources.

- Metering and monitoring – the clamps install electrical meters and monitoring devices onto power lines. The clamps allow for accurate measurement of power consumption. It also includes monitoring of electrical parameters like voltage, current and power quality.

- Communication and signaling – insulated piercing clamps can tap into power lines for the installation of communication and signaling equipment. They include devices like telecommunication lines, data transmission equipment and traffic signal systems.

- Fault detection and repair – the clamps are sometimes used in fault detection and repair processes by tapping into power lines at specific points.

Installation of the clamps

The installation process can be a tedious process which could ease by following the manufacturer’s instructions and any applicable electrical codes. Additionally, it is advisable to consult a qualified electrician for assistance. This would help to ensure a safe and reliable installation. The following is a step-by-step installation process of the insulated piercing clamps.

- Gather all the necessary tools and equipment like clamps, connectors and other materials needed for installation.

- Follow the safety protocols like personal protective equipment and taking necessary precautions.

- Identify the appropriate location on the power line where the insulated piercing clamp will install. Factors include accessibility, clearance requirements and proximity to the intended connection points.

- Clean the portion of the power line where the clamp will attach. Remove any dirt, grease or debris that could interfere with the connection.

- Opening the insulated housing exposes the piercing blade inside which follows the manufacturer’s instructions for opening the clamp.

- Position the clamp onto the power line aligning the piercing blade with the desired insertion point. Ensure the blade aligns parallel to the direction of the conductor inside the power line to achieve a clean and effective puncture.

- Close the insulated housing of the clamp securing it in place around the power line. Use the appropriate tightening mechanism to securely fasten the clamp.

- Visually inspect the connection to ensure proper alignment and contact. Perform electrical tests or measurements to verify the integrity of the connection. Ensure there are no faults or loose connections.

- Use the provided terminal connectors following wiring practices. This helps to ensure a secure and reliable connection.

- Apply any sealing components like rubber gaskets or heat shrink tubing. This helps to protect the connection point from moisture, dirt and other environmental factors.

Choosing the best insulated piercing clamps

Insulated piercing clamps apply in different applications in the fields. You should consider several factors before choosing the best clamp for your applications. Different manufacturers in the market produce different types of clamps and specifications. You should consider the following factors when choosing the best clamps.

- Determine the specific applications for which you need the insulated piercing clamp. Consider factors such as overhead, voltage level and the purpose of the connection.

- Ensure that the piercing clamp is compatible with the type and size of the power line you are working with. Consider the material, diameter and insulation thickness. This helps to ensure proper fit and secure connection.

- Check the electrical rating of the insulated piercing clamp like voltage and current capacity.

- Choose a high-quality insulated piercing clamp from a reputable manufacturer. They should be from durable and reliable materials. This is to ensure long term performance and resistance to environmental factors.

- Consider features such as user-friendly mechanisms for opening and closing the clamp, clear alignment indicators and compatibility with standard installation tools.

- The clamps should meet the relevant industry standards and regulations for electrical installations. They provide assurance of quality, safety and compliance with legal requirements.

- Consider the technical support, documentation and warranty provided by the manufacturer.

- Evaluate the cost-effectiveness of the insulated piercing clamp. Consider its quality, features and performance.

Frequently asked questions

Insulated piercing clamps are types of electrical connector used in power distribution systems. They tap into existing power line without the need to cut or disconnect the line.

The insulated peircing clamps offer several benefits which include tapping into existing power lines, easy installation, cost effective, flexibility, reduced use of specialized tools and reusability.

The clamps also have several limitations to consider when selecting for your application. These include potential damage to the insulated material, compatibility limitations, potential entry points for moisture and installation skills are required.